Product information

Trusted Auto Body Parts Supplier for Global OEMs

In today’s automotive manufacturing landscape, selecting reliable auto body parts suppliers requires a strong focus on quality consistency, production capability, and supply stability. The right partners help OEMs and aftermarket brands meet safety requirements, maintain product durability, and ensure consistent output across global markets. This article outlines practical criteria and industry insights from THACO INDUSTRIES to support informed supplier selection.

Evolving demand in body parts supply

The automotive industry is rapidly evolving, and this transformation has reshaped the expectations placed on modern body parts. The rise of electric vehicles (EVs), the adoption of lightweight materials, and the shift toward modular vehicle platforms have increased the technical complexity of body components, turning them into critical elements for safety, efficiency, and structural performance.

In European markets such as the UK, Germany, Italy, and Spain, OEM manufacturers are placing greater emphasis on:

- Crash safety performance, with stricter requirements for energy absorption and structural integrity

- Corrosion resistance, especially for vehicles operating in harsh weather and coastal environments

- Brand-specific body design, where exterior panels contribute directly to brand identity and product differentiation

As a result, body parts suppliers are now expected to deliver not only manufacturing capability, but also engineering support, material expertise, and the flexibility to meet evolving OEM standards.

Critical evaluation factors when selecting a body parts supplier

When selecting an auto body parts supplier, OEMs and Tier-1 manufacturers must evaluate technical capability, process control, quality assurance, and long-term production stability to ensure that every component meets stringent safety, performance, and brand expectations.

High-precision fabrication & structural performance

Body panels, pillars, cross-members, and rails are critical structural components that must maintain tight dimensional tolerances while delivering high mechanical strength. A qualified supplier must demonstrate advanced manufacturing and engineering capabilities, including:

- Robotic and automated welding for consistent joint quality

- Automatic die-pressing and progressive stamping for repeatable accuracy

- 3D coordinate measurement systems (CMM) for geometry verification

- Virtual crash simulation and structural validation tools

These technologies reduce dimensional variation and ensure predictable performance under real-world impact conditions.

Surface protection & durability

European road environments expose vehicles to moisture, road salt, wide temperature fluctuations, and long service cycles. To ensure long-term durability, suppliers must implement robust surface protection systems, including:

- Galvanising for deep corrosion resistance

- E-coating (electrophoretic painting) for uniform internal coverage

- Powder coating for mechanical strength and aesthetic stability

- Salt-spray and corrosion testing to validate coating performance against EU durability benchmarks

Strong surface engineering directly impacts product lifespan and warranty performance.

Material innovation & weight optimisation

Lightweight construction is now a strategic priority, particularly for electric and hybrid vehicles. Modern body parts production increasingly relies on:

- High-strength steel (HSS) and advanced high-strength steel (AHSS)

- Aluminium alloys for critical structural and exterior components

- Selected composite materials for specific load-bearing or impact-resistant zones

Advanced forming and joining technologies such as hydroforming, laser trimming, and multi-material joining allow suppliers to reduce mass while maintaining stiffness and crash safety.

Competitive production & global supply-chain readiness

A strong supplier must balance cost efficiency with operational reliability. This includes:

- Stable, scalable mass-production capability

- On-time delivery performance supported by capacity planning

- In-house logistics coordination and export-ready packaging design

- EU-compliant documentation for seamless customs clearance

These capabilities allow OEMs to minimize supply-chain risk while maintaining production flow.

Regulatory compliance & traceability

Compliance has become a mandatory requirement and a core supplier qualification criterion for global OEM sourcing. A qualified body parts supplier should support:

- ISO 9001:2015 and IATF 16949:2016 for automotive quality systems

- Structural and fabrication standards such as EN 1090

- Environmental compliance including ISO 14001:2015, RoHS and REACH

In parallel, transparent traceability systems must track part numbers, batch records, heat numbers, and material certificates to support OEM audits, warranty investigations, and regulatory inspections.

Typical product range offered by body-parts suppliers

Modern auto body parts suppliers must support multi-platform vehicle architectures and scalable production programs. Their portfolios typically cover both structural and aesthetic components, designed to meet mechanical performance, dimensional stability, and brand-specific requirements.

Exterior structural components

Typical exterior components include door skins, hoods, fenders, roofs, and tailgates, manufactured with high surface accuracy and tight dimensional tolerances to ensure seamless assembly compatibility. These components are engineered for impact resistance, corrosion protection, and long-term surface durability.

