INDUSTRIAL EQUIPMENT MANUFACTURER

Mining & Construction Equipment Manufacturing

Across this mechanical complex, we deliver an annual capacity of 200,000 tons of steel and 300,000 mechanical products. This capacity supports high-volume, heavy-duty production of excavator buckets, grab bucket systems, crusher parts, conveyor structures, and electrical cabinet housing frames.

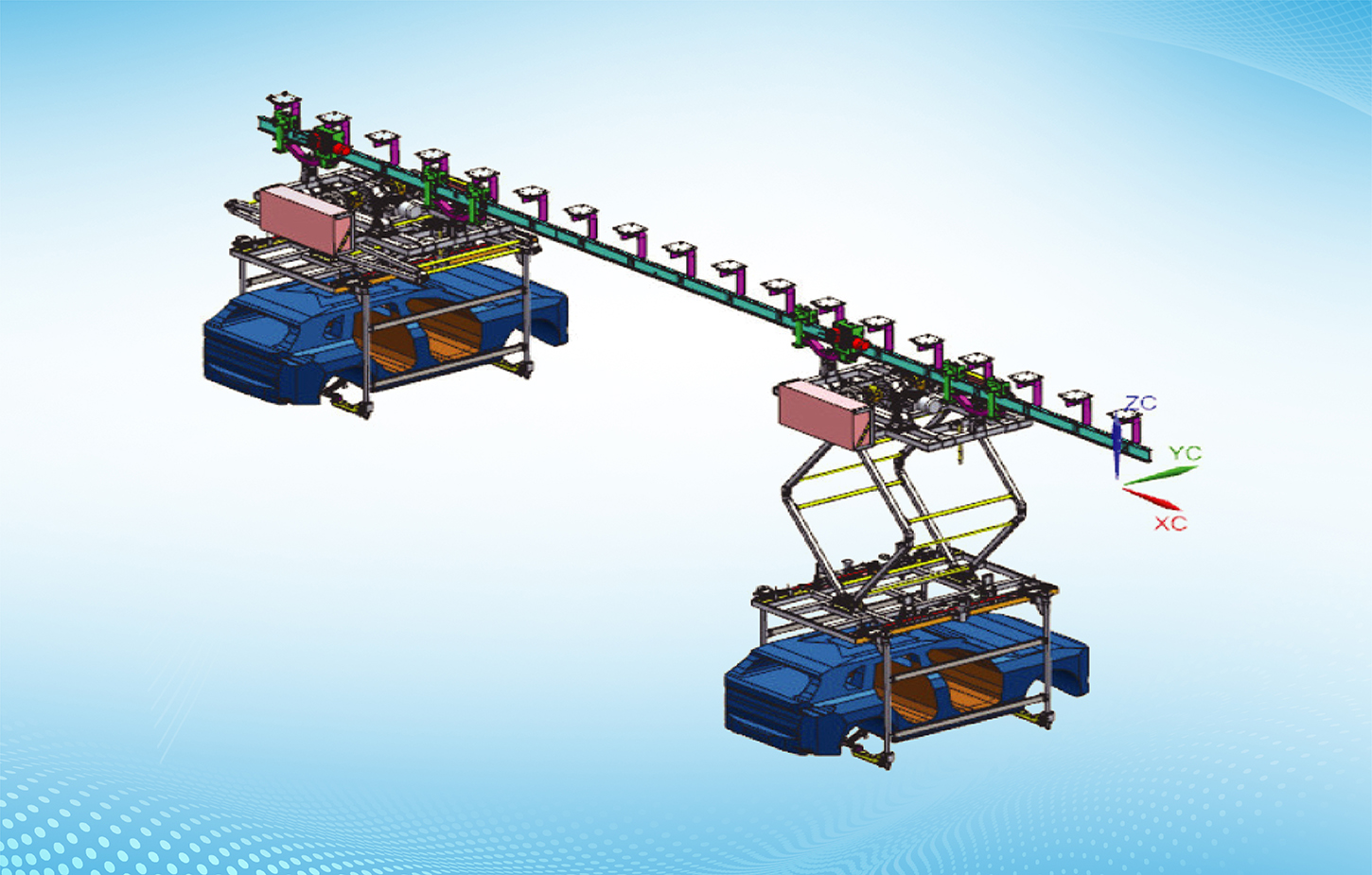

Production is enabled by dedicated industrial equipment assembly lines, supported by integrated welding, painting, and final assembly production lines.

