Product information

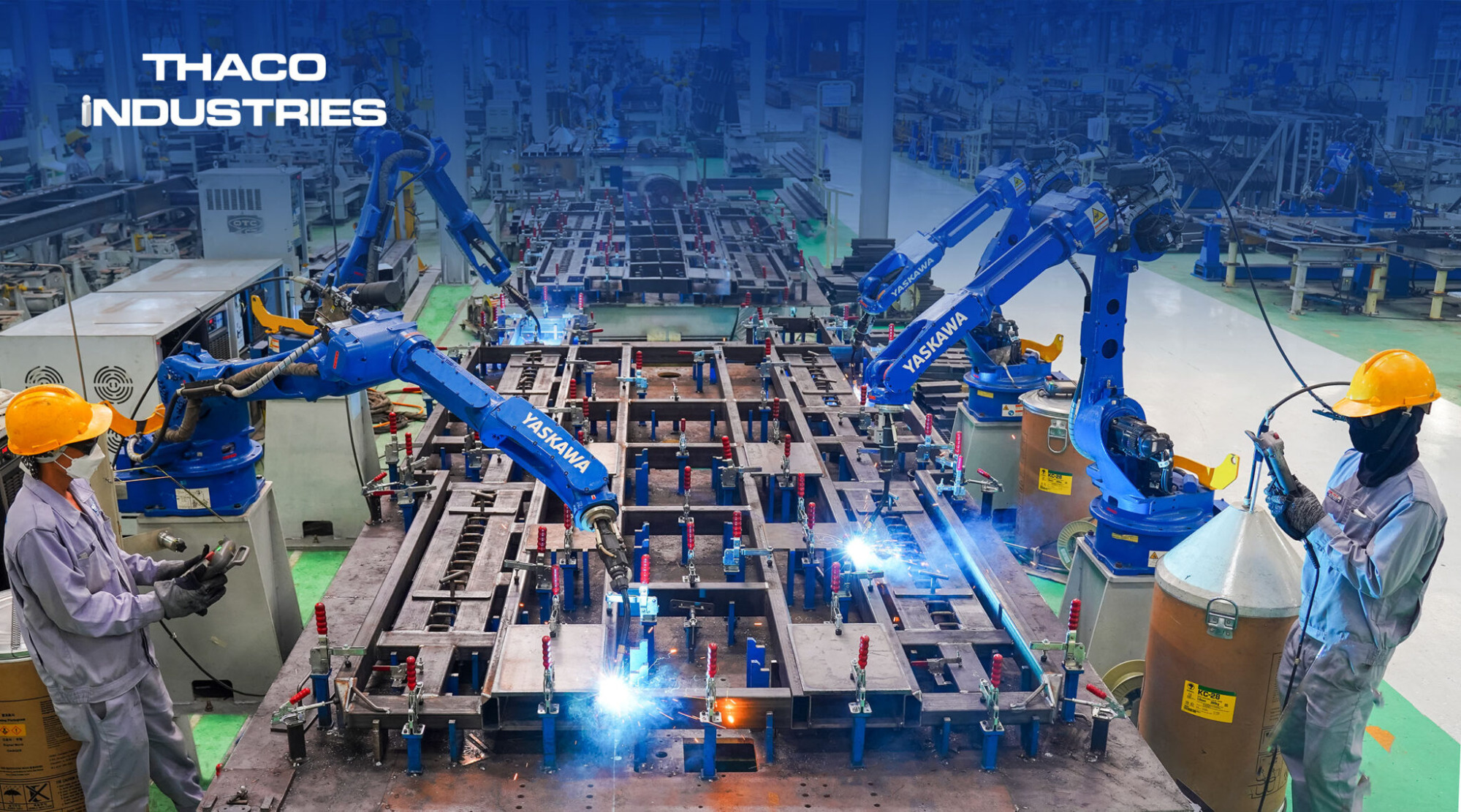

Robotic Welding Services: Enhancing Precision and Efficiency

Robotic welding services are reshaping modern metal fabrication by ensuring consistent weld quality, faster production cycles, and improved workplace safety. Through programmable robotics and precise motion control, it delivers accuracy and repeatability that manual welding cannot achieve. In the article below, THACO INDUSTRIES explores how robotic welding technology enhances manufacturing performance and meets the demanding standards of the European market.

