OVERVIEW

AUTOMOTIVE SPRINGS COMPANY

The Automotive Spring Manufacturing Company was established in 2015, covering an area of 2 hectares with a total investment of 25 million USD and an annual capacity of 12,000 tons. This includes multi-leaf springs for light trucks, medium-duty trucks, heavy-duty trucks, semi-trailers, and aftermarket leaf springs.

Produced on an advanced technology production line with an automated system of machinery and equipment, and utilizing materials along with a design and inspection process in accordance with Japanese standards (JIS G 4801; JIS B 2710; JASO C 601 & JASO C 604), the company's products are of high quality, ensuring elasticity, durability, good load capacity, and smooth operation while meeting the requirements for operation on various terrains. In addition to serving the domestic market, the company has exported products to the USA, Australia, Canada, Germany, Dominica, South Korea...

Produced on an advanced technology production line with an automated system of machinery and equipment, and utilizing materials along with a design and inspection process in accordance with Japanese standards (JIS G 4801; JIS B 2710; JASO C 601 & JASO C 604), the company's products are of high quality, ensuring elasticity, durability, good load capacity, and smooth operation while meeting the requirements for operation on various terrains. In addition to serving the domestic market, the company has exported products to the USA, Australia, Canada, Germany, Dominica, South Korea...

2015

Establishment year

25 million USD

Investment capital

12,000 tons/year

Capacity

PRODUCTS

Multi-leaf springs for truck

The company manufactures and supplies OEM multi-leaf springs for light, medium, and heavy trucks from brands such as Kia, Isuzu, and Foton. The product matches the quality of springs produced in Korea.

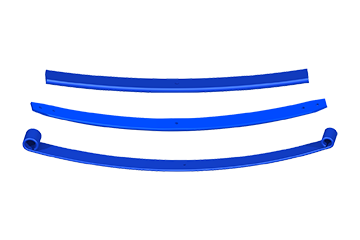

Multi-leaf springs for semi-trailers

The company manufactures and supplies multi-leaf springs for semi-trailers, including 3-leaf, 4-leaf, 7-leaf, and 9-leaf springs. These springs offer advantages such as high durability, excellent load-bearing capacity, and smooth operation.

Aftermarket leaf springs

The company manufactures and supplies a variety of leaf springs for after-sales service, including straight leaf springs, eye-rolling leaf springs, tapering leaf springs, and tapering - end trimming - hole punching leaf springs. Additionally, the company produces according to the specific requirements of its partners.

PRODUCTION PROCESS

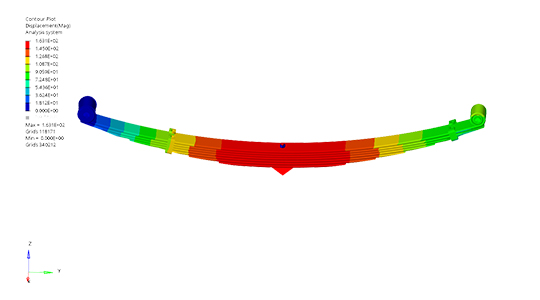

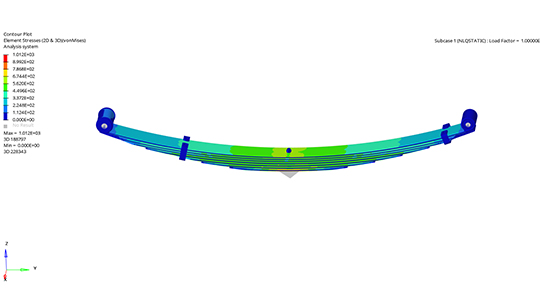

Design & simulation

-

Design drawings.

-

2D, 3D simulation

-

Descript, overview and detail calculate products, and optimize the production process.

CERTIFICATES

The company has obtained certification for the Quality Management System IATF 16949:2016, ISO 9001:2015 and the Environmental Management System ISO 14001:2015. The products meet the strict standards of both domestic and export customers.