Mechanical processing & manufacturing

Automotive Mechanical Components

Industrial Mechanical Equipment

Metal Raw Materials

Mechanical Processing Products

Mining, Forestry & Logging Equipment

Terminal Equipment

Molds

Agricultural Mechanical Equipment

MANUFACTURING CAPABILITIES & PROCESS FLOW

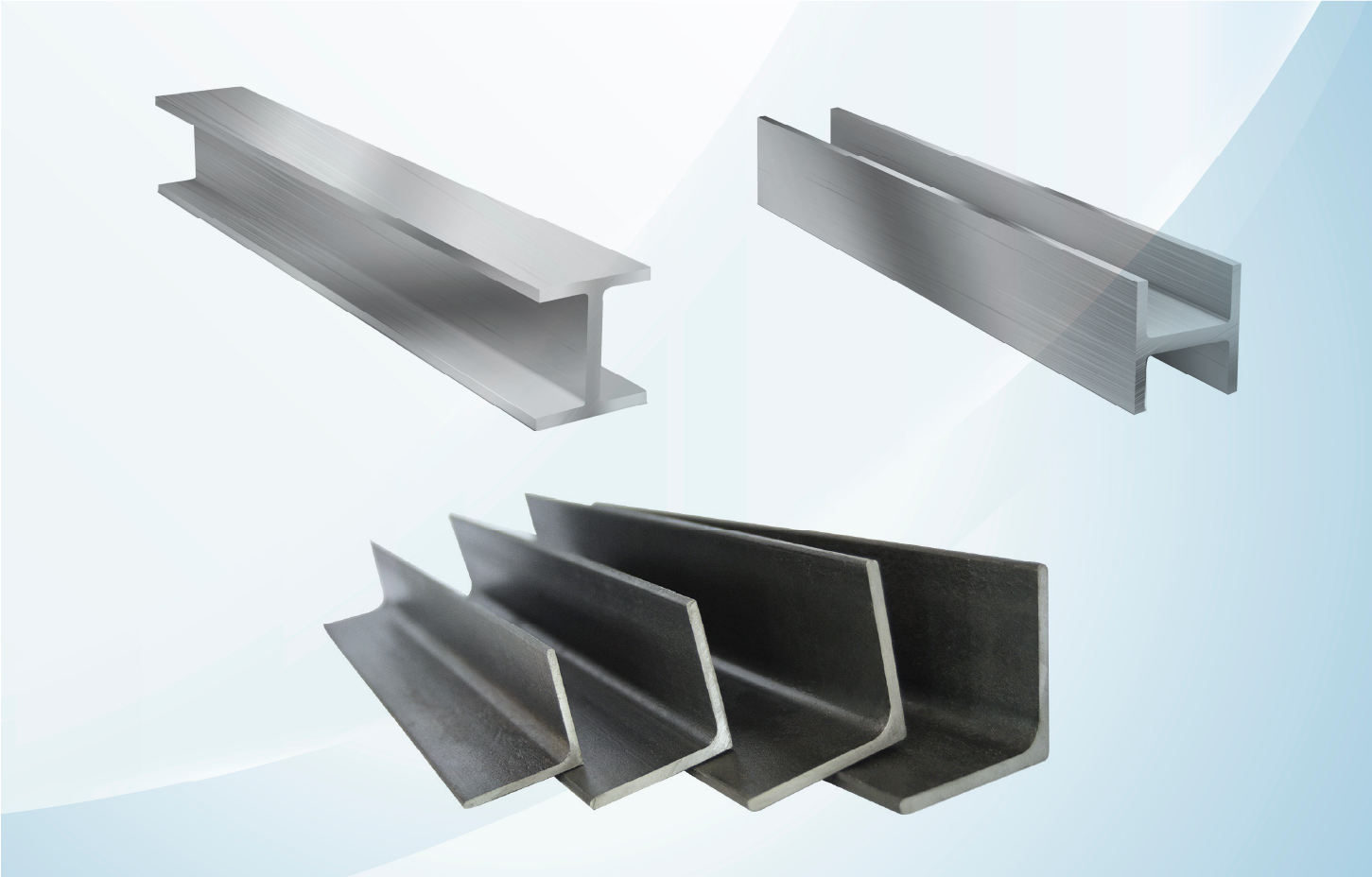

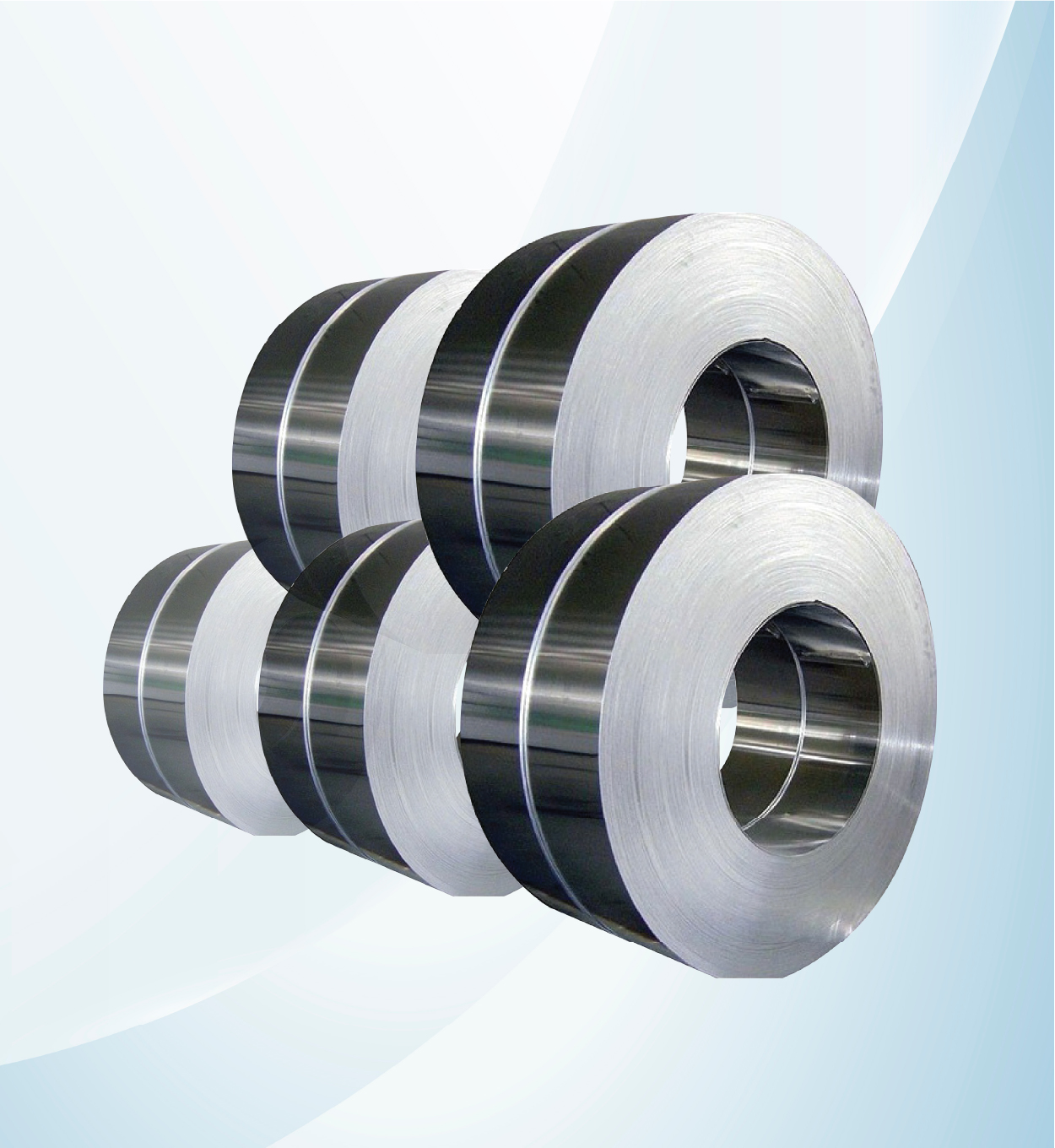

Billet / Raw Material Preparation

THACO INDUSTRIES begins with steel billets and non-ferrous materials processed through slitting lines, sheet-cutting lines, CO₂/laser cutting, plasma/gas cutting, and tube/box-steel forming lines.

