AUTOMOTIVE COMPONENT MANUFACTURER

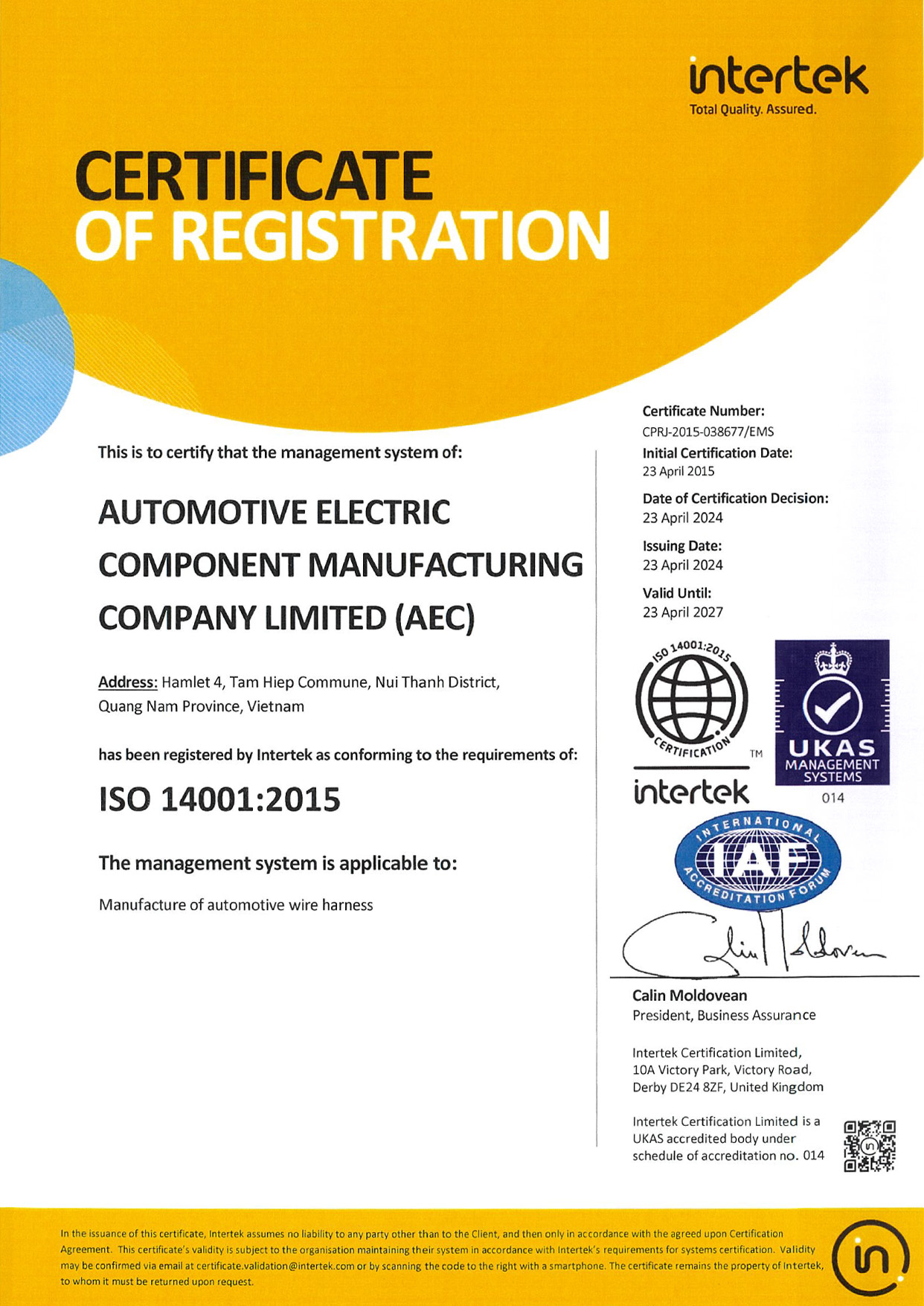

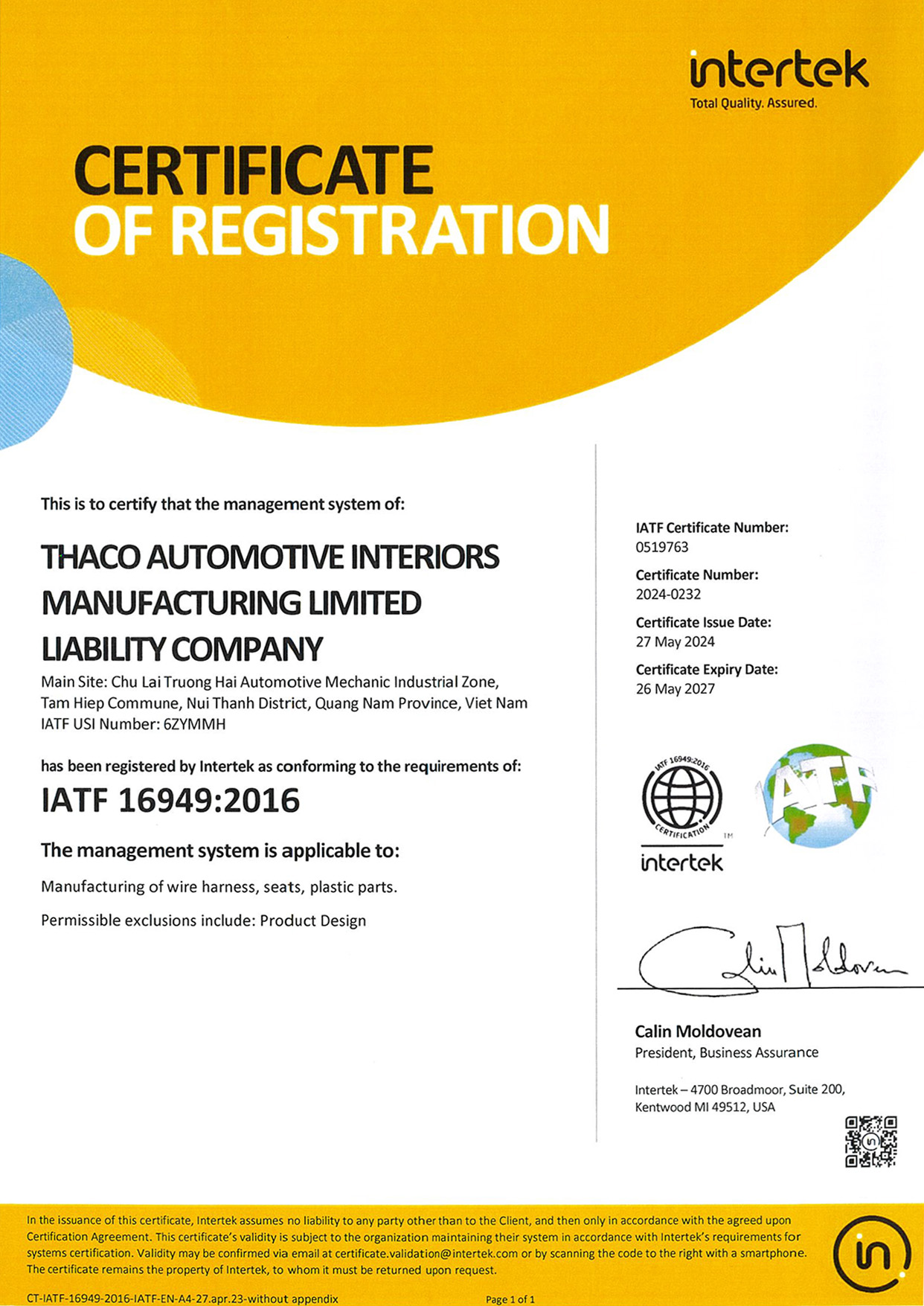

As a leading automotive component manufacturer in Vietnam, THACO INDUSTRIES leverages a 440,000 m², USD 500 million total investment in a complex of automotive component manufacturing plants to meet global manufacturing requirements. The corporation applies IATF 16949:2016, ISO 9001:2015 and ISO 14001:2015, reinforcing its commitment to international standards and strengthening its position as a trusted strategic partner for leading global automotive manufacturers.

