OVERVIEW

PLASTIC COMPONENTS COMPANY

Plastic Components Manufacturing Company was established in 2017, covering over 4 hectares, with an investment capital of 165 million USD and an annual production capacity of 12,000,000 products, including plastic components for automotive and motorcycle industries, as well as industrial and civil plastic products.

With a system of modern equipment and machinery imported from Austria, South Korea, and Japan, the company utilizes four technologies in plastic production: injection molding, extrusion, blow molding, and plastic component painting, offering a diverse range of products. These products meet the demands of the domestic market, contributing to an increase in the localization ratio and enhancing the competitiveness of the Vietnamese automotive industry. Additionally, the company has exported to several major markets, including Australia, the United States, Malaysia, Canada, and Denmark.

2017

Establishment year

165 million USD

Investment capital

282 employees

Personnel

PRODUCTS

Automotive & motorbike plastic components

The company produces and supplies high-quality automotive and motorbike plastic components: bumpers, side trims, mudguards, luggage compartments, door trims, dashboards, consoles, spoilers, side lights and ceiling lights, speedometer cover assembly, bumper trims,...

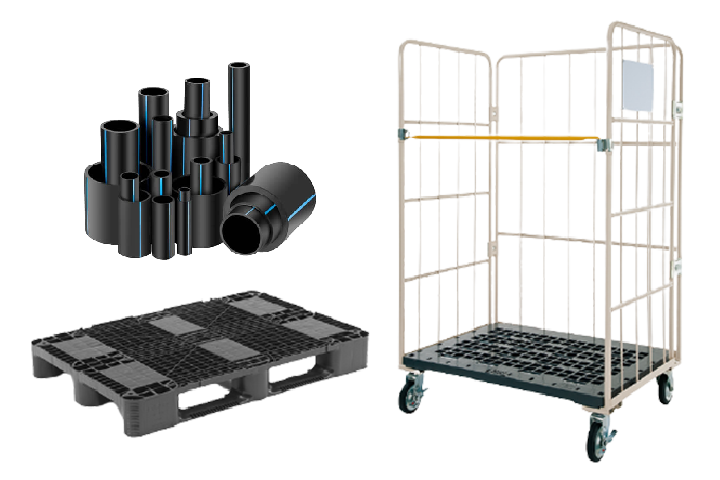

Industrial plastic components

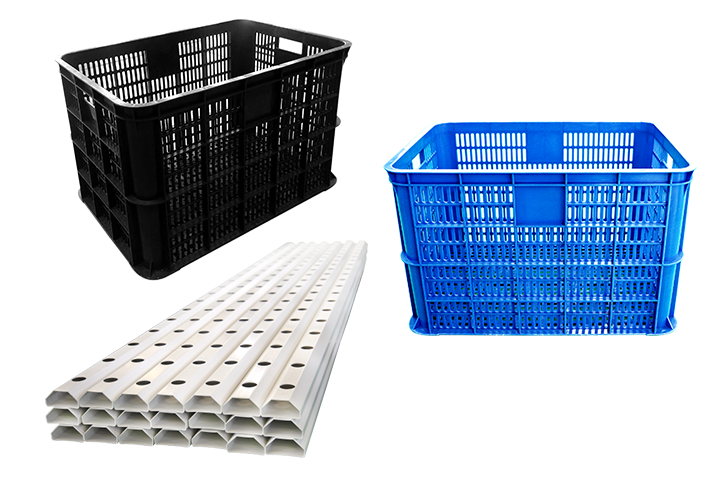

The company manufactures and supplies products for the industrial sector, including plastic tanks, plastic pallets, HDPE plastic tubes, plastic core spun threads, wall fan plastic components, cable ducts, and more.

Agricultural plastic components

The company manufactures and supplies products for the agricultural sector, including rubber latex collection tools, plastic baskets, hydroponic plastic tubes, and plastic banana containers and more.

Civil plastic components

The company produces and supplies civil plastic products such as: plastic cans, plastic bottles, plastic parts for treadmills, plastic tanks...

PRODUCTION PROCESS

Plastic injection line

-

Capacity: 6,000,000 products/year.

-

The production line features 19 fully automatic plastic injection molding machines, comprising 2 machines of 3,200 tons, 1 machine of 2,000 tons, 1 machine of 1,400 tons, and 15 machines with capacities ranging from 85 tons to 900 tons. These machines are imported from Austria and South Korea and include an automatic plastic drying mode, a self-feeding material system, and a touch screen control panel.

-

The products from the production line include: automotive and motorbike plastic components (car bumpers, pickup bumpers, spoilers, door trims, dashboards, luggage compartments…), industrial and civil plastic products/components (plastic pallets, plastic crates, wall fan plastic components, plastic tanks…).

CERTIFICATES

The company has obtained certification for the Quality Management System IATF 16949:2016, ISO 9001:2015, and the Environmental Management System ISO 14001:2015. The products meet the stringent standards of both domestic and export customers.