Underbody & chassis body modules

Underbody structures are critical to structural stiffness, occupant safety, and vibration control. Typical components include floor panels, side rails, structural reinforcements, and pillars, designed to meet strict crash-performance and NVH (noise, vibration, harshness) requirements. These modules must deliver high load-bearing capability while keeping overall weight under control.

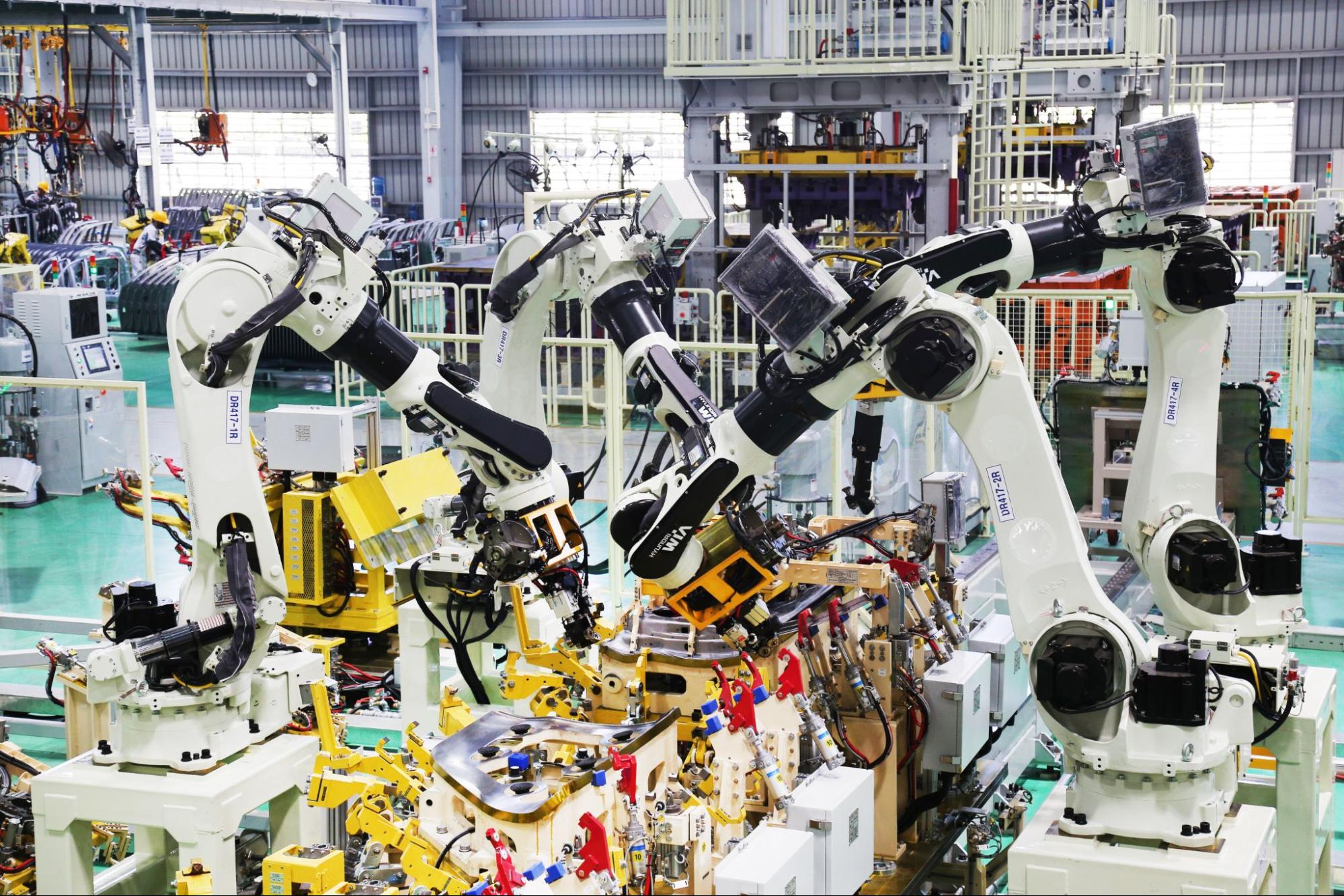

Body-in-White (BIW) modules

BIW assemblies comprise fully welded or partially welded body structures supplied directly to OEM production lines for seamless integration. These modules are delivered ready for paint shop operations and final assembly, ensuring dimensional stability and consistent joint quality. By outsourcing BIW modules, OEMs can reduce in-house welding complexity, streamline tooling requirements, and increase overall production line efficiency.