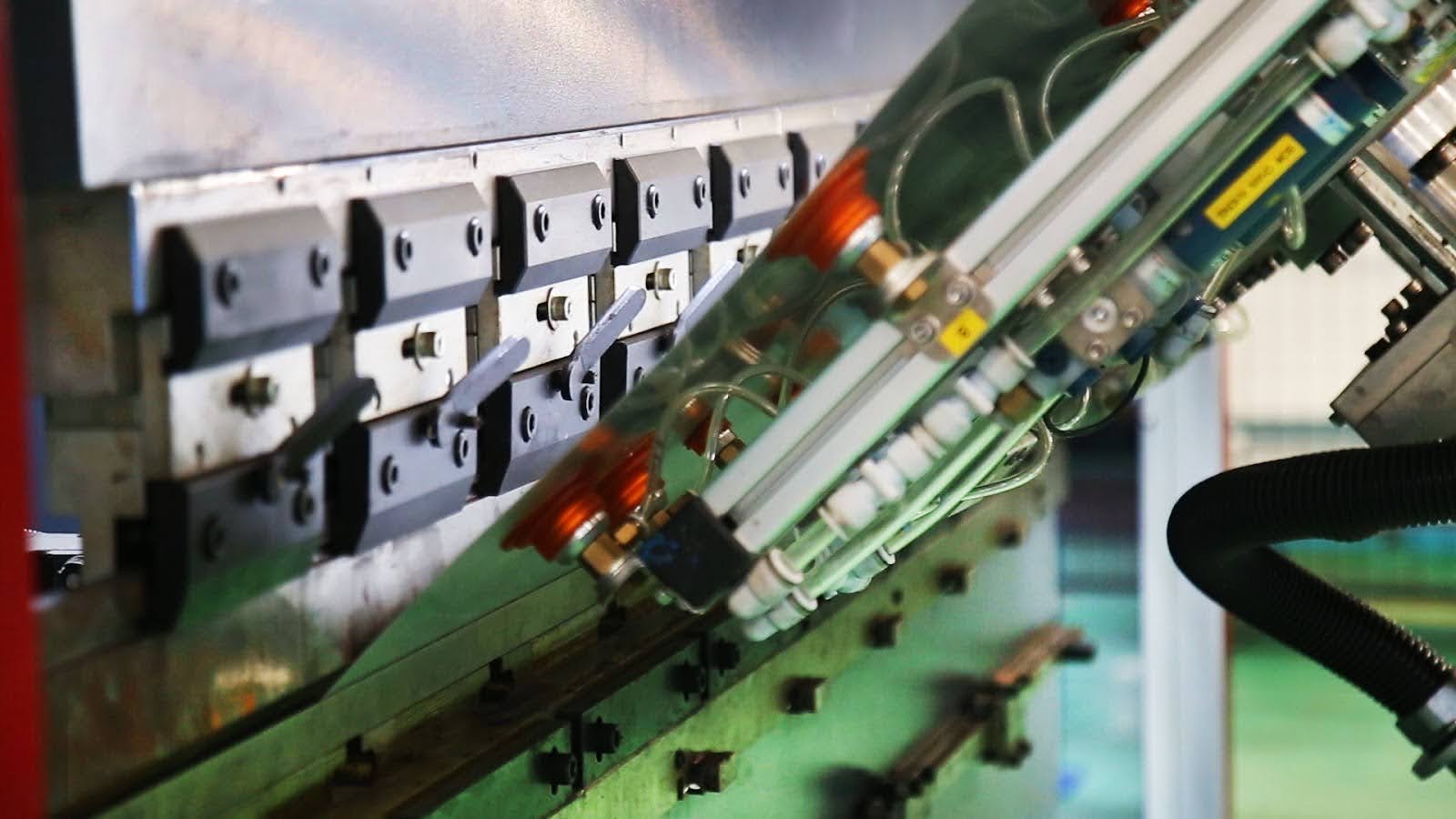

Metal Forming & Shaping

After cutting, materials undergo forming operations using CNC press brakes, hydraulic press machines (60–1,000 tons), automatic roll-forming machines, pipe-bending machines, and punching systems to achieve required dimensions and geometries.