Automotive Mechanical Components Manufacturing

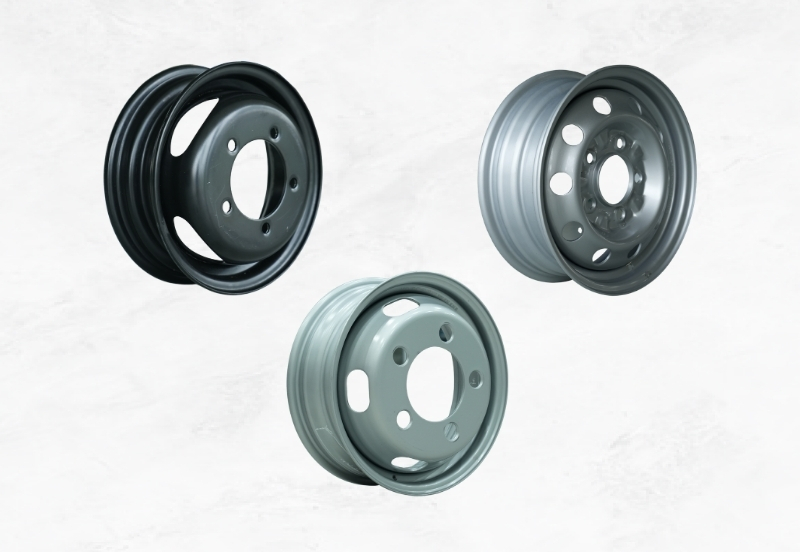

Wheel Rims Manufacturing

Passenger Car Seat Manufacturing

Automotive Electrical Equipment Manufacturing

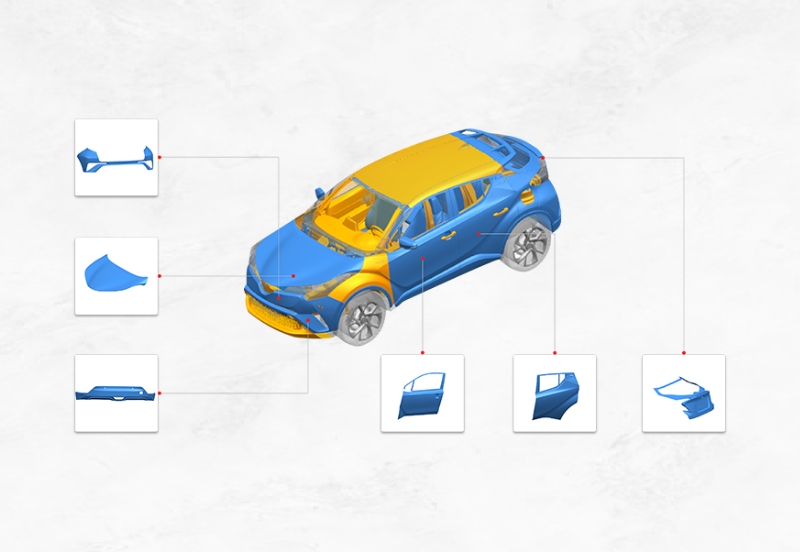

Plastic Components Manufacturing

Heat Press Components Manufacturing

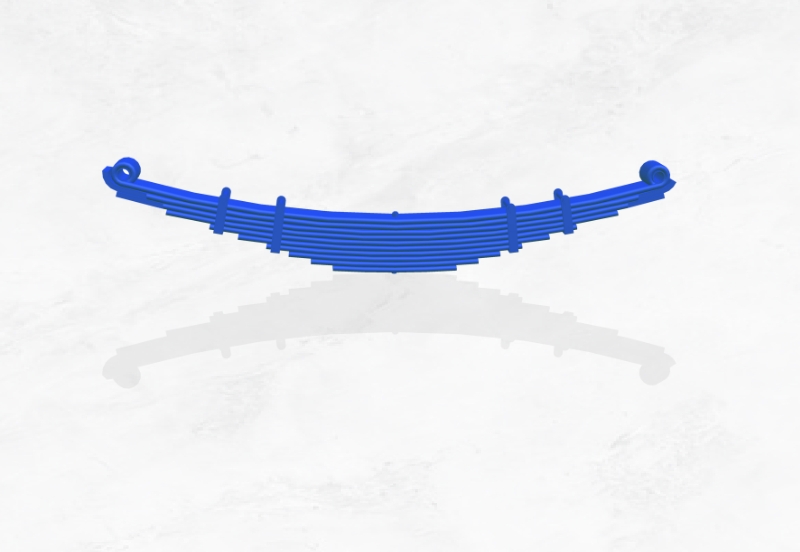

Leaf Spring Manufacturing

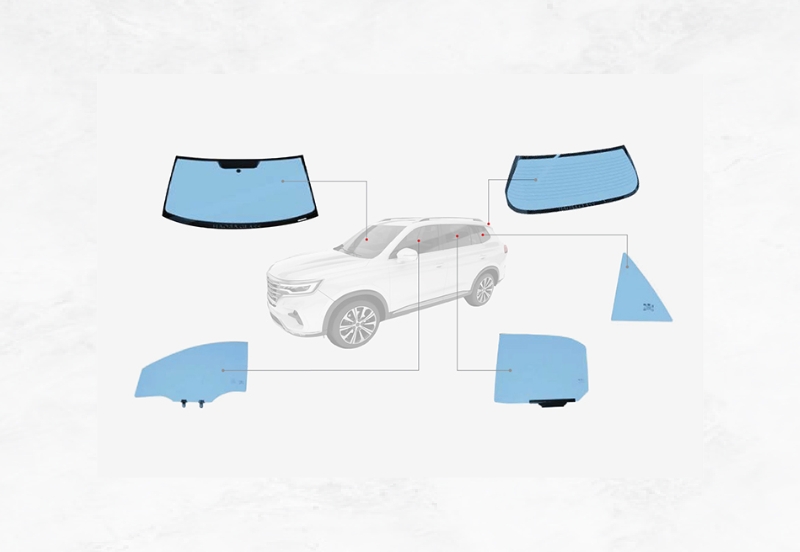

Automotive Glass Manufacturing

PRODUCTION TECHNOLOGY

Laser Cutting Machines

Robotic Welding Lines

Surface Treatment Painting Technology

ED coating and zinc-electroplating lines provide controlled film thickness and corrosion resistance for frames, brackets and mechanical parts.

Powder booths and wet-paint lines (water-based, PU, NC, oil) deliver specified thickness, gloss and adhesion for semi-trailer, truck and component surfaces.

