Overview

AUTOMOTIVE ELECTRICAL EQUIPMENT COMPANY

Automotive Electrical Equipment Manufacturing Company was established in 2024, covering an area of 20,000 m², with an investment capital of USD 40 million and an annual capacity of 200,000 sets.

With state-of-the-art production lines, machinery, and equipment imported from South Korea, Germany, and Singapore, the company specializes in manufacturing and supplying wire harnesses, components, and electronic equipment for passenger cars. Its products meet the needs of domestic partners and are also exported to South Korea. The company continues to invest in enhancing productivity and product quality, aiming to develop new products and expand into the North American and European markets.

With state-of-the-art production lines, machinery, and equipment imported from South Korea, Germany, and Singapore, the company specializes in manufacturing and supplying wire harnesses, components, and electronic equipment for passenger cars. Its products meet the needs of domestic partners and are also exported to South Korea. The company continues to invest in enhancing productivity and product quality, aiming to develop new products and expand into the North American and European markets.

2024

Establishment

40 million USD

Investment capital

200,000 sets/year

Capacity

Products

Passenger car wire hardness

The company manufactures and supplies wire harnesses for various passenger car models. Products are manufactured using automated technology and undergo rigorous quality control at every stage, meeting the international standards of automotive brands such as Kia and Hyundai.

View all products

Passenger car components & electronic equipment

The company provides high-quality components and electronic equipment for passenger cars such as air conditioners, AVN systems, backup cameras, and dashboard cameras.

View all products

Production technology

Cutting & crimping line

- The cutting & crimping line is equipped with automatic equipment imported from Korea, such as Auto cutting & crimping machines, Auto cutting & striping machines, Twisting machines, Tube heat machines, and Ultrasonic machines…, to enhance operational flexibility, minimize errors, save time, and boost production efficiency.