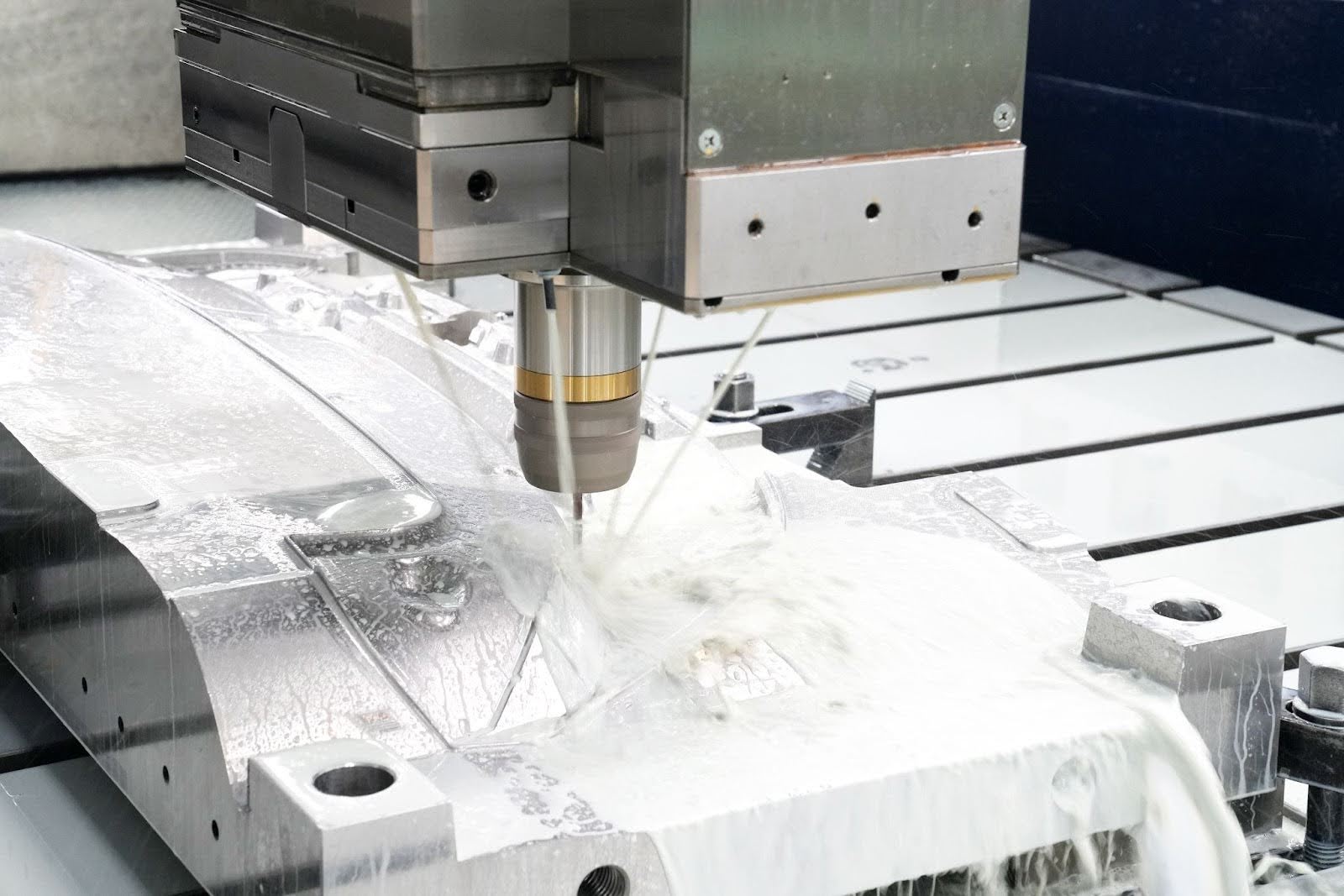

Precision Machining

Complex details are machined using 3-axis to 5-axis CNC milling machines, CNC lathes, deep-hole drilling, wire-cut EDM, and grinding machines. This ensures high-tolerance accuracy for components, molds, and mechanical parts.

Welding & Structural Fabrication

Machined and formed parts are joined using MIG/MAG robotic welding stations (4–12 robots per station), tandem gantry welding, laser welding, and automatic clamping systems. This stage forms large structures such as chassis frames, crane beams, and industrial equipment frames.

Surface Treatment and painting

To improve durability and corrosion resistance, components go through shot-blasting, ED coating (up to 1,000-hour salt spray performance), zinc electroplating, powder coating, and color painting. Powder booths and wet-paint lines (water-based, PU, NC, oil) deliver specified thickness, gloss, and adhesion.

Assembly of Mechanical Products

Parts are assembled on specialized production lines including:

- Crane assembly lines (gantry crane, structural assemblies)

- Truck box assembly lines

- Industrial machinery assembly lines

- Agricultural and specialized equipment assembly

- Electrical cabinet assembly

Quality Control & Testing

QC is conducted at every stage of the manufacturing process, including hardness testing, mechanical material testing machines, CMM measurement, surface roughness measurement, weathering/accelerated ageing tests, and visual/functional inspections to ensure compliance with ISO 9001, ISO 14001, IATF 16949, and EN 1090 standards.

Packaging, Logistics & Delivery

Finished products after quality check are then crated securely for roadway or waterway transport. Large structures are split into manageable modules for assembly on-site.

CERTIFICATIONS

OUR MARKETS

OUR PARTNERS

FAQs

Which industries does THACO INDUSTRIES serve?