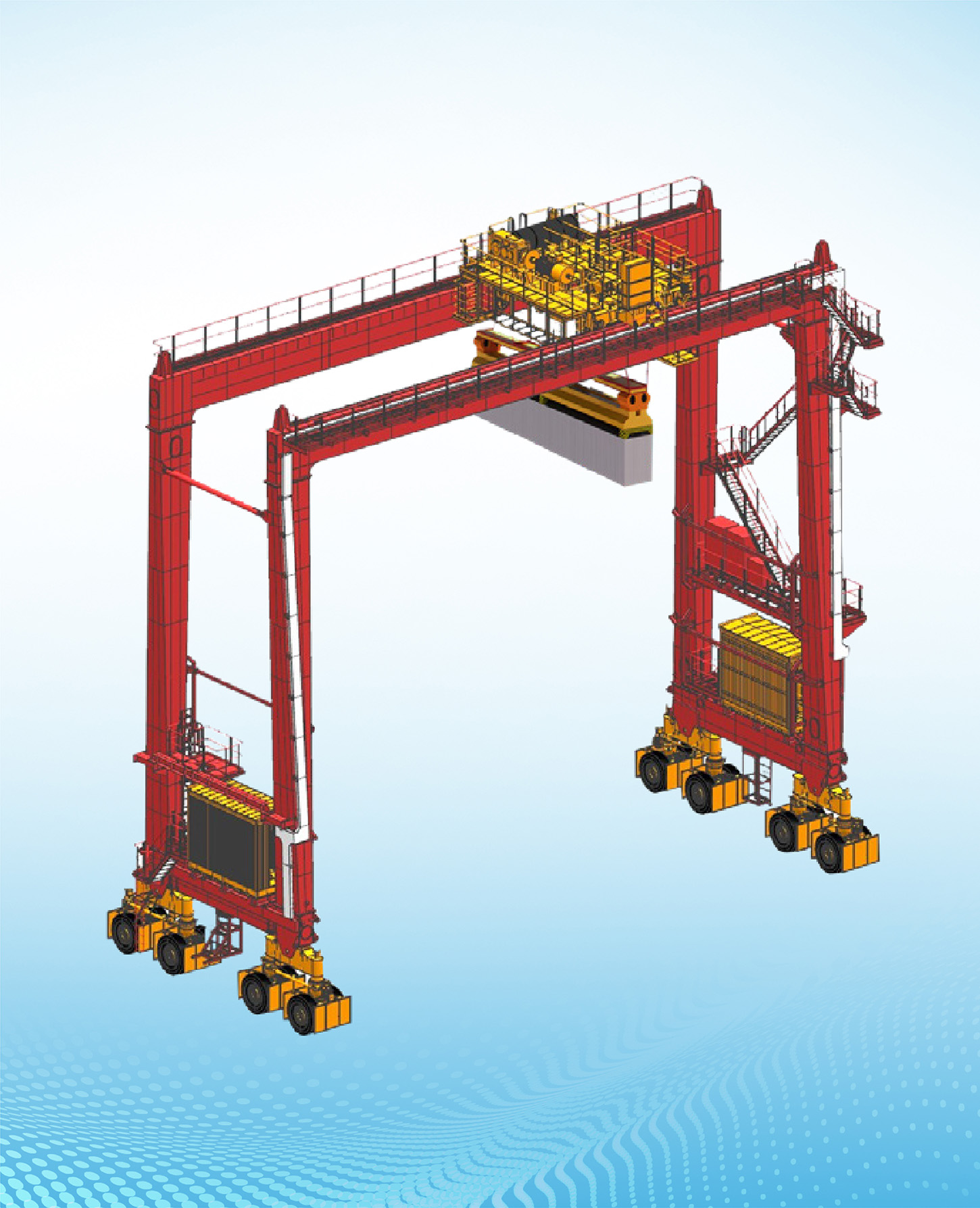

Lifting Equipment Manufacturing

Welding operations combine robotic welding lines and manual welding performed by certified welders (positions 1F–5F and 4G–6G), allowing the corporation to meet diverse technical requirements across different product types and standards.

