News

OEM vs Contract Manufacturer: Pros, Cons & How to Choose

Choosing between an OEM partner and a contract manufacturer is a critical decision with lasting impact on your business. It affects everything from cost and compliance to the stability of your supply chain. If you get this wrong, you might face missed deadlines, unplanned expenses, or disputes over product ownership.

That’s why understanding the differences at the start is important if you want to avoid setbacks and align production with your long-term goals. This guide walks you through the real differences, the trade-offs on both sides, and the conditions where one model clearly outperforms the other.

What’s the difference between OEM and contract manufacturing?

OEM and contract manufacturing involve outsourced production but differ in roles and responsibilities. OEM typically means building products to your exact design specifications. A contract manufacturer may handle parts of the production or assembly without owning the product design. The key difference lies in control: with an OEM, you retain design and tooling ownership, while contract manufacturers often rely on their existing processes.

View more: What Is Original Equipment Manufacturer (OEM)?

Another key distinction is that OEM partnerships provide integrated engineering and R&D support, whereas contract manufacturing focuses only on production. Similarly, OEM offers more control and customization, while contract manufacturing is often a faster way to launch a product.

What is OEM (Original Equipment Manufacturing)

Original Equipment Manufacturing (OEM) means contracting a third-party factory to build products exactly to your design specifications. Under this model, you own the product design and brand, while the OEM manages production and quality control.

THACO INDUSTRIES, for instance, provides full end-to-end OEM services, from R&D and custom design to fabrication, final assembly, installation, and maintenance.

As your OEM supplier, we support material sourcing, tooling, and testing to deliver products that meet your requirements. To ensure traceability and consistency, we implement strict quality management at every stage (compliant with PPAP Level 3, ISO 9001, IATF 16949, etc.).

What a contract manufacturer does

Contract manufacturing is an outsourced production model in which a factory produces parts or complete products to a client’s specifications. With this option, the client owns the design, while the manufacturer handles key processes such as machining, welding, or assembly. So, instead of investing in equipment or facilities, you purchase output in batches based on demand.

Many contract manufacturers integrate machining, welding, and assembly in one facility, reducing hand-offs and ensuring tighter production schedules. For buyers, that often translates into faster product development and greater confidence that quality will hold from prototype to volume production.

View more: High-quality manufacture and assembly of parts solutions

OEM vs contract manufacturing: Pros and cons

The choice between the two models comes down to priorities. An OEM arrangement gives you stronger control over design and compliance, while contract manufacturing eases capital pressure and can move a project into production sooner. OEM is typically about integration and long-term stability, while contract manufacturing leans toward flexibility and scalability.

View more: Contract Manufacturing Services: Expert Solutions for Global Enterprises

Advantages of OEM

Opting for an OEM partner offers clear structural and operational benefits beyond simple outsourcing. Buyers often highlight the following:

- Integrated production: Housing machining, molding, welding, and assembly under one organization strengthens quality management and reduces variation between stages.

- Economies of scale: Large production runs allow OEMs to deliver competitive unit pricing. This makes long-term contracts more cost-efficient.

- Simplified supply chain: One supplier manages the full process, removing the complexity of coordinating multiple vendors.

- Engineering collaboration: Many OEMs provide design and tooling input, which refines specifications before parts move into volume production.

- Regulatory assurance: Compliance systems and traceability are built in. This is critical for industries where certification and audit readiness are non-negotiable.

Disadvantages of OEM

OEM arrangements require significant upfront investment. You often must pay for custom tooling and molds before production starts. Creating new tooling also adds time, as molds can take months or more to produce. If product designs change or order volumes shrink, the sunk cost in equipment and molds is wasted. This manufacturing model is also less agile. It suits large volumes and stable designs, but can be impractical for prototypes or low-volume runs.

Advantages of contract manufacturing

Contract manufacturing can open practical advantages for businesses that want to stay lean and move quickly. Key benefits include:

- Lower entry costs: You tap into the provider’s existing equipment and facilities, avoiding large capital spending on tooling or factory space.

- Design ownership: The client keeps control of the product design while leaving fabrication and assembly to the manufacturer.

