PREMIUM AUTOMOTIVE GLASS COMPANY

Premium Automotive Glass Manufacturing Company is a specialised manufacturer of automotive glass, producing high-quality glass for passenger cars, trucks, and buses. The company complies with the National Technical Regulation on automotive safety glass as well as European durability standards, ensuring reliability for OEM applications.

Established in 2023, the company operates on a 60,000 m² site with a total investment of $55 million and an annual production capacity of 450,000 units. Its automotive glass products are supplied to major automotive manufacturers in Vietnam, including THACO Bus, THACO Truck, Kia, and Hyundai.

In addition to investing in modern technology, the company continuously enhances R&D capabilities to become Vietnam’s leading OEM automotive glass manufacturer and supplier.

Established in 2023, the company operates on a 60,000 m² site with a total investment of $55 million and an annual production capacity of 450,000 units. Its automotive glass products are supplied to major automotive manufacturers in Vietnam, including THACO Bus, THACO Truck, Kia, and Hyundai.

In addition to investing in modern technology, the company continuously enhances R&D capabilities to become Vietnam’s leading OEM automotive glass manufacturer and supplier.

2023

Establishment year

55 million USD

Investment

450,000 sets/year

Capacity

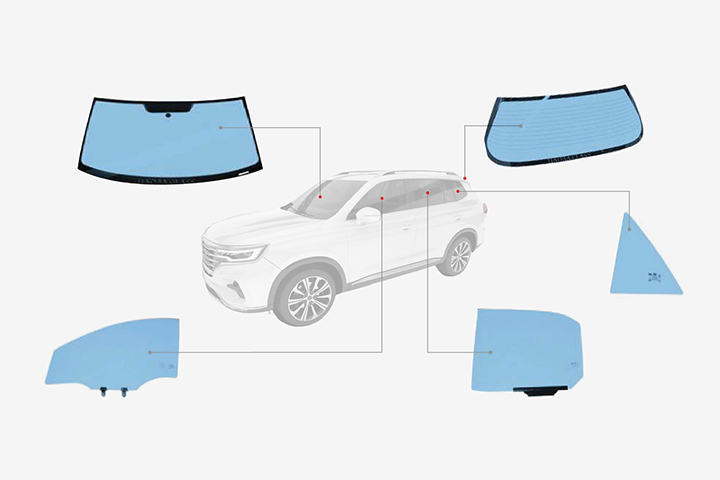

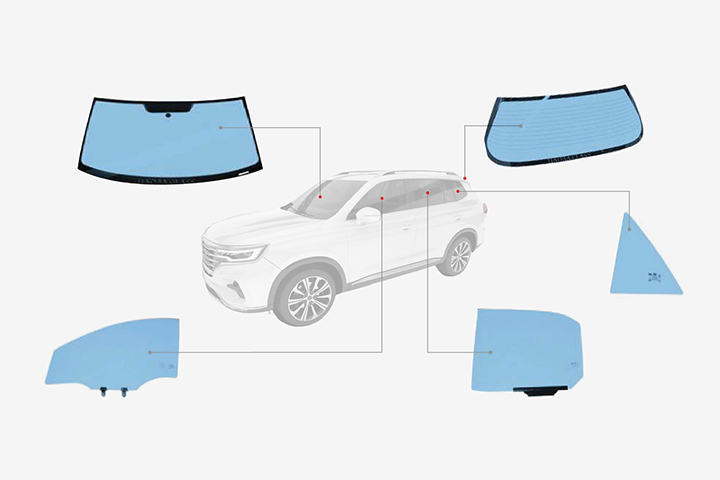

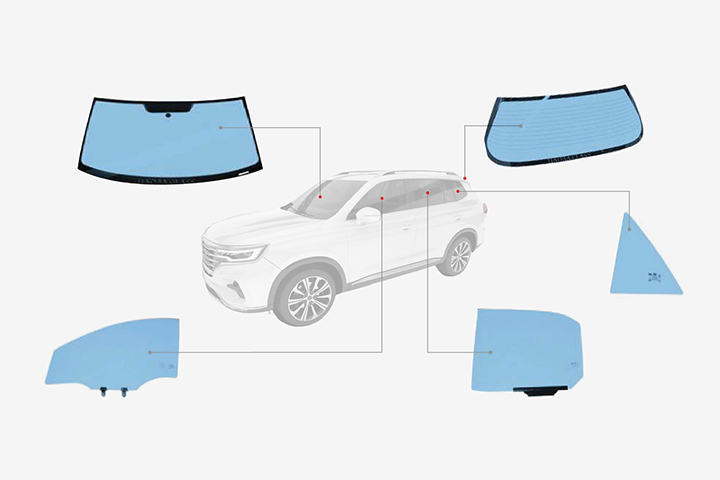

PRODUCTS

Door Glass - Passenger Car

Characteristics:

Tempered glass, 2 layers Laminated Glass

Color: White, green, black

Production Capability:

Max dimension: 600 × 1,200 mm

Min dimension: 400 × 500 mm

Thickness: 2.8 – 4.0 mm

Tempered glass, 2 layers Laminated Glass

Color: White, green, black

Production Capability:

Max dimension: 600 × 1,200 mm

Min dimension: 400 × 500 mm

Thickness: 2.8 – 4.0 mm

Backlite Glass - Passenger Car

Characteristics:

Tempered glass; optional heated wire & water-repellent glass

Color: White, green, black

Production Capability:

Max dimension: 600 – 1,500 mm

Min dimension: 100 – 300 mm

Thickness: 2.85 – 4.0 mm

Tempered glass; optional heated wire & water-repellent glass

Color: White, green, black

Production Capability:

Max dimension: 600 – 1,500 mm

Min dimension: 100 – 300 mm

Thickness: 2.85 – 4.0 mm

Windshield Glass - Passenger Car

Characteristics:

Laminated safety glass (2 layers): optional Standard, HUD, water-repellent, heated-wire

Color: White, green

Production Capability:

Max dimension: 1,700 × 1,250 mm

Min dimension: 900 × 500 mm

Thickness: 4.0 – 5.36 mm

Laminated safety glass (2 layers): optional Standard, HUD, water-repellent, heated-wire

Color: White, green

Production Capability:

Max dimension: 1,700 × 1,250 mm

Min dimension: 900 × 500 mm

Thickness: 4.0 – 5.36 mm

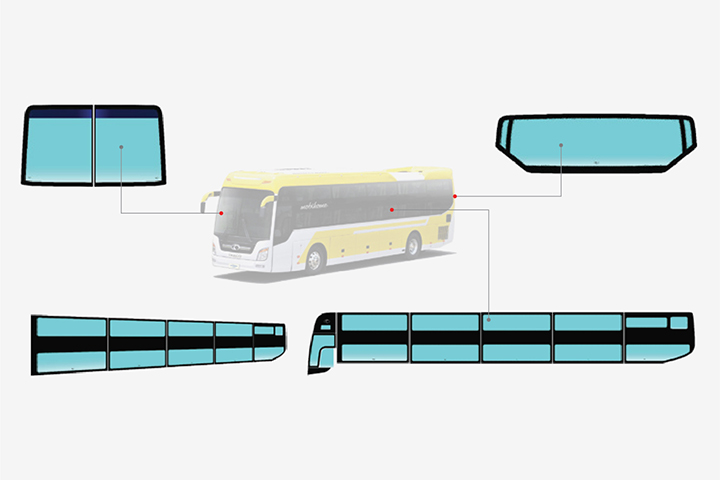

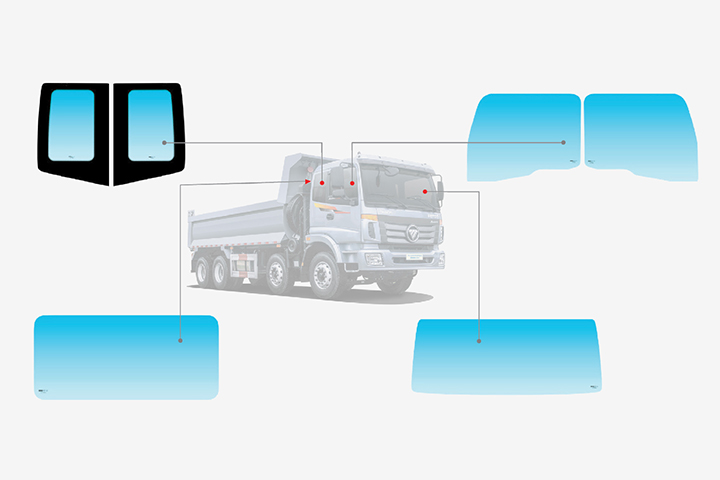

Tempered Glass - Bus & Truck

Characteristics:

Tempered glass

Color: White, green

Production Capability:

Max dimension: 2,200 × 1,500 mm

Min dimension: 100 × 300 mm

Thickness: 3.5 – 6.0 mm

Tempered glass

Color: White, green

Production Capability:

Max dimension: 2,200 × 1,500 mm

Min dimension: 100 × 300 mm

Thickness: 3.5 – 6.0 mm

Laminated Glass - Bus & Truck

Characteristics:

2-layer laminated glass

Color: White, green

Production Capability:

Max dimension: 2,000 × 3,000 mm

Min dimension: 100 × 100 mm

Thickness: 4.76 – 9.76 mm

2-layer laminated glass

Color: White, green

Production Capability:

Max dimension: 2,000 × 3,000 mm

Min dimension: 100 × 100 mm

Thickness: 4.76 – 9.76 mm

PRODUCTION PROCESS

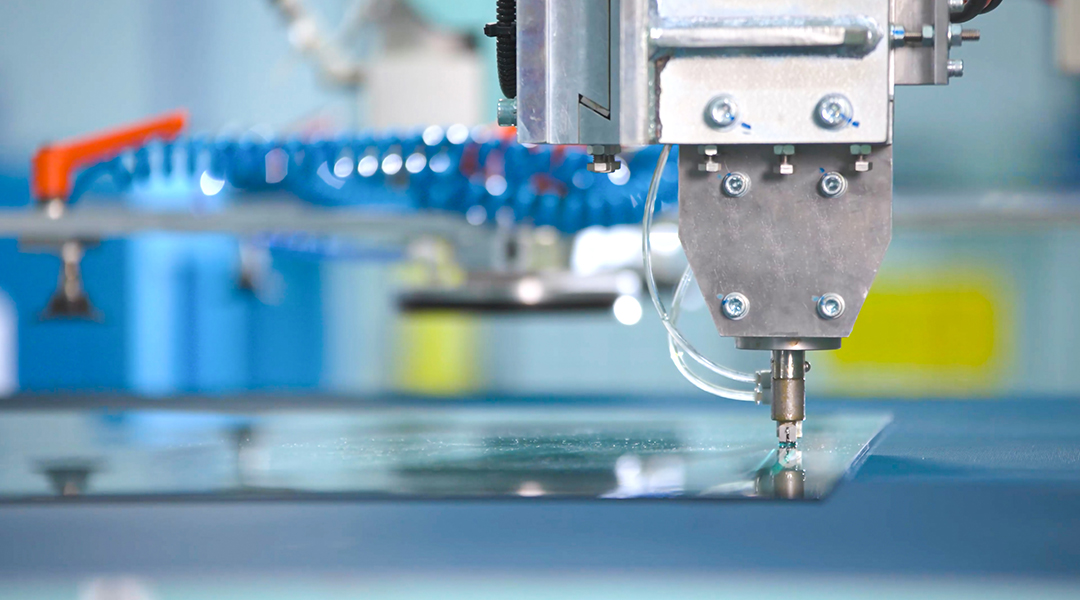

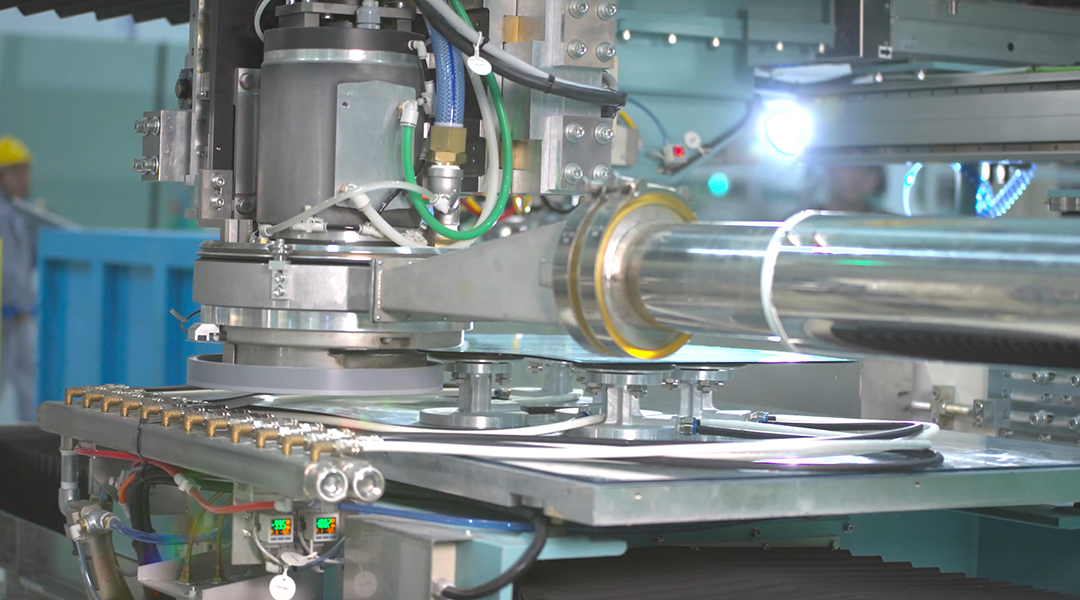

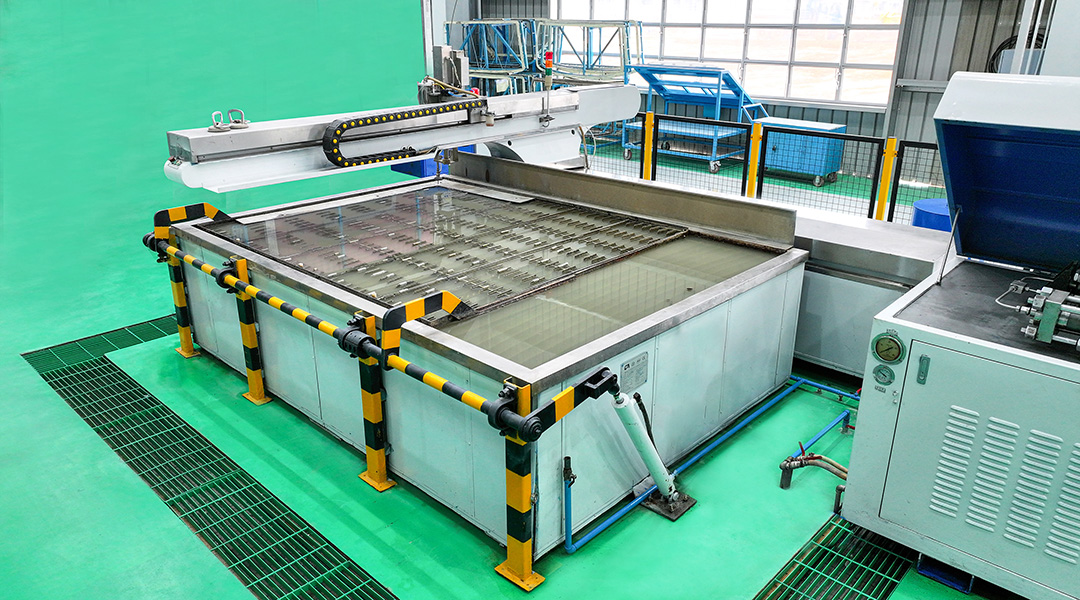

Pre-processing stage

Includes steps: cutting, contour machining (cutting, grinding, drilling), washing, logo/silk screen printing.

The production line is equipped with modern machinery and equipment that are highly automated, such as:

- CNC cutting (CNC Cutting Machine): High-precision cutting, speed up to 130 m/set.

- Edge shaping & drilling (Cutting–Grinding–Drilling Line): Shapes outlines, holes; capacity 1,000 pcs/8h; max size 1,850×1,250 mm.

- Glass washing (Flat & Curved Washing Machines): Flat washing for general products; curved washing for windshield lamination.

- Printing (Silk Screen / Heating Grid / Logo Printing): Black silk screen printing for mask borders, heating silk screen for defroster grids, logo printing room for marking

