OVERVIEW

MOLDS COMPANY

Mold Manufacturing Company was established in 2016, covering an area of 4,400 m² with an investment capital of 50 million USD. The company has invested in modern production lines featuring equipment imported from Germany, Japan, and South Korea, meeting an annual capacity of 1,000 mold sets and 3,000 tons of precision mechanical components.

The company specializes in manufacturing and supplying various types of molds, including plastic injection molds; stamping dies (blanking die, forming die, stretch forming punch, combination die...); extrusion molds; extrusion blow molds; and precision mechanical processing. Products are available in a wide range of types and sizes, serving diverse sectors such as automotive, industrial, agricultural, and household.

With a team of professional designers, engineers and experts trained in South Korea, the company continues to research and develop new products such as PU foam molds and heat press molds. At the same time, it actively expands its supply to domestic customers and export markets including the United States, Canada, and South Korea.

The company specializes in manufacturing and supplying various types of molds, including plastic injection molds; stamping dies (blanking die, forming die, stretch forming punch, combination die...); extrusion molds; extrusion blow molds; and precision mechanical processing. Products are available in a wide range of types and sizes, serving diverse sectors such as automotive, industrial, agricultural, and household.

With a team of professional designers, engineers and experts trained in South Korea, the company continues to research and develop new products such as PU foam molds and heat press molds. At the same time, it actively expands its supply to domestic customers and export markets including the United States, Canada, and South Korea.

2016

Establishment year

50 million USD

Investment

166

Employees

PRODUCTS

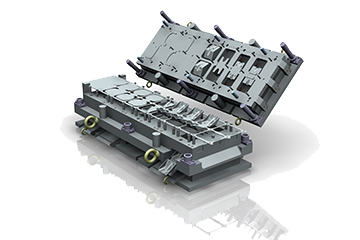

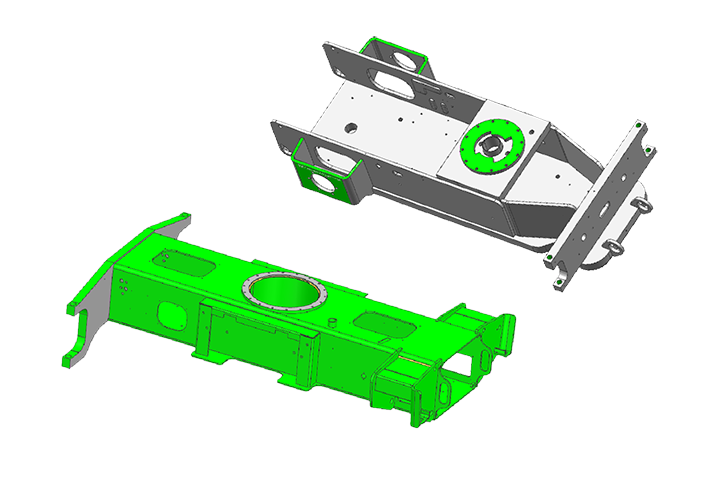

Stamping die

The company specializes in manufacturing high-quality stamping dies for automotive components such as: passenger car sunroof frame stamping die, passenger car chair frame stamping die, truck front pipe exhaust hanger progressive die, truck chassis frame stamping die, truck compressed air tank stamping die, bus reinforce lamp frame part stamping die,...

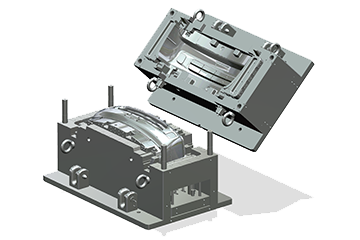

Plastic injection mold

The company specializes in manufacturing plastic injection molds for automotive components such as: passenger car cover bumper mold, passenger car luggage trim mold, truck front bumper mold, truck & bus grille mold, bus wheel rim cover mold... The company is researching and developing new products such as PU foam molds and heat press molds,...

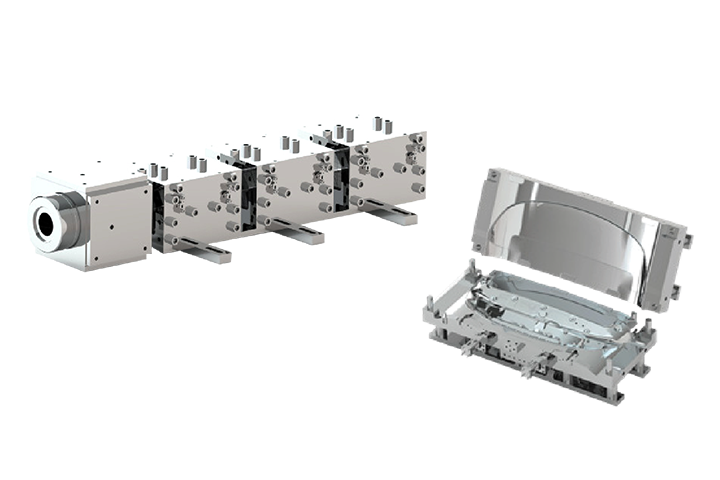

Extrusion mold - extrusion blow mold

The company specializes in manufacturing extrusion molds and extrusion blow molds such as: extrusion mold for trim part, extrusion blow mold for spoiler passenger car, hard shell gel ice pack mold, hydroponically pipe mold,... meeting all customer-specific requirements.

Precision mechanical processing

The company provides precision mechanical processing service for a wide range of products such as passenger car body part welding jigs, STS crane parts, lifter parts, E-RTG crane parts, portal crane parts, and more.

PRODUCTION TECHNOLOGY

Six-face machining area

- The six-face machining area is equipped with advanced and modern machinery such as 4-face milling machines, grinding machines,… capable of processing workpiece weighing up to 750 kg into highly precise six-face square and flat workpiece before being transferred to CNC machining area.

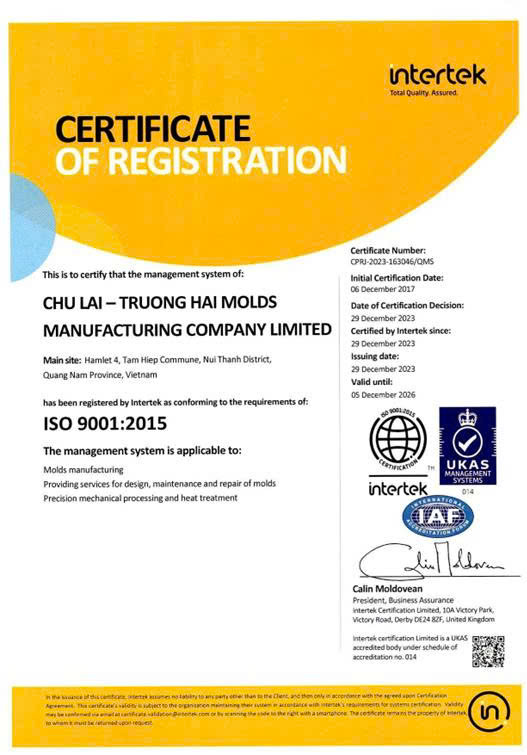

CERTIFICATES

The company has obtained certification for its Quality Management Systems (ISO 9001:2015, IATF 16949:2016) and its Environmental Management System (ISO 14001:2015). Its products meet the stringent requirements of both domestic and export customers.