- Faster product development: Established production lines and expertise allow new items to quickly move from prototype to launch.

- Scalability: You can change volumes without major financial penalties, especially in seasonal markets.

- Focus on core work: With production outsourced, your team can allocate more resources to R&D, marketing, or distribution.

Disadvantages of contract manufacturing

Contract manufacturing can pose some risks. IP risk is most notable since you share proprietary designs with a third party. A solution is to enforce intellectual property protections via contracts, patents, and Non-Disclosure Agreements (NDAs). If agreements are weak, your innovations could be compromised.

You also have less direct control over the manufacturing process. This means quality may vary if the partner’s standards or practices differ from yours. Even worse is if you are working across borders, as this adds complexity (language, regulations, distance), which can introduce delays or hidden costs.

| Factor | OEM | Contract Manufacturer |

| Tooling cost vs unit cost | High upfront tooling cost, lower unit cost at scale | Low tooling cost, higher per-unit price |

| Lead time | Long (new tooling needed) | Short (uses existing capacity) |

| Initial investment | High (capital tooling costs) | Low (minimal upfront expense) |

| Payment terms | Large deposits or upfront fees | Flexible, pay per unit |

| IP risk | Lower (you own the design) | Higher (risk of design leakage) |

| Scalability | Economical for high volume | Flexible scaling for volume changes |

When to choose an OEM manufacturer or a Contract manufacturer

Choosing between OEM and contract depends on your priorities. Below, we examine key factors to guide your decision.

Quality and compliance

Quality and compliance are top priorities for B2B buyers. In either scenario, vet your supplier’s certifications and track record. At THACO INDUSTRIES, certifications such as ISO 9001, IATF 16949, and PPAP Level 3 guide how every component is built and tested. If you’re considering contract manufacturing instead, a few things shift. You’ll need to verify that your chosen partner holds equivalent credentials or be prepared to audit them regularly to maintain compliance. You should also select the supplier (OEM or contract) whose quality systems meet your industry’s standards. These certifications are mandatory in regulated sectors (auto, medical, etc.).

Cost and commercials

Cost is a key driver, especially when producing your own product. OEM requires a high upfront investment (tooling and equipment), but yields a lower price per unit at scale. By contrast, contract manufacturing shifts costs into each unit, meaning you pay only for what you produce. This frees capital but means higher ongoing unit prices. The payment terms of the two also differ. OEM deals often involve large initial deposits, while contract deals allow pay-per-unit flexibility.

Working with a Vietnam OEM partner such as THACO INDUSTRIES allows buyers to spread tooling costs while maintaining competitive unit pricing. This creates more stable landed costs even when freight rates fluctuate.

IP and legal

With contract manufacturing, you retain IP ownership if properly protected. For OEM agreements, you may grant the manufacturer rights to product modifications; therefore, it is essential to clarify ownership of any new IP. A rule of thumb is to ensure legal agreements that cover confidentiality, liability, and quality warranties. Also consider regulatory requirements such as export controls, environmental standards, etc., as these can vary by supplier location and industry.

Supply chain and geography

In most cases, partnering with an OEM in a key manufacturing hub can improve resilience. THACO INDUSTRIES, for example, is based in Vietnam, hence it taps into Southeast Asia’s extensive parts suppliers and major ports. This yields shorter lead times versus a distant supplier. If you’re producing white-label goods, contract manufacturing in the same region might be better, but an OEM’s scale adds reliability.

THACO INDUSTRIES – Leading OEM Manufacturer in Vietnam

THACO INDUSTRIES delivers end-to-end OEM manufacturing and all-in-one solutions from our 320-hectare complex in Viet Nam, supplying global partners across five continents. We integrate R&D, design, and manufacturing so customers receive complete assemblies built to exact specifications. We even support private label manufacturing, producing finished products that you can brand as your own.