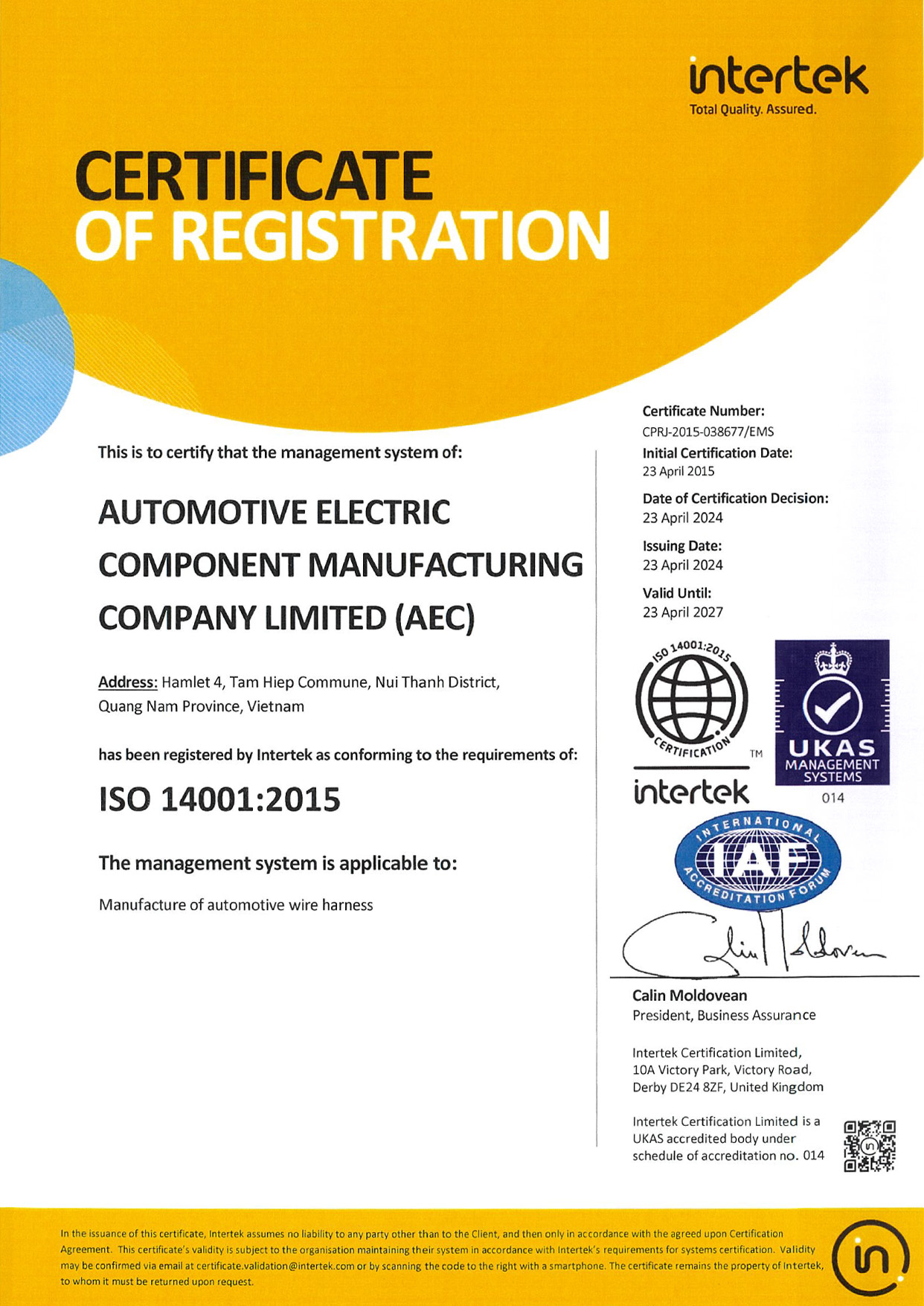

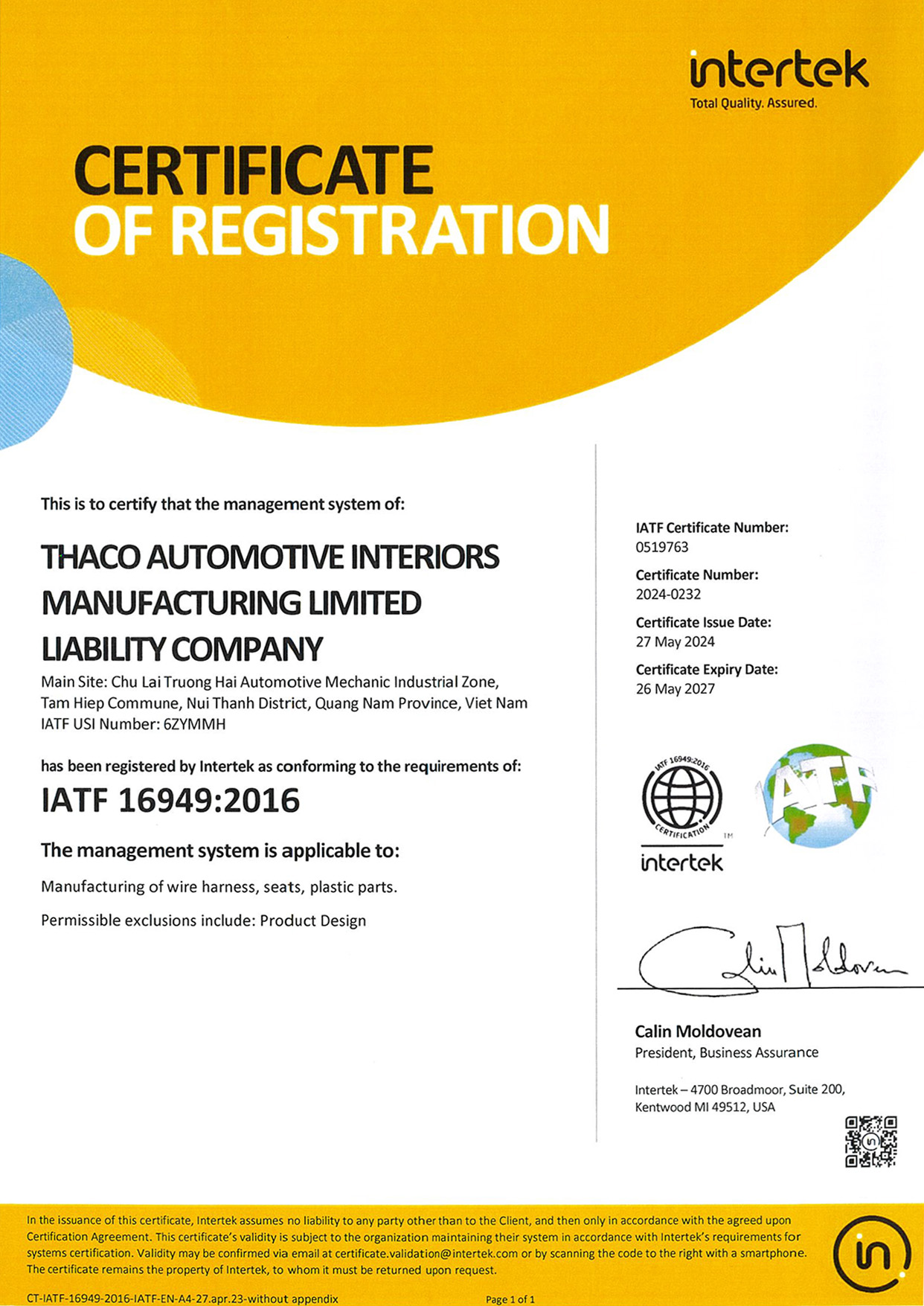

Certificates

The company has obtained certification of the Quality Management System IATF 16949:2016, ISO 9001:2015, and the Environmental Management System ISO 14001:2015. Additionally, its products undergo strict quality control from input to output, adhering to Hyundai-Kia Motors Corporation standards.