OVERVIEW

AUTOMOTIVE ELECTRICAL EQUIPMENT COMPANY

Automotive Electrical Equipment Manufacturing Company was established in 2024, covering an area of 40,000 m², with an investment capital of USD 40 million and an annual capacity of 215,000 sets.

With state-of-the-art production lines, machinery, and equipment imported from South Korea, Germany, and Singapore, the company specializes in manufacturing and supplying wire harnesses for passenger cars, buses, trucks and commercial vehicles.

The Automotive Electrical Equipment Manufacturing Company mass-produces fully tested, compliant wire harness assemblies for leading automotive brands such as Kia and Hyundai and for Sharp air purifier applications, leveraging modern, integrated production lines and certified quality systems (ISO 9001:2015, IATF 16949:2016, ISO 14001:2015) to ensure stable output and support expansion from Vietnam to ASEAN and other global markets such as American, Europe.

With state-of-the-art production lines, machinery, and equipment imported from South Korea, Germany, and Singapore, the company specializes in manufacturing and supplying wire harnesses for passenger cars, buses, trucks and commercial vehicles.

The Automotive Electrical Equipment Manufacturing Company mass-produces fully tested, compliant wire harness assemblies for leading automotive brands such as Kia and Hyundai and for Sharp air purifier applications, leveraging modern, integrated production lines and certified quality systems (ISO 9001:2015, IATF 16949:2016, ISO 14001:2015) to ensure stable output and support expansion from Vietnam to ASEAN and other global markets such as American, Europe.

2024

Establishment

40 million USD

Investment capital

215,000 sets/year

Capacity

PRODUCTS

Passenger car wire harness

Internationally recognized for its wiring harness expertise, THACO INDUSTRIES manufactures a wide range of harness systems for ICE vehicles and is expanding its capabilities through R&D solutions for hybrid and electrified platforms.

Our harness assemblies offer strong platform compatibility and meet localization requirements while maintaining the precision engineering standards demanded by global automakers.. We currently produce main, front, control, and roof wire harnesses, as well as those for the driver's side, rear bumper, airbag, and left- and right-hand floor components. Our range of wire harnesses serves 11 Kia models (including Morning, K3, Seltos, Sportage, etc.) and an expanding list of Hyundai vehicles.

Our harness assemblies offer strong platform compatibility and meet localization requirements while maintaining the precision engineering standards demanded by global automakers.. We currently produce main, front, control, and roof wire harnesses, as well as those for the driver's side, rear bumper, airbag, and left- and right-hand floor components. Our range of wire harnesses serves 11 Kia models (including Morning, K3, Seltos, Sportage, etc.) and an expanding list of Hyundai vehicles.

Commercial vehicle & bus wiring harness

THACO INDUSTRIES manufactures wiring harness solutions for commercial vehicles and buses, engineering and manufacturing robust main, engine, roof, door, and rear harnesses for OEM fleets. Built on advanced cutting, crimping, ultrasonic welding, and rigorous inspection (circuit testing, pull tests, micrograph analysis), THACO INDUSTRIES wiring harnesses are produced to support reliable, safe passenger and cargo transport across domestic and export programs.

Truck wiring harness

For trucks, THACO INDUSTRIES produces truck wiring harnesses that can handle high loads and extreme temperatures. Each assembly is fully traceable and meets international standards, ensuring electrical stability under demanding operating conditions.

Electric bicycle & golf cart wire harness

THACO INDUSTRIES produces durable wiring harnesses for motorcycles, electric bicycles and electric golf carts. Each unit is constructed with certified materials, rigorously tested for safety, and meets the standards of a trusted electrical wiring harness manufacturer.

Household wiring harnesses

THACO INDUSTRIES manufactures appliance wire harnesses for air conditioners, refrigerators and air purifiers, leveraging automotive-grade plants and standards for reliable, export-ready quality.

PRODUCTION TECHNOLOGY

R&D Activities

- As a reputable automotive wiring harness manufacturer, THACO INDUSTRIES places strong emphasis on research and development. Our R&D activities focus on adopting design tools, enhancing manufacturing processes, and developing innovative and cost-effective harness solutions. Engineers follow a structured workflow that includes information analysis, product design, sample preparation, and checking, to standardize procedures, optimize costs, and boost productivity.