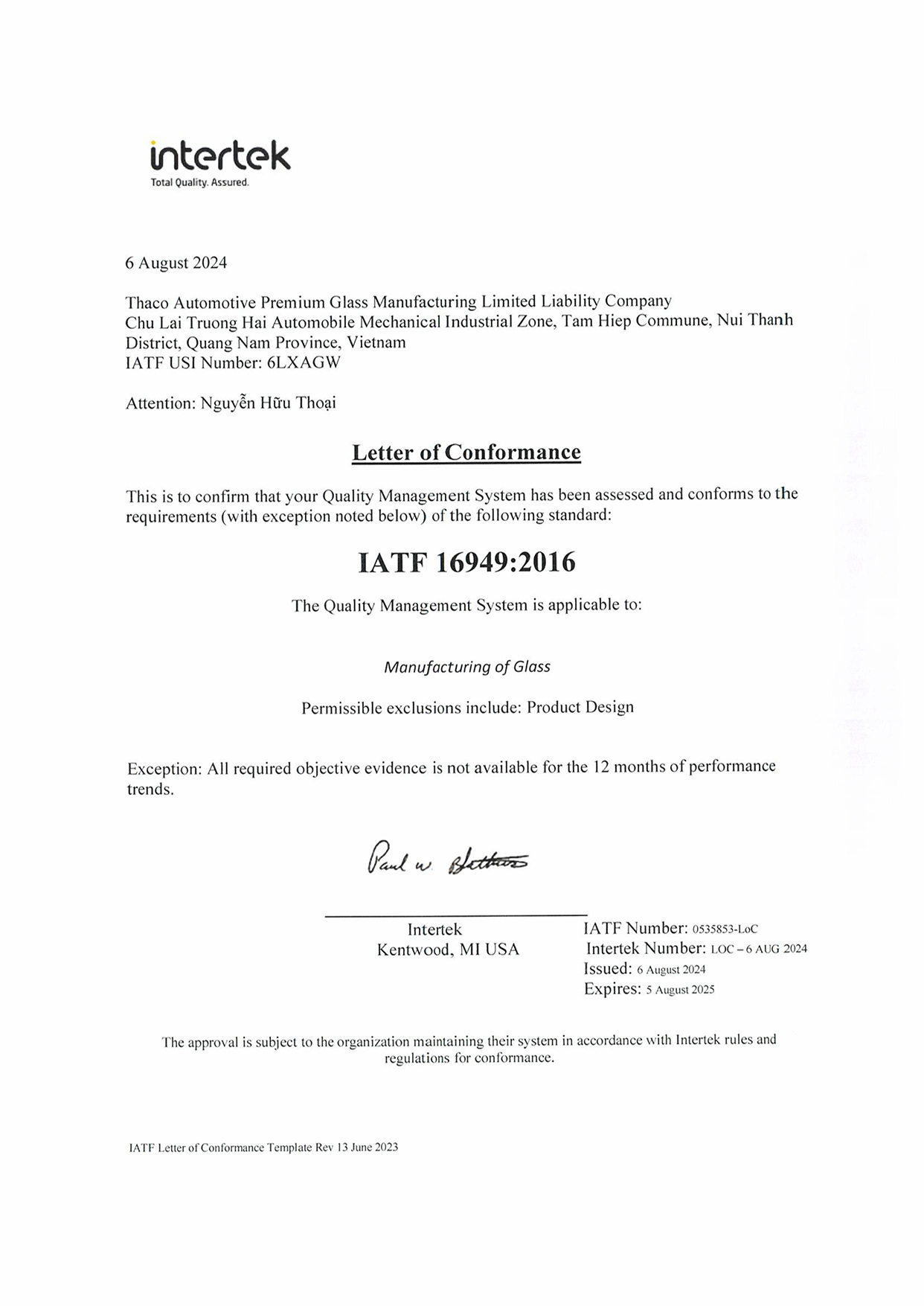

CERTIFICATES

Premium Automotive Glass Manufacturing Company has obtained certification of the Quality Management System ISO 9001:2015 and the Environmental Management System ISO 14001:2015, IATF 16949:2016. The products meet the ECE R43 standard of European standards.

PARTNERS

MARKETS

Premium Automotive Glass Manufacturing Company is trusted by leading automotive brands, including KIA, Hyundai, Isuzu, and other major OEM partners. With proven manufacturing capability and strict compliance with international standards, the company is steadily advancing its goal of becoming the leading OEM automotive glass manufacturer in Vietnam and the wider region.

FAQs

What types of automotive glass does THACO INDUSTRIES manufacture?

THACO INDUSTRIES owns a Premium automotive glass manufacturing company. We produce and supply glass for passenger cars, trucks, and buses. For passenger cars, the portfolio includes windshields, back glass, front-door glass, rear-door glass, and quarter glass. For trucks and buses, the company supplies windshields, door glass, cabin window glass, side-fixed glass (LH/RH), and back glass.

What is THACO INDUSTRIES' production capacity?

Premium Automotive Glass Manufacturing Company has an annual production capacity of 450,000 sets of automotive glass, covering passenger cars, trucks, and buses.

How does THACO INDUSTRIES manage lead time?

Lead time is planned based on OEM and Tier-1 schedules, order volume, and project scope, and is aligned with THACO INDUSTRIES’ end-to-end OEM manufacturing and logistics model (design-production-testing-logistics) as well as standard Incoterms® 2020 practices used across its car-parts supply.

Specific lead times are confirmed case-by-case during the RFQ and contract process.

Can you supply OEM-grade automotive glass for vehicle manufacturers?

Yes. Automotive glass is part of THACO INDUSTRIES’ OEM automotive components portfolio, which also includes springs, wiring harnesses, air-conditioners, condensers, and interior/exterior parts.

What quality control systems are implemented during manufacturing?

Quality is managed through a combination of certified management systems (IATF 16949, ISO 9001, ISO 14001) and automotive quality tools such as PPAP, FAI, Control Plan, and PFMEA, which THACO INDUSTRIES applies to its car-parts manufacturing operations.

For automotive glass specifically, products are designed and tested to comply with ECE R43 and undergo checks for optical distortion, fragmentation behavior, and environmental resistance.