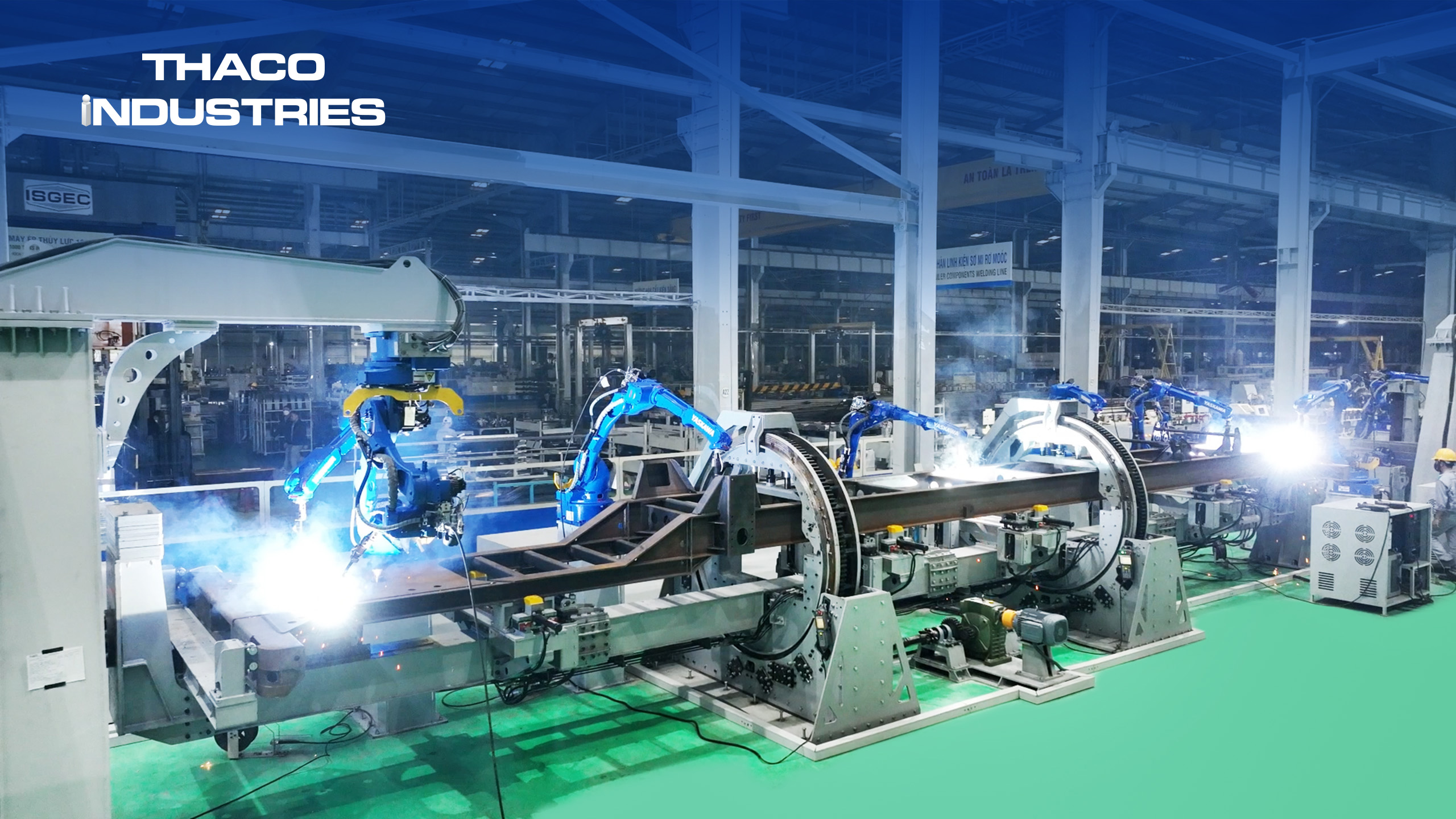

Our manufacturing scale is remarkable. We operate automated lines (laser cutting, robotic welding, coating, heat treatment, etc.) across multiple plants. This allows us to meet high-volume demandshttps://thacoindustries.com/en/contract-manufactu while ensuring consistent quality.

Our global reach is also proven. THACO INDUSTRIES exports components and equipment to North America, Europe, Australia, and Asia. This demonstrates our capacity to deliver worldwide.

Contact THACO INDUSTRIES at partsales@thaco.com.vn or call us +1 310 344-1252 to discuss your next OEM or contract manufacturing project.