Do you support CM/OEM/ODM cooperation models?

How does THACO INDUSTRIES manage quality control?

Does THACO INDUSTRIES support international customers?

Can THACO INDUSTRIES handle large steel structures and oversized equipment?

WHY PARTNER WITH THACO INDUSTRIES

1. Closed-loop production process

THACO INDUSTRIES delivers end-to-end OEM and ODM manufacturing through a fully integrated mechanical ecosystem. Throughout an All-in-one value chain, including Business – Product Research & Development (R&D) – Manufacturing – Delivery – Maintenance, THACO INDUSTRIES ensures tight process control, consistent quality, and optimized lead times across the entire production cycle.

2. Scale and capacity

With a total investment of USD 450 million and operations across 510,000m2, including the Mechanical Complex, Specialized Equipment Plant, Molds Plant, and Civil Equipment Plant. THACO INDUSTRIES supports large-scale, high-precision manufacturing for global customers. Production infrastructure includes 5-axis CNC milling machines, CNC lathes, laser and plasma cutting systems, hydraulic presses up to 1,000 tons, robotic welding lines, and advanced coating systems such as ED coating, powder coating, and zinc plating.

3. R&D and engineering capability

R&D activities are supported by engineers and modern design and simulation software. This enables design optimization, manufacturability improvement, and technical customization to meet specific OEM and ODM requirements across multiple industries.

4. Standards and quality assurance

Quality and compliance are ensured through internationally recognized management and product standards, including ISO 9001, IATF 16949, ISO 14001, and EN 1090. With deep processing capability, strong engineering expertise, and extensive international export experience, THACO INDUSTRIES is a reliable long-term partner for OEM and ODM manufacturing projects.