Plastic & composite body parts

To support lightweight vehicles and modern styling, suppliers provide bumpers, grilles, mirror housings, trims, and aerodynamic covers made from engineering-grade plastics or composite materials. These parts are designed for reduced mass, improved corrosion resistance, and high-quality surface finish, while maintaining structural integrity in daily use.

Custom OEM/ODM body solutions

Leading suppliers offer tailor-made body components developed according to OEM technical drawings and functional requirements. This includes custom brand-specific colors, proprietary mounting interfaces, specialised materials, and integrated fastening solutions. These custom development programs enable model differentiation, accelerate platform development timelines, and ensure long-term production scalability for OEMs and Tier-1 manufacturers.

Target markets & industry applications

Demand for high-quality body components is growing across automotive and mobility segments. Reliable auto body parts suppliers support diverse applications where precision, durability, and regulatory compliance are essential.

OEMs and Tier-1 Manufacturers (Passenger Cars & Light Commercial Vehicles)

Across the UK, Germany, Italy, and Spain, automotive OEMs require body and BIW components with high structural rigidity, tight dimensional tolerances, and seamless compatibility with high-speed, automated production lines.These customers prioritize repeatability, crash performance, and surface quality to maintain consistent vehicle standards.

Electric Vehicle (EV) & Battery Housing Manufacturers

EV platforms introduce new structural challenges, particularly around battery protection and thermal management. Suppliers address these requirements with lightweight, high-strength body structures engineered to protect battery packs, enhance vehicle range, and comply with stringent EV safety regulations.

Bus, Coach & Commercial Vehicle Producers

Heavy-duty vehicle manufacturers require large-format body modules engineered for extended service life, high passenger capacity, and continuous high-load operating conditions. Components in this segment must provide high structural rigidity along with enhanced vibration and long-term fatigue resistance.

Aftermarket Distributors & Independent Assemblers

Beyond OEM production, precision-engineered body components are also supplied to aftermarket distributors that require specification-compliant parts with consistent dimensions and full traceability. In this segment, standardized quality, clear part identification, and lot-level traceability are essential for efficient inventory management and long-term market reliability.

Why partner with THACO INDUSTRIES as your auto body parts supplier?

Partnering with THACO INDUSTRIES means working with a leading industrial manufacturing corporation in Vietnam, with over two decades of experience in mechanical engineering and supporting industries. The corporation delivers OEM/ODM solutions through integrated production systems, strong engineering expertise, and full compliance with international standards. The corporation specializes in engineering and manufacturing high-precision automotive body and chassis components for passenger cars, trucks, and buses. Our products are supplied to globally recognized OEMs, including brands such as Kia and Mazda.

THACO INDUSTRIES has invested in a dedicated Automotive Chassis and Body Parts Manufacturing Plant, with a total investment of USD 50 million and a facility area of 50,000 m², delivering industrial-scale capacity and stable, reliable production performance, including:

- Up to 200,000 sets of car body components annually

- 100,000 truck chassis sets per year

- 5,000 bus body sets per year

- 500,000 mechanical components annually

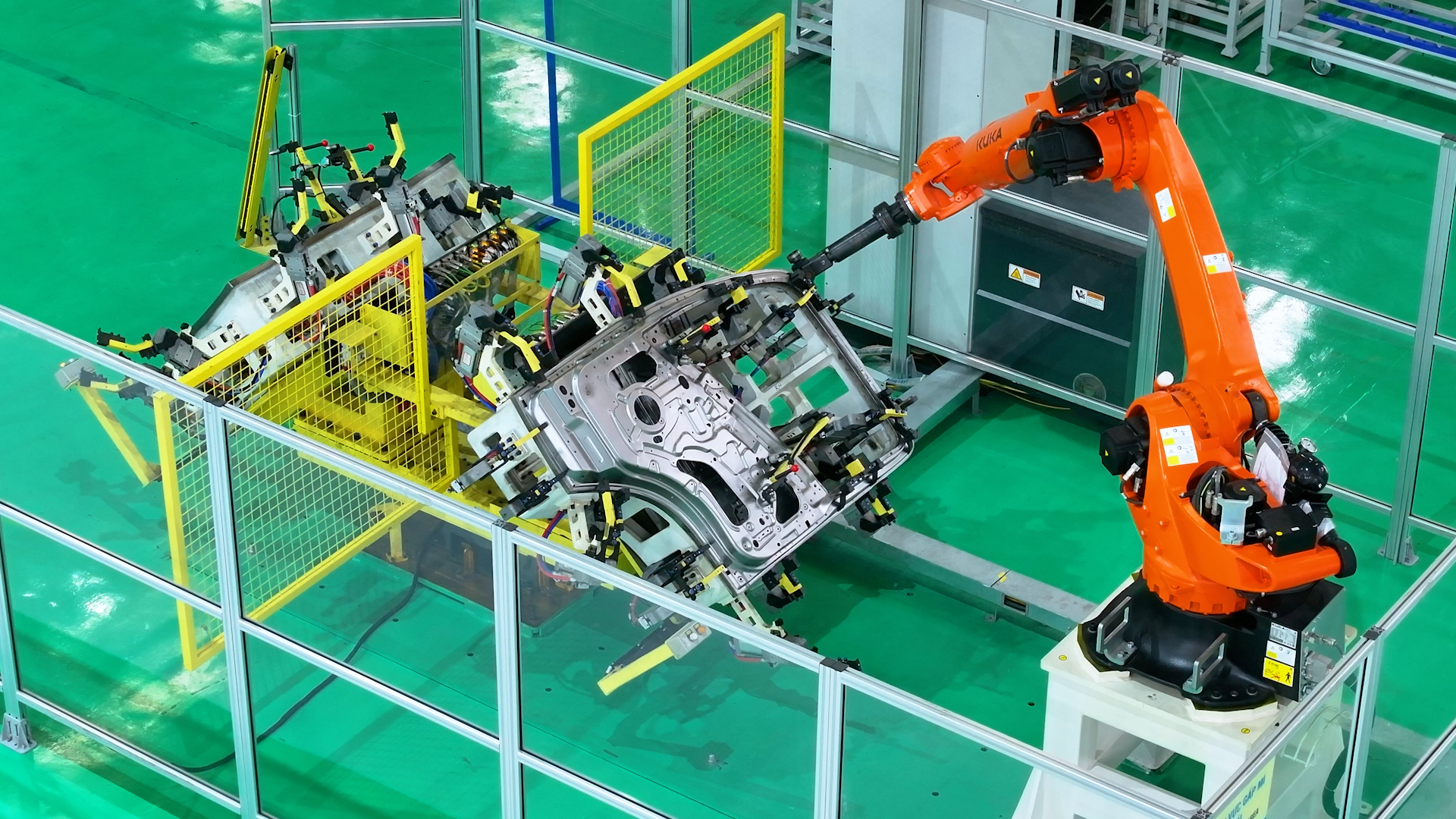

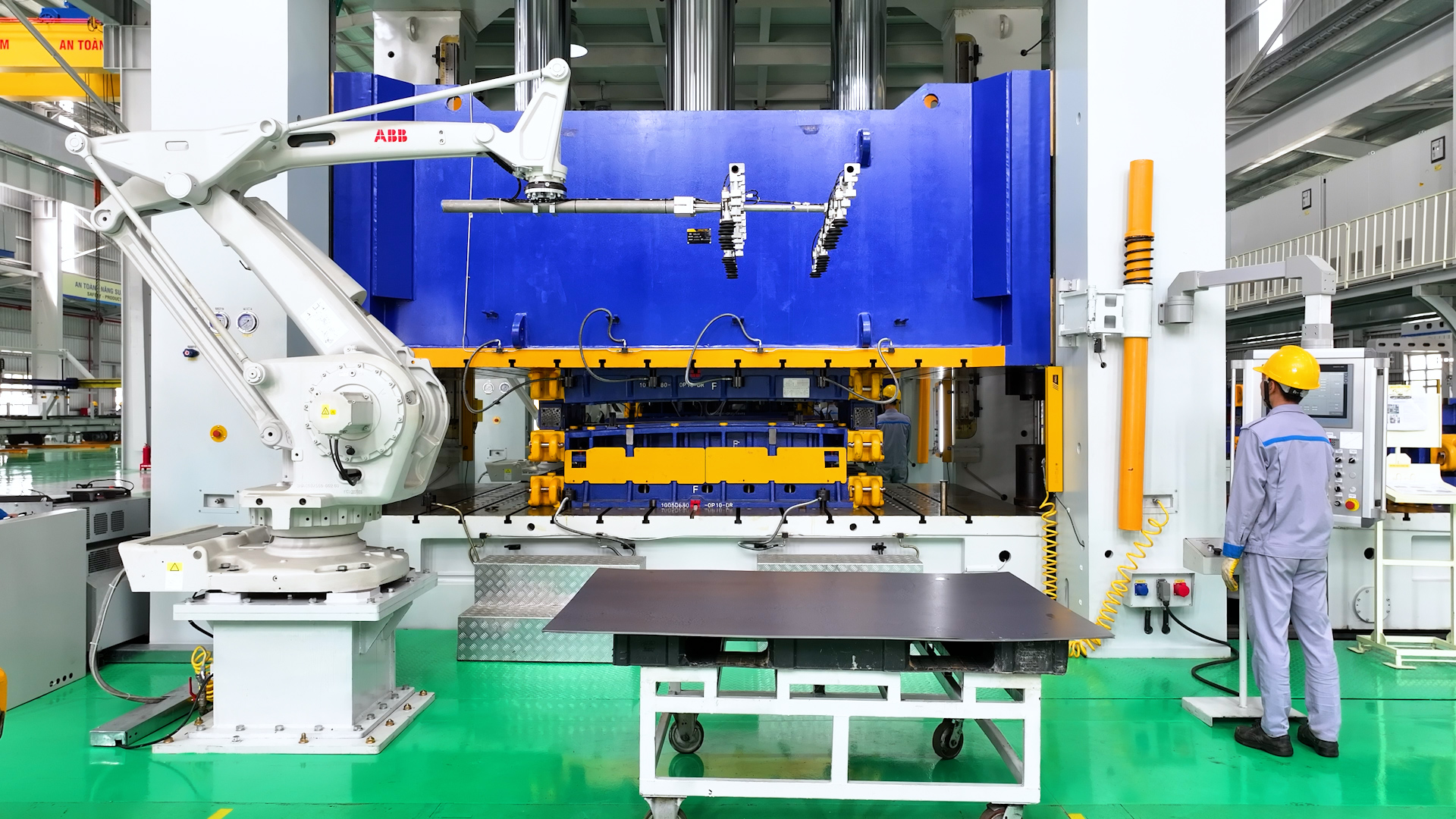

Production is supported by high-tonnage, automated equipment, such as:

- Tandem press lines with robotic feeding systems (up to 1,600 tons)

- South Korea–sourced passenger car hemming lines with sealing, welding, and hemming robots

- 6,300-ton chassis beam stamping systems for extra-long structural members

- 1,000-ton stamping machines for large-format body panels

Beyond capacity, THACO INDUSTRIES delivers consistent OEM-grade quality through full compliance with IATF 16949:2016, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, CE Marking, and RoHS/REACH. Every component is manufactured with tight tolerance control, validated durability, and full regulatory traceability to meet European and global OEM expectations.

The corporation operates a fully integrated, end-to-end manufacturing value chain covering material processing, welding, surface treatment and painting, final assembly, packaging, and export-ready delivery. This integrated approach enables OEMs and Tier-1 suppliers to reduce supplier complexity, shorten lead times, and improve overall cost predictability. Engineering teams leverage CAE and 3D simulation tools to optimise structural weight, enhance performance, and improve manufacturing efficiency, supporting lightweight body-part part development and scalable, cost-effective scalability.

Leveraging THACO’s multi-industry ecosystem and integrated logistics capabilities, THACO INDUSTRIES provides flexible, multimodal delivery solutions under Incoterms such as FOB, CIF, FCA, DAP, and DDP. This end-to-end approach enables faster customs clearance, reduced logistics costs, and shorter delivery lead times, helping partners streamline cross-border operations and optimize supply chain efficiency.

The corporation is committed to sustainable manufacturing and long-term partnerships. This commitment is supported by continuous capacity expansion and ongoing investment in new technologies. In parallel, THACO INDUSTRIES co-develops next-generation body-part solutions aligned with OEM requirements, strengthening long-term supply partnerships with global automotive manufacturers.

For tailored OEM engineering solutions or partnership discussions, contact THACO INDUSTRIES at partsales@thaco.com.vn or hotline +84 348 620 063. Our team is ready to support your technical requirements and explore long-term collaborative opportunities.