News

THACO INDUSTRIES Pursues Leadership in Steel Structure and MEP

Implementing of THACO’s multi-industry development strategy, THACO INDUSTRIES (a sub-holding that operating in Mechanics & Supporting industries) has significantly intensified its investment in the steel structure and MEP (Mechanical, Electrical and Plumbing) sector, aiming to become the leading general contractor in Vietnam. The corporation is progressively asserting its position in the market through high-quality construction projects that meet both technical and aesthetic requirements.

Outstanding design, processing and installation capability

THACO INDUSTRIES owns the leading Mechanical Complex in Vietnam with a reserves capacity of 200,000 tons of steel, a processing capacity exceeding 50,000 tons per year, and steady financial & human resources. Therefore, it can undertake megastructures and projects with diverse scales.

To ensure high accuracy and aesthetics, THACO INDUSTRIES has invested in modern design and simulation software such as Tekla Structures, Sap2000, AutoCAD… These tools facilitate assessing and predicting project risks and performance more easily and quickly, ensuring full compliance with technical standards and meeting customer requirements. Furthermore, THACO INDUSTRIES owns a team of well-trained employees, experts, and engineers with extensive experience.

The corporation places particular emphasis on applying automated technology imported from Australia, Switzerland, Japan, and South Korea, including Slitting lines, Cutting lines (Fiber Laser machine, CNC Oxy Gas & Plasma cutting machine), Pressure processing lines (bending, punching, stamping), 100 automated welding robots, and 3-in-1welding technology (welding – hole drilling – compressing), as well as surface treatment lines (shot blasting, ED dipping, powder coating).

In addition, THACO INDUSTRIES applies modern project management software to optimize supply chains and monitor project progress. This software automatically detects errors and unexpected incidents in production, ensuring that all resources, such as raw materials and labor, are utilized efficiently.

The corporation strictly follows the TCVN 10307:2014 standard (Steel structure – General Specifications for manufacturing, installing, and acceptance) and TCXDVN 170:2007 standard (Steel structures – Fabrication, assembly, check and acceptance – Technical requirements) in processing and installation.

Vietnamese leading general contractor in providing comprehensive solutions for steel structure and MEP system

With outstanding design and manufacturing capabilities, THACO INDUSTRIES aims to become the leader in the design, processing, and installation of steel structures and MEP systems in Vietnam. The corporation offers comprehensive solutions, from design and processing to installing and maintaining steel structure and MEP system for industrial, commercial, and civil projects…

THACO INDUSTRIES can design, construct, and install metal structures, technological production lines, machinery, and equipment for buildings and factories. Besides, the Corporation provides Electrical Systems, Fire Protection Systems, Heating, Ventilation, Air Conditioning (HVAC) systems, wastewater treatment, water supply and drainage systems, and compressed air systems.

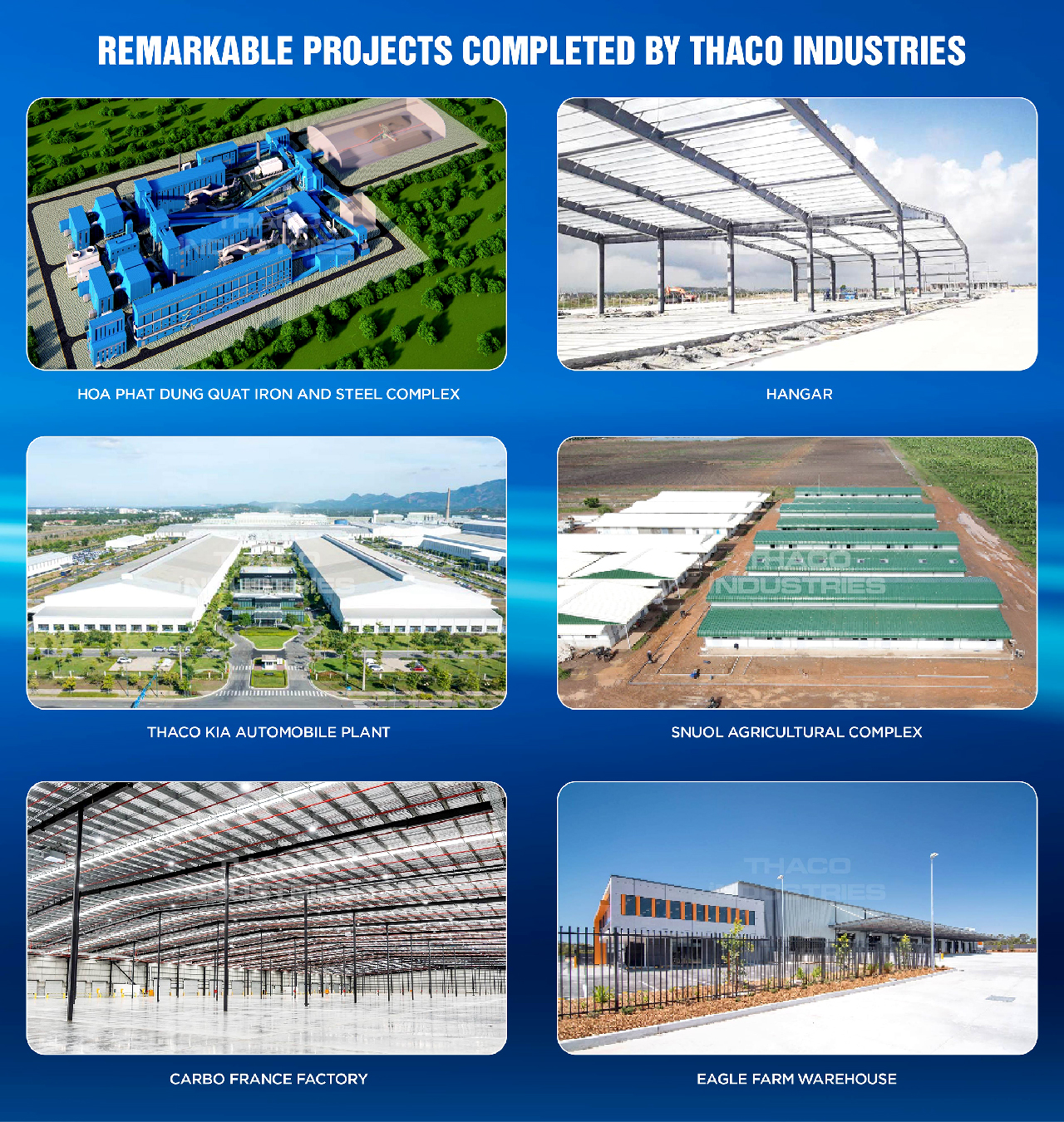

THACO INDUSTRIES has become a strategic partner of large enterprises such as Hoa Phat, Doosan, Dinco, Dai Quang Minh, and PTSC Quang Ngai. Up to now, the corporation has completed over 100 remarkable projects in Vietnam and overseas, including Hoa Phat Pellet Sintering 2 Factory – Quang Ngai province, Ba Son Bridge – Ho Chi Minh city, Chu Lai Overpass – Quang Nam province, STS Crane Platform for Doosan, steel structure for Nghi Son 2 Thermal Power Plant, THACO Chu Lai Office, Mechanical Complex, manufacturing plants, car showrooms, Snoul Agricultural Complex – Cambodia, Carbo France Factory – France, Eagle Farm Warehouse – Australia, and Aircraft Hangar at Chu Lai Airport – Quang Nam.