Introduction to Robotic Welding Services

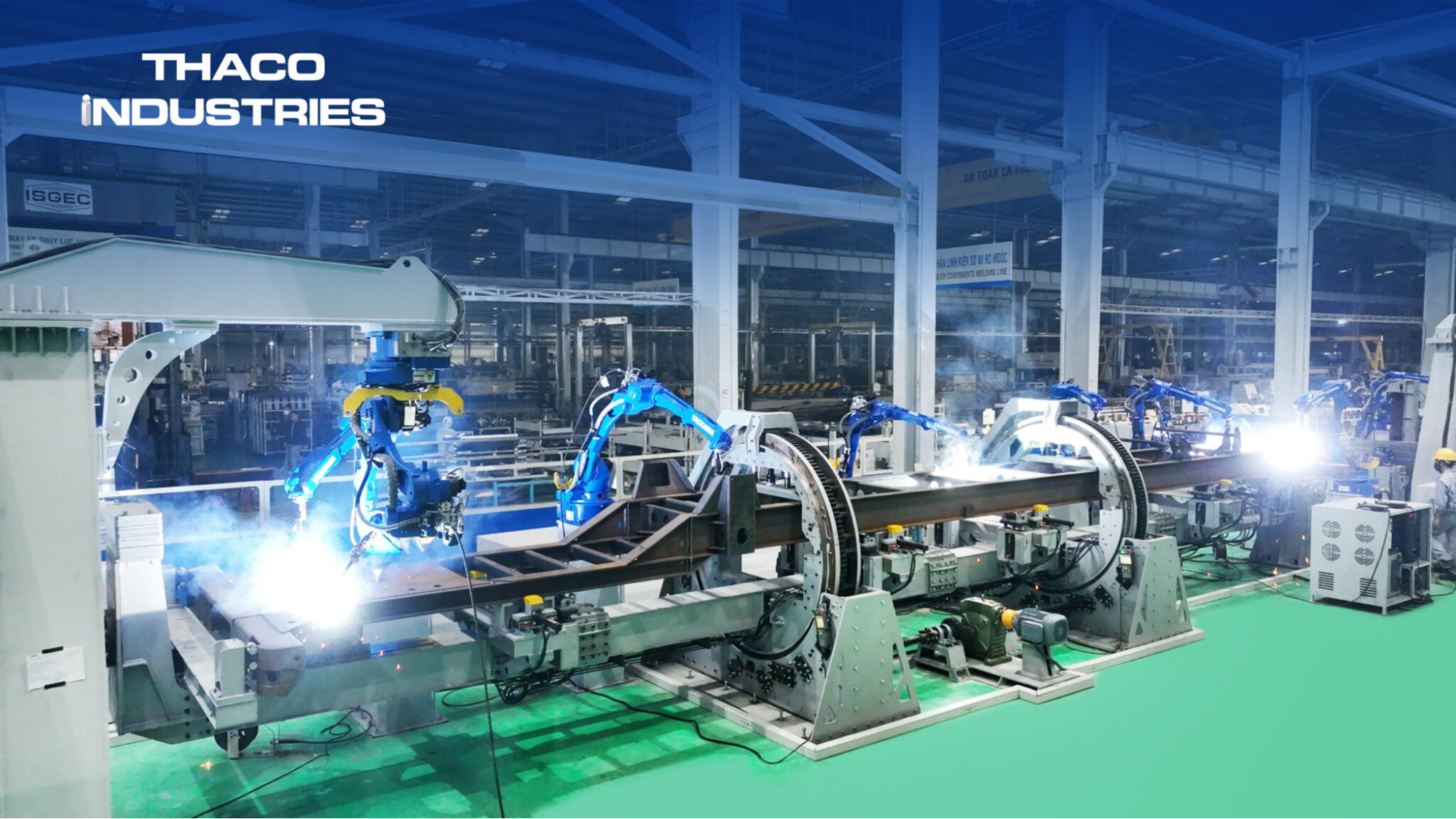

Robotic welding services utilize programmable automation systems to execute welding operations with exceptional consistency and precision across high-volume production environments. Manufacturing facilities implementing automated welding achieve significant improvements in cycle time reduction, dimensional accuracy, and weld integrity compared to traditional manual processes. The integration of six-axis articulated robots with advanced welding controllers enables manufacturers to maintain strict tolerances while minimizing material waste and rework costs.

Automated welding operations surpass manual techniques through measurable performance advantages. Speed improvements of 40-60% result from continuous robot operation without fatigue-related slowdowns. Repeatability ensures identical weld profiles across thousands of components, eliminating the dimensional variation inherent in human-performed tasks. Error reduction occurs through programmed parameter control, preventing common mistakes like improper travel speed or inconsistent torch angle. Safety enhancements protect workers from direct exposure to welding radiation, fumes, and molten metal hazards.

Modern robotic welding workflows follow a structured sequence that ensures quality from design through delivery. Initial design validation confirms weld joint accessibility and fixture requirements. Offline robot path programming creates optimized motion trajectories without disrupting production. Automated weld execution maintains consistent parameters across every cycle. Multi-point quality verification employs visual inspection, dimensional measurement, and non-destructive testing. Final surface finishing operations prepare components for coating or assembly integration.