Storage Equipment Manufacturing

Transportation Equipment & Solutions Manufacturing

MANUFACTURING CAPABILITIES & PROCESS FLOW

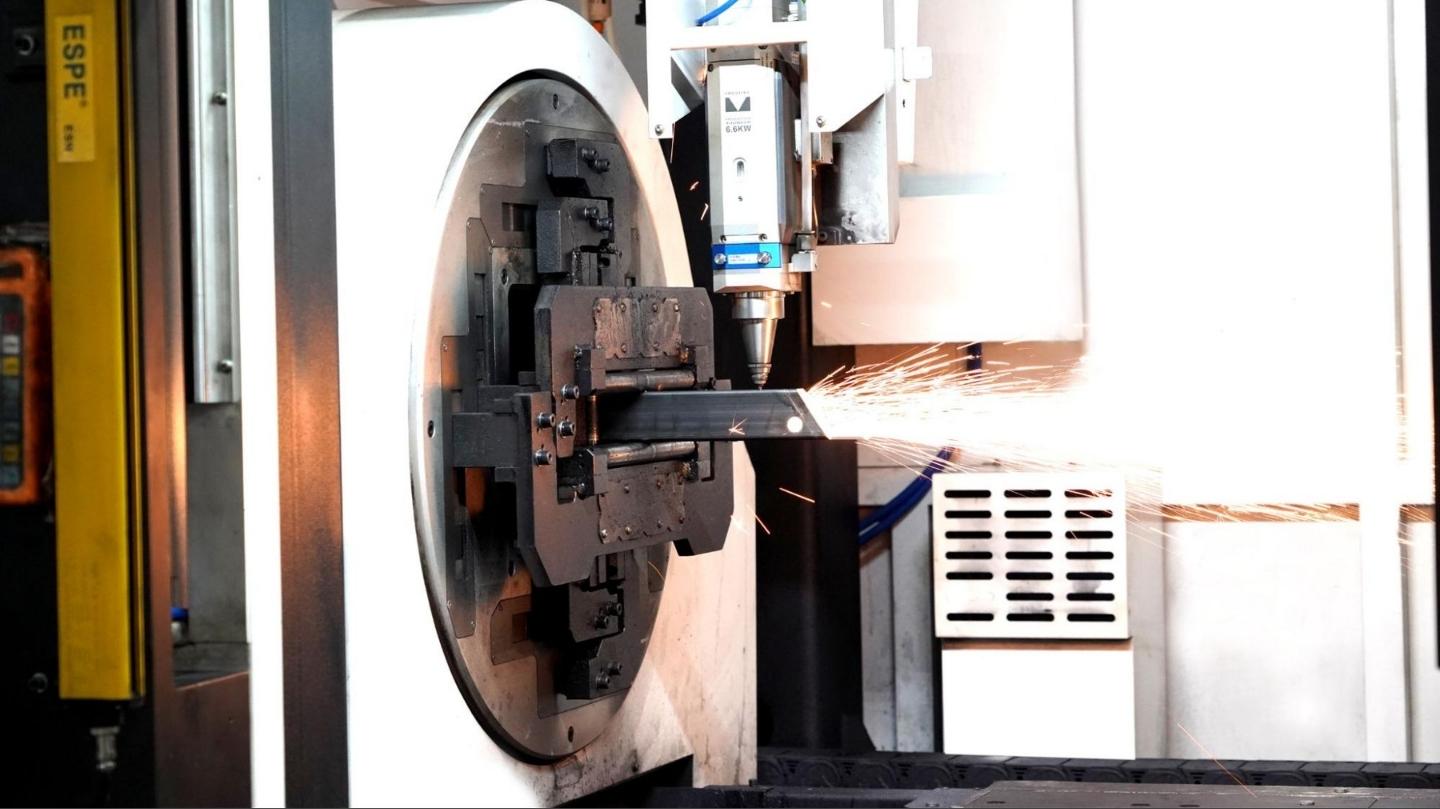

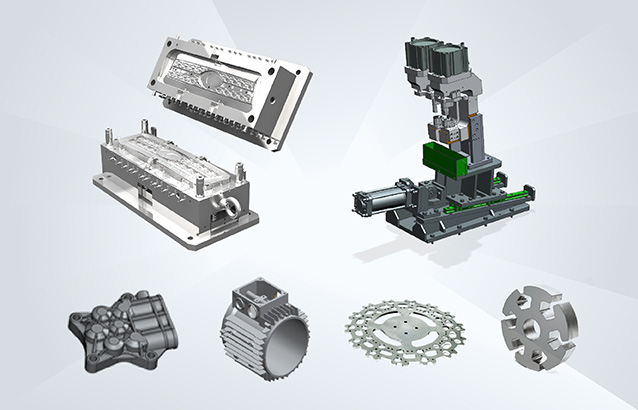

Workpiece Processing

THACO INDUSTRIES begins with billet and plate processing in the mechanical center: slitting, cutting, forming and CNC machining of steel, stainless steel and alloys. Laser cutting, press brakes, rolling lines and multi-axis machining convert raw material into precise parts and substructures that match customer 2D/3D drawings and tolerances.

Welding & Structural Fabrication

Processed parts are transferred to advanced welding lines operated by skilled welders and robotic welding stations, supported by gantry welding, automatic clamping and beam-straightening systems capable of handling steel beams and oversized plate structures. THACO INDUSTRIES’ welding procedures follow AWS D1.1 and AWS D1.2 standards, and are integrated into a quality system certified to ISO 9001, ISO 14001, ISO 45001, IATF 16949, EN 1090 and ISO 3834 for structural steel fabrication, ensuring structural strength, durability and consistent weld quality across all industrial equipment assemblies.

Large-scale workshops within the Mechanical Complex (200,000 m²) and the Specialized Equipment Plant (100,000 m²) provide ample space and dedicated lines for heavy and oversized steel structures, while maintaining efficient material flow from cutting and welding through to surface treatment and final assembly.