Automotive Glass Tempering & Lamination Lines

Headliner Wet Type Production Line

Heat Treatment

Combined Stamping Machine

Plastic Injection Molding Line

3-sided Conveyor for Wiring Harness Assembly

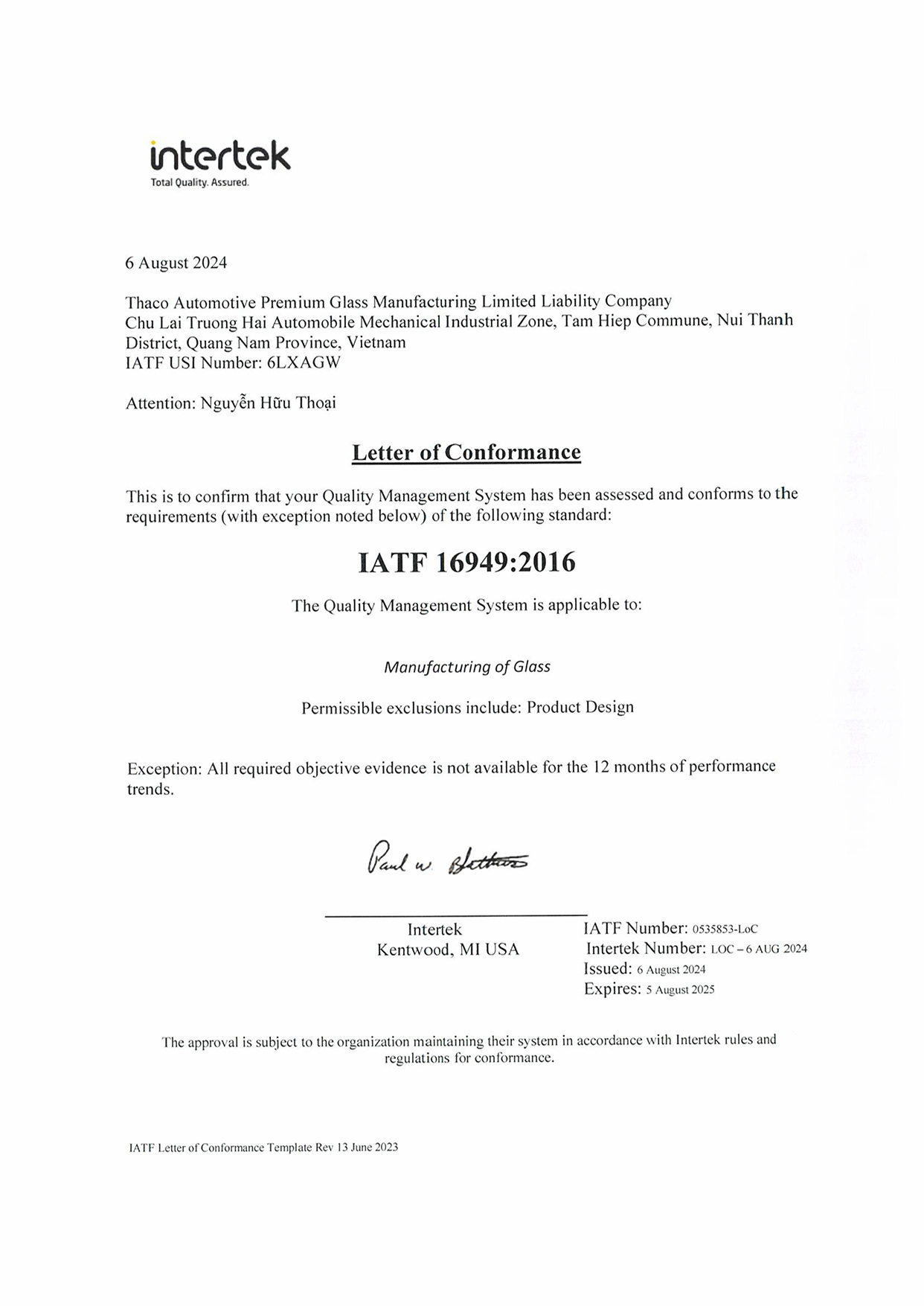

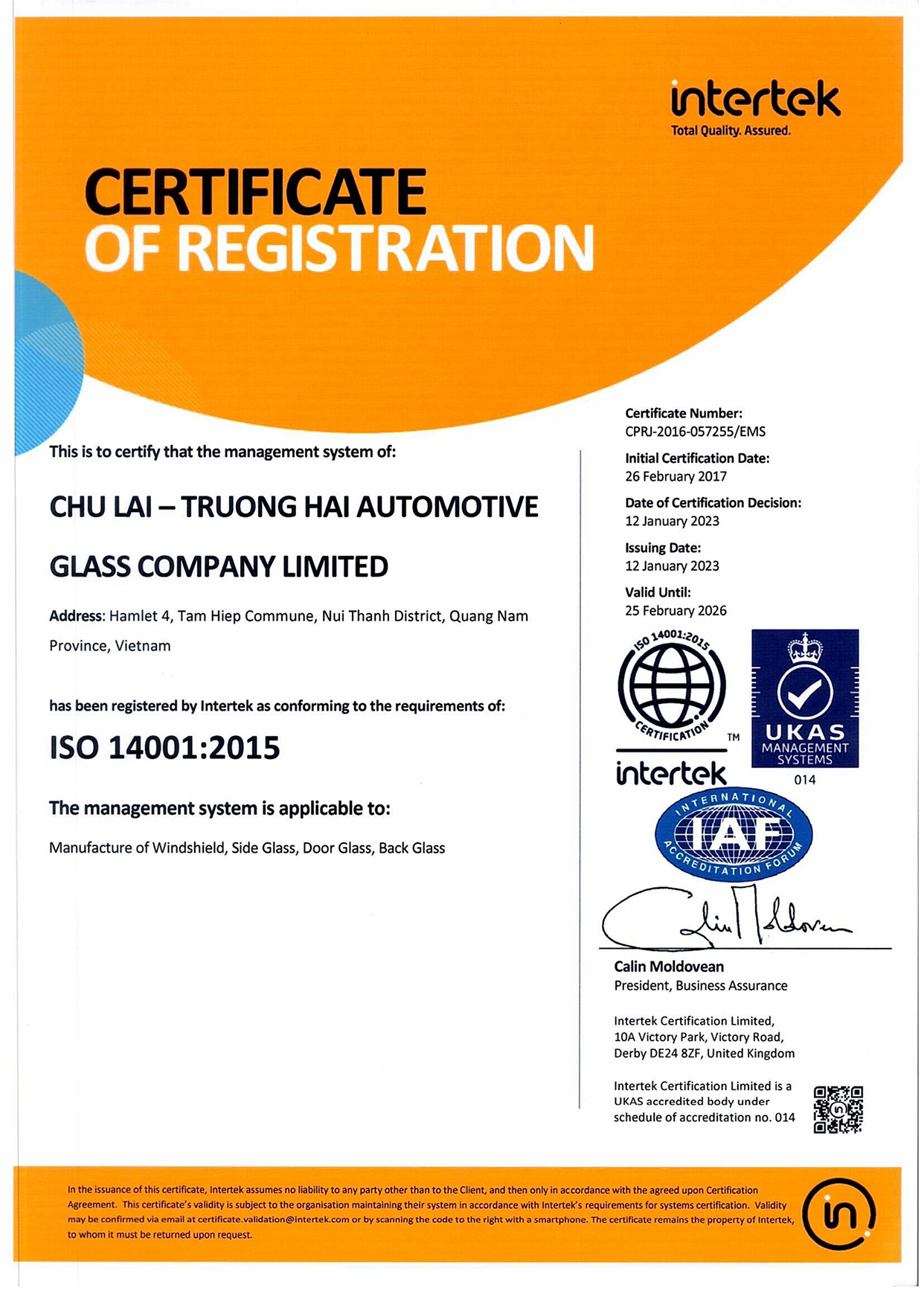

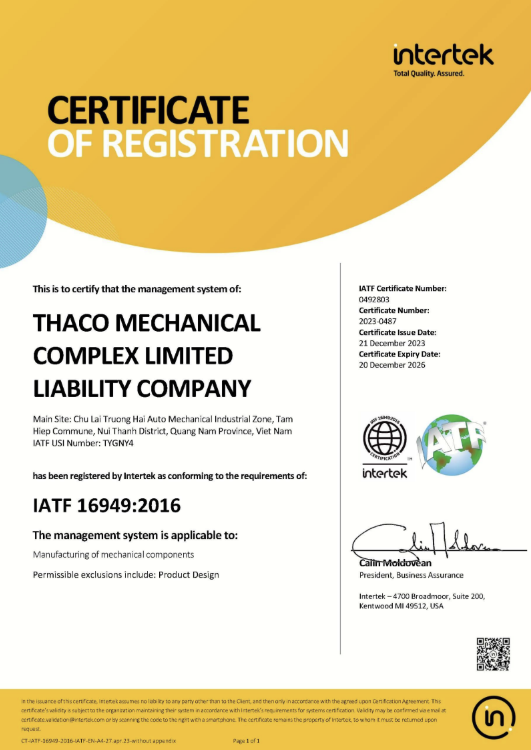

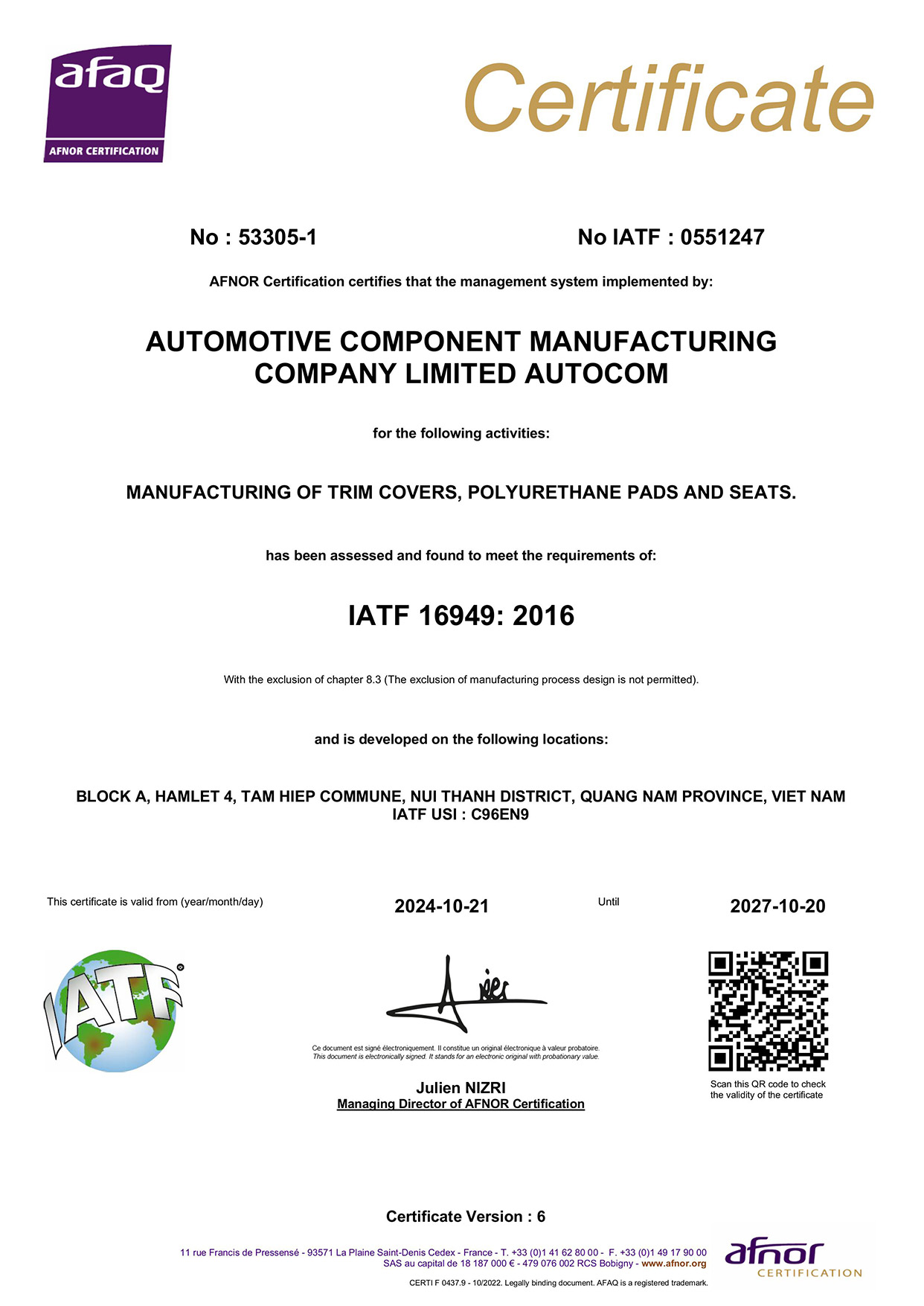

CERTIFICATIONS

THACO INDUSTRIES strictly complies with international standards in the production of automotive parts and components

OUR MARKETS

OUR PARTNERS

FAQs

What quality standards and certifications should an automotive manufacturer have?

Can THACO INDUSTRIES export automotive components to strict markets like the EU, Asia, and North America?

What components does THACO INDUSTRIES actually manufacture for OEMs?

What advantages does THACO INDUSTRIES offer compared to other component suppliers?

WHY PARTNER WITH THACO INDUSTRIES?

As a trusted OEM/ODM partner, THACO INDUSTRIES delivers end-to-end advantages across the automotive components. Backed by a state-of-the-art R&D center and an integrated manufacturing campus, we provide a fully connected value chain under one roof – from advanced machining and plastic injection molding to coating, assembly, and shipment.

Certified to IATF 16949:2016, ISO 9001:2015, and ISO 14001:2015, we ensure consistent quality, audit readiness, and full compliance with global standards. With proven experience supplying major brands and exporting to North America, Europe, and Asia, we help OEMs eliminate fragmented supplier networks, quality inconsistency, tooling delays, and supply-chain risks.

By partnering with THACO INDUSTRIES, customers benefit from faster time-to-market, reliable product durability, and a single point of accountability – from prototyping to long-term production. More than a manufacturer, we take ownership of the entire process, ensure full traceability, safeguard intellectual property, and scale alongside our partners’ growth – allowing them to focus on their core business.