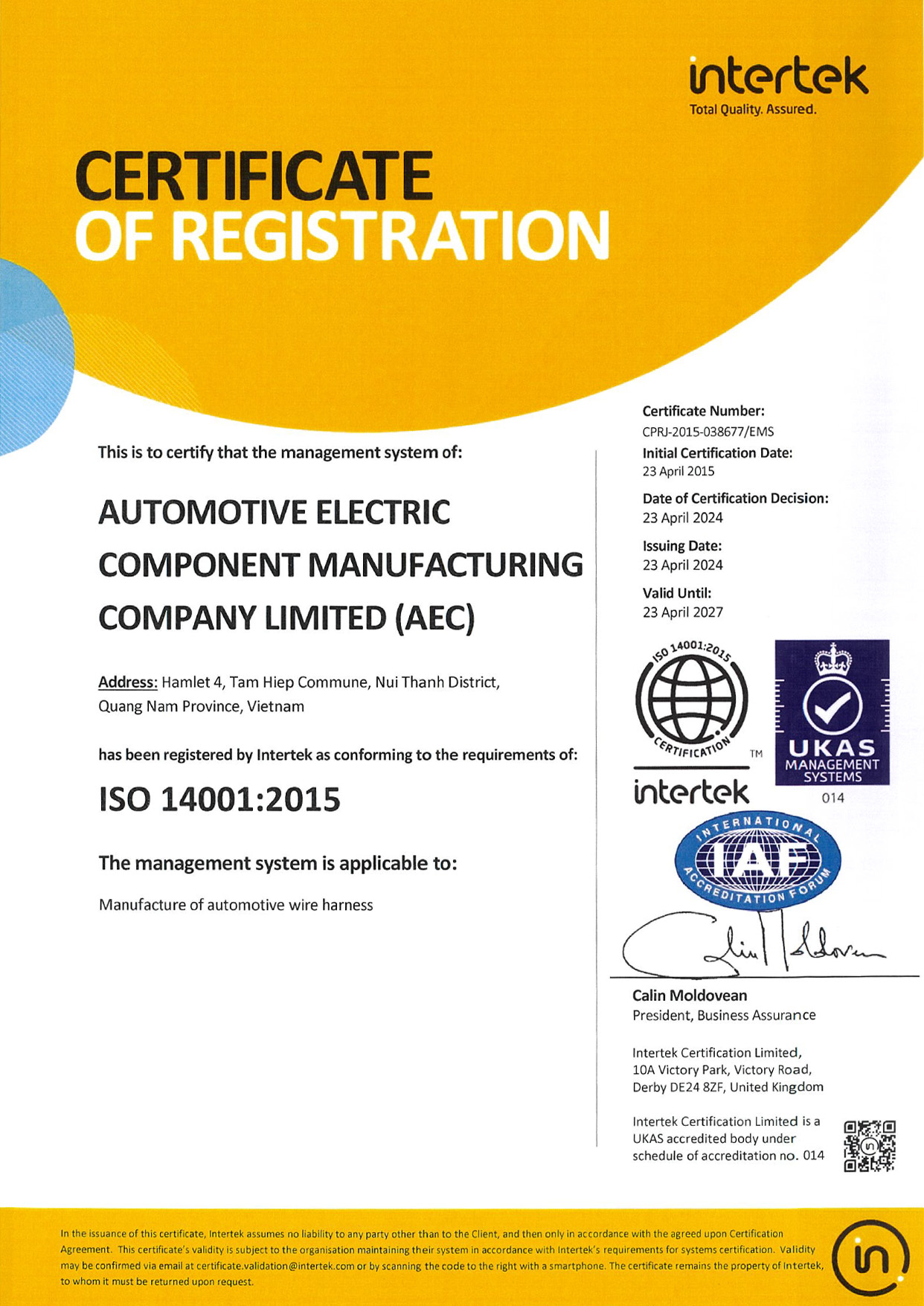

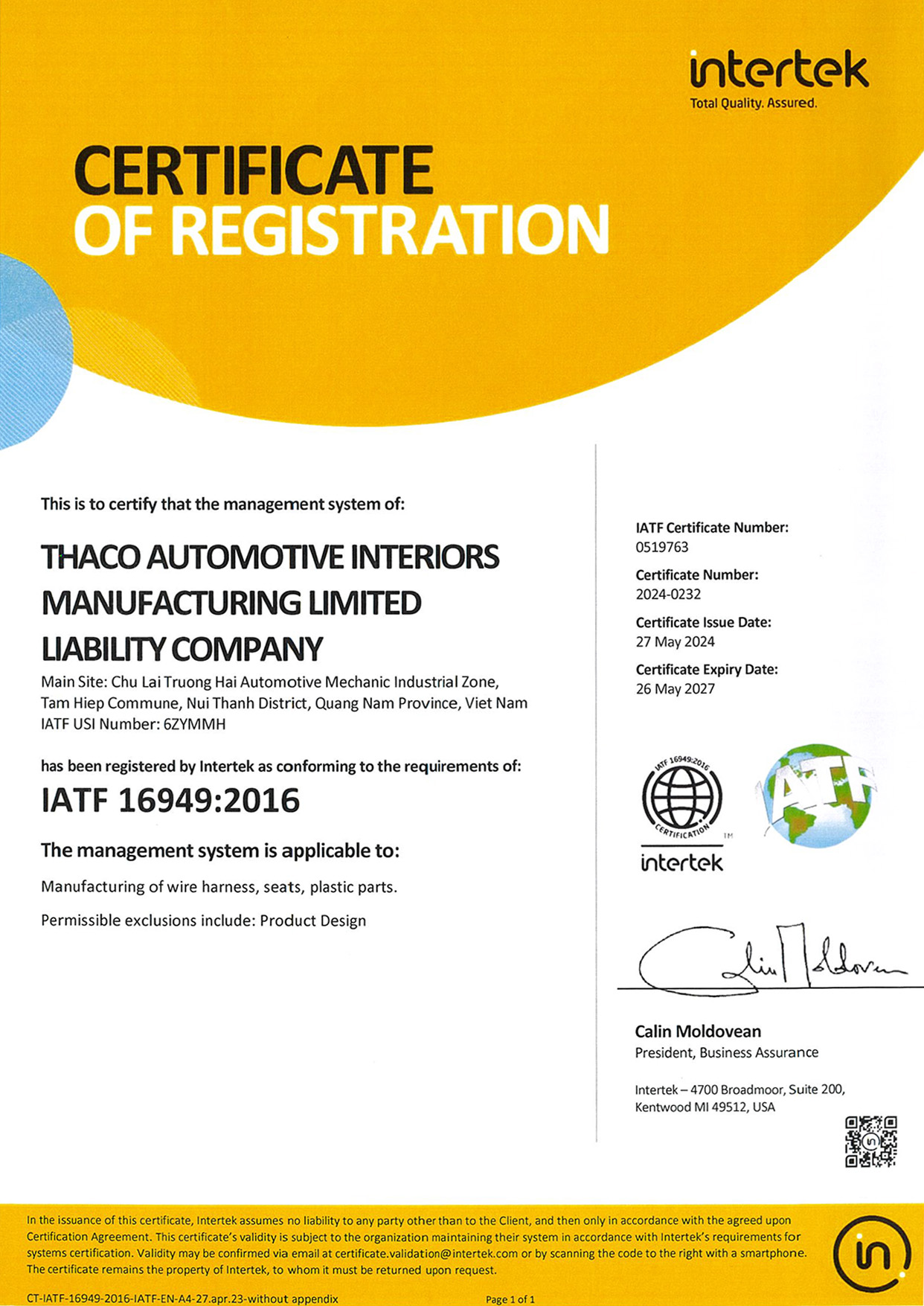

CERTIFICATES

THACO INDUSTRIES has obtained certification of the Quality Management System IATF 16949:2016, ISO 9001:2015, and the Environmental Management System ISO 14001:2015. Additionally, its products undergo strict quality control from input to output, adhering to Hyundai-Kia Motors Corporation standards.

PARTNERS

Markets

THACO INDUSTRIES serves global markets and supports OEM programs across North America (United States, Canada, Mexico) and Asia.

-

North America

-

Asia

FAQs

1. What information do you need to quote a custom wiring harness?

To provide an accurate quotation, we require technical drawings, a Bill of Materials (BOM), specifications, and expected order volume.

2. What wiring harness types and sizes do you manufacture?

We manufacture harnesses in multiple sizes and configurations for passenger cars, buses, trucks, electric bicycles, household wiring harnesses, and specialty equipment.

3. What is your typical lead time?

Prototype lead time depends on wiring harness complexity. Production lead times are set at order confirmation and aligned with customer delivery schedules.

4. What’s your MOQ?

Minimum order quantities are confirmed project-by-project, depending on materials and tooling requirements.

5. Are there tooling or engineering setup costs?

Yes. Tooling and engineering setup costs apply to new designs, but these can be spread across volumes to reduce unit pricing.