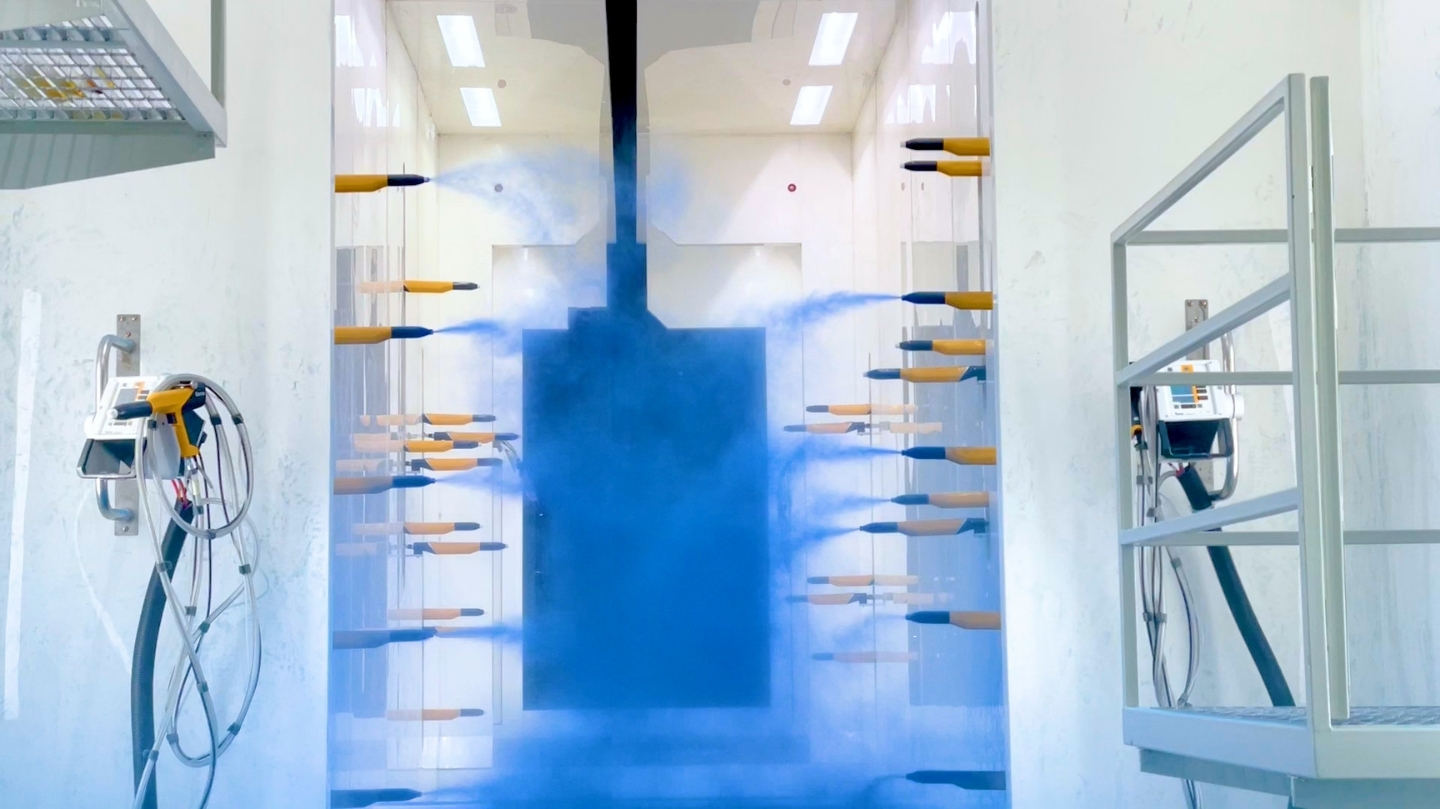

Surface Treatment & Painting

After fabrication, components pass through shot blasting, ED coating, zinc plating, and powder coating lines. Workpieces up to 17,000 mm in length and weighing several tons are cleaned, protected against corrosion, and finished in customer-specified colours. Controlled coating thickness and salt-spray testing ensure durable surfaces suitable for outdoor, marine, and abrasive operating environments.

Assembly, Testing & Delivery

Coated parts go to specialized assembly lines where mechanical, hydraulic and electrical systems are integrated into finished industrial equipment. Dimensional checks, functional tests and load trials verify performance. Products are then packed, shipped, and when required, installed on site, with logistics and maintenance services supporting long-term reliable operation worldwide

CERTIFICATIONS

OUR MARKETS

FAQs

Can THACO INDUSTRIES supply both components and full machinery?

Can THACO INDUSTRIES produce large, heavy or oversized structures?

How does THACO INDUSTRIES ensure global compliance?

What industries does THACO INDUSTRIES serve internationally?

WHY PARTNER WITH THACO INDUSTRIES

THACO INDUSTRIES offers a fully integrated OEM/ODM manufacturing ecosystem backed by large-scale investment, modern technology, and comprehensive production capabilities. Our Mechanical Center provides an annual capacity of 200,000 tons of steel and 300,000 mechanical products, while the Specialized Equipment Plant adds 16,800 tons of steel structures and 60,000 mechanical assemblies, enabling both mass production and project-based manufacturing.

With centralized R&D, procurement, assembly and installation services, plus global export experience, THACO INDUSTRIES delivers cost-effective, end-to-end solutions that minimize risk, shorten lead time, and give partners a reliable, scalable foundation for OEM and ODM cooperation.