View more: Kitting and Assembly Services for Efficient Production

Key Types of Robotic Welding

Selecting the appropriate welding technology depends on material specifications, joint configurations, and production throughput requirements. Each robotic welding method offers distinct capabilities suited to specific manufacturing scenarios, with selection criteria including base metal composition, thickness range, desired penetration depth, and acceptable heat input levels.

MIG/MAG Robotic Welding

Metal Inert Gas and Metal Active Gas welding processes deliver high deposition rates suitable for both thin-gauge sheet metal and structural steel components. Automated MIG/MAG systems maintain consistent wire feed speeds and shielding gas flow, producing uniform weld beads across extended production runs. This technology excels in applications requiring rapid cycle times, particularly for carbon steel and low-alloy materials in thickness ranges from 0.8mm to 12mm. Manufacturing operations benefit from MIG/MAG robotics when producing frames, brackets, enclosures, and structural assemblies where speed and penetration depth take priority over cosmetic finish requirements.

TIG Robotic Welding

Tungsten Inert Gas welding provides superior control for precision applications involving stainless steel alloys, aluminum, and titanium components. The non-consumable electrode configuration enables clean, spatter-free joints with minimal heat-affected zones. Robotic TIG systems prove essential for industries demanding exceptional weld aesthetics and metallurgical integrity.

The technology handles specialized applications where weld purity and mechanical properties cannot tolerate contamination or excessive thermal distortion:

- Thin-Wall Tubing: Precision joining of pharmaceutical, food processing, and semiconductor industry piping systems.

- Critical Pressure Boundaries: Leak-tight joints in vacuum chambers, heat exchangers, and pressure vessels.

- Corrosion-Resistant Assemblies: Stainless steel structures for chemical processing, marine environments, and medical equipment.

- Aerospace Components: Titanium and aluminum assemblies requiring verified weld procedures and complete traceability documentation.

Spot Welding

Resistance spot welding robots dominate automotive body assembly lines, joining overlapping sheet metal panels through localized heat generation and pressure application. Multi-gun robotic cells complete hundreds of spot welds per vehicle body, ensuring structural rigidity and crashworthiness. The technology adapts effectively to coated steels, galvanized materials, and mixed-thickness configurations common in transportation manufacturing. Spot welding systems achieve cycle times measured in seconds per joint, making them ideal for high-volume production environments requiring thousands of identical assemblies daily.

View more: Sheet Metal Fabrication: Complete Guide for B2B Clients

Advantages of Robotic Welding Services

Implementing robotic welding services transforms manufacturing operations through quantifiable improvements in quality consistency, production velocity, worker protection, and long-term cost structure. These advantages compound across extended production runs, delivering competitive differentiation in markets demanding both precision and volume capability.

Automated welding systems eliminate human variability, producing identical weld profiles across thousands of components with measurable defect rate reductions. Statistical process control integrated with robotic cells, as applied in THACO INDUSTRIES’s mechanical processing, enables real-time monitoring of welding parameters and ensures consistent compliance with technical specifications. Dimensional consistency ensures assemblies meet tolerance requirements without manual rework or scrap generation.

Production throughput increases by 50-80% compared to manual operations, as robots maintain continuous operation across multiple shifts without fatigue-related quality degradation. Changeover time between product variants decreases through stored programs that recall exact welding sequences and parameters. Material utilization improves through precise wire feed control and optimized travel paths that minimize consumable waste.

Operator safety improves substantially when personnel transition from direct welding exposure to supervisory roles monitoring automated cells. Reduced contact with welding fumes, ultraviolet radiation, and molten metal splash lowers workplace injury rates and long-term health risks. Ergonomic benefits eliminate repetitive strain injuries associated with manual torch manipulation and awkward working positions.

The economic benefits compound over extended production horizons, where initial automation investment costs are distributed across millions of welded joints, yielding lower per-unit manufacturing expenses. Labor cost stability insulates manufacturers from wage fluctuations and workforce availability constraints. Quality-related savings accumulate through reduced warranty claims, field failures, and customer returns attributable to weld defects.

Complex three-dimensional geometries and multi-axis weld paths that challenge manual welders become routine for robotic systems equipped with collision avoidance algorithms and adaptive seam tracking. High-volume assembly operations requiring thousands of identical components per week achieve the consistency necessary for statistical quality assurance and regulatory compliance documentation.

Applications Across Industries

Robotic welding services support critical fabrication requirements across multiple industrial sectors, each with distinct technical specifications and regulatory compliance standards. Understanding application-specific demands enables manufacturers to optimize welding processes for material performance, production efficiency, and end-use reliability.

Automotive & Transportation

The automotive industry pioneered the widespread adoption of robotic welding and remains its largest consumer. Robotic welding services are integral to assembling vehicle chassis, structural frames, suspension components, exhaust systems, and fuel tanks. Modern automotive production lines deploy hundreds of welding robots working in synchronized sequences to build complete vehicle bodies with exceptional dimensional accuracy and structural integrity.

The industry’s demanding requirements for crash safety, corrosion resistance, and aesthetic quality drive continuous advancement in robotic welding technologies. From economy passenger vehicles to heavy commercial trucks, robotic welding ensures consistent quality across millions of units while meeting ever-stricter safety regulations and fuel efficiency standards.

Industrial Equipment & Machinery

Heavy equipment manufacturers utilize robotic welding services for construction machinery frames, hydraulic excavator booms, agricultural implement assemblies, and material handling equipment structures. The technology ensures consistent penetration depth and fusion quality in thick-section welds, critical for components experiencing high stress concentrations.

Modular machinery frames benefit from robotic welding’s repeatability, enabling manufacturers to maintain interchangeable subassemblies across product families. Mining equipment, forestry machinery, and industrial presses require welds capable of withstanding severe operational environments where joint failure results in costly downtime and safety hazards.

Energy & Utilities

Pipeline infrastructure, pressure vessel fabrication, offshore platform structures, and wind turbine tower sections require welding procedures validated to ASME, API, and ISO standards. Robotic welding services maintain certified weld procedure specifications across every joint, generating complete traceability records for regulatory audits.

Automated welding is increasingly adopted in the fabrication of solar mounting structures and electrical distribution equipment to improve consistency and production efficiency. At THACO INDUSTRIES, similar robotic welding technologies are integrated into industrial equipment manufacturing systems to support large-scale, high-volume production for renewable energy and infrastructure projects. Precision and repeatability prove essential for high-pressure containment applications where weld defects could result in catastrophic failures or environmental releases.

Selecting a Reliable Robotic Welding Partner

Choosing a manufacturing partner for robotic welding services requires a systematic evaluation of technical capability, quality management, production capacity, and engineering collaboration. Strategic partnerships with qualified fabricators ensure long-term supply chain stability and continuous improvement, reducing total cost of ownership while enhancing product quality and consistency.

Evaluation Criteria

When selecting a provider for robotic welding services, key areas to evaluate include:

- Technology and Equipment: Use of modern articulated robots from leading global brands, multi-process capabilities (MIG, TIG, and spot welding), and advanced offline programming systems that reduce setup time between production runs.

- Production Capacity: Verified utilization rates, redundancy to ensure production continuity, and scalability to meet customer demand fluctuations.

- Quality Assurance: Implementation of coordinate measuring machine (CMM) verification, non-destructive testing (NDT), and full material traceability.

- Certifications: Compliance with international standards such as ISO 9001:2015 and IATF 16949:2016 for automotive and industrial manufacturing.

Why Partner with THACO INDUSTRIES?

THACO INDUSTRIES operates one of Vietnam’s most advanced manufacturing complexes, featuring a welding line equipped with approximately 100 robotic welding stations integrated with laser cutting and automated material handling systems.

The corporation employs a team of R&D engineers and technical experts who utilize advanced 3D simulation and design software to customize designs, simulate weld paths, and optimize production processes.

Key advantages include:

- Comprehensive robotic welding services across MIG, TIG, and spot welding applications.

- Modern robotic infrastructure ensures high precision, speed, and repeatability.

- Strong engineering and R&D capability supporting customized product design and manufacturability optimization.

- High-volume production readiness, ensuring rapid response to large and urgent orders.

- Certified quality management system meeting global industrial and automotive standards.

- Commitment to scalability through continuous investment in equipment and workforce training.

Quality Assurance and Traceability

All welded assemblies undergo rigorous dimensional verification, visual inspection, and non-destructive testing such as ultrasonic or dye penetrant examination. Each component is traceable to its material source, welding parameters, operator certification, and inspection record, ensuring full transparency and quick corrective action if required.

Partner for Performance

Manufacturers seeking dependable robotic welding services should prioritize partners with proven technical expertise, production flexibility, and collaborative engineering support. THACO INDUSTRIES delivers end-to-end project management from design-for-manufacturability consultation to post-delivery technical support, ensuring seamless integration of welded components into final assemblies.

Contact THACO INDUSTRIES to schedule a technical consultation or submit a request for quotation (RFQ) with detailed drawings, material specifications, and volume requirements. Our engineering team will provide a tailored cost and capability assessment.

Email: partsales@thaco.com.vn

Hotline: +84 348 620 063