Product information

What is Mold Machining? Common Methods & CNC Process Explained

In modern industrial manufacturing, mold-making services have rapidly evolved with diverse methods and technologies. Under increasing demands for precision, durability, and cost optimization, many enterprises are turning to advanced machining technologies such as CNC and EDM to enhance productivity and product quality. In this article, THACO INDUSTRIES will help you understand What is mold machining? and explore the most common mold-making methods used today.

What is a mold?

A mold is a tool or device used to shape a product during mass production. Molds are typically made from metals such as steel or aluminum and are precisely designed according to the product’s intended dimensions and geometry.

Depending on the material and manufacturing technology, molds are widely applied across various industries, including:

- Plastics industry: injection molds, extrusion molds, blow molds, compression molds, etc.

- Mechanical manufacturing: die-casting molds, gravity casting molds, cold stamping dies, hot stamping dies, etc.

- Other industries: aluminum casting molds, rubber molds, glass molds, and more.

Molds ensure consistent shape, dimensional accuracy, and uniformity of products while reducing production time—especially beneficial for large-scale manufacturing.

What is mold machining?

Mold machining is the process of designing, manufacturing, and finishing molds used to shape products in industrial mass production. This process requires advanced technology, high precision, durability, and strong load resistance to ensure mold stability and consistent product quality. The application of modern technologies has become increasingly common, helping shorten production time, improve precision, and optimize manufacturing costs for enterprises.

Common mold machining methods today

Below are several of the most commonly used mold machining methods:

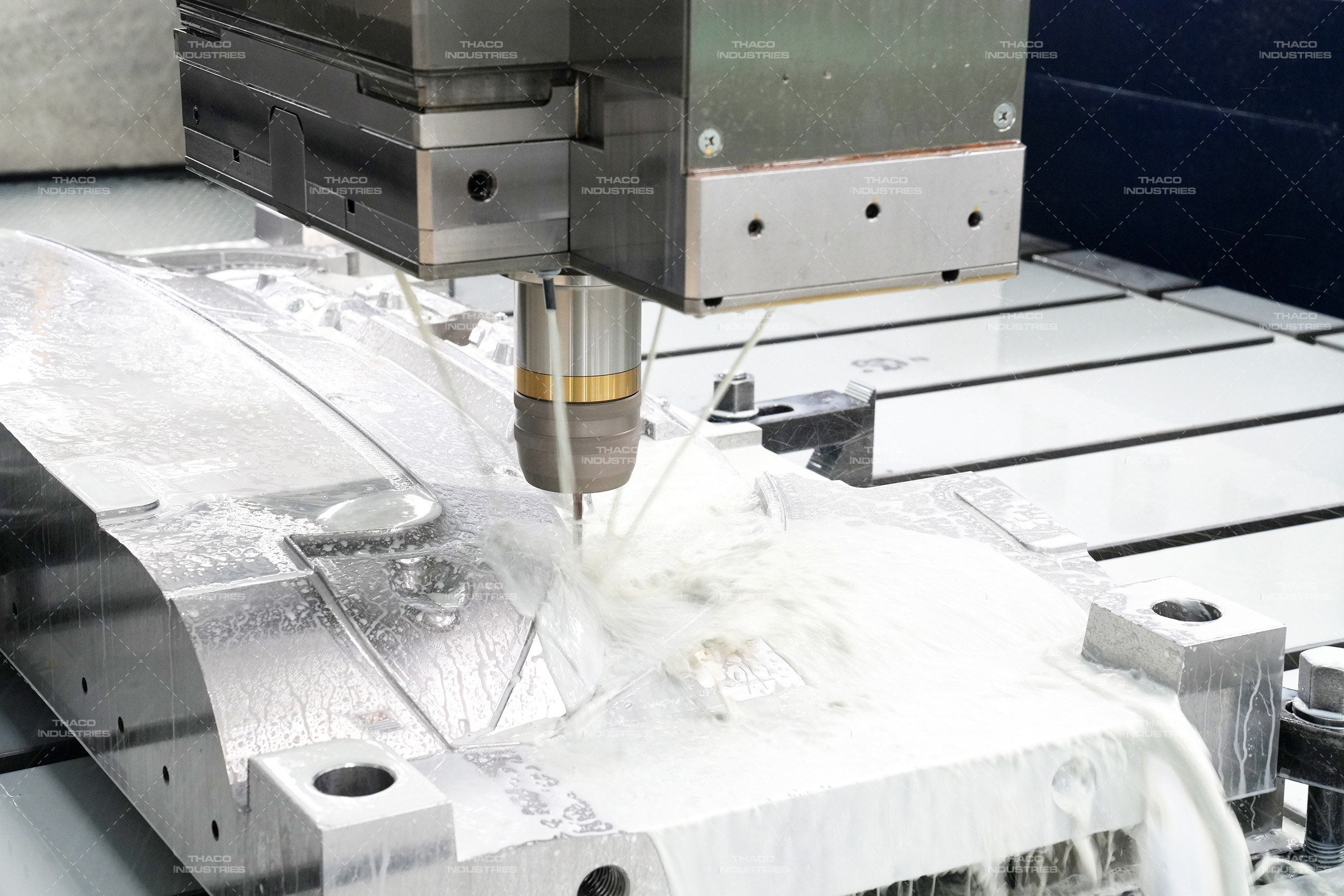

CNC Milling

This CNC mold machining method uses automated machining technology to finish the surfaces of metal or plastic workpieces with high technical requirements, forming mold shapes according to 3D designs. CNC milling provides high accuracy, fast cutting speed, and the ability to machine molds with complex geometries.

CNC Turning

CNC turning is a mechanical machining method that uses computer-controlled lathes, typically for creating round or axis-symmetric components. CNC turning ensures high accuracy and stability in mass production.

Electrical Discharge Machining (EDM)

Also known as spark erosion, EDM machining is a non-contact, high-precision process that removes material from a workpiece using electrical discharges. This method is ideal for machining components with intricate details, deep corners, or high-hardness materials.

Wire-Cut EDM

A specialized EDM technique that uses a fine metal wire to cut mold components with extremely high accuracy. It is suitable for thin or small parts requiring tight tolerances.

Laser Machining

Laser machining uses a high-intensity laser beam to melt, cut, engrave, or treat metal surfaces. Advantages include high speed, smooth cutting edges, and minimal material distortion, making it ideal for engraving logos, micro-details, and high-precision components.

Plasma Cutting

Plasma machining uses a jet of ionized gas (plasma) generated by electrical discharge to cut conductive materials. This high-temperature, high-velocity process is typically used for rough cutting or pre-machining large metal sheets before precision finishing by CNC or EDM.

CNC Mold Machining Process

CNC mold machining involves the use of CNC milling, turning, and other technologies to create mold components based on technical drawings with high accuracy. The process generally includes the following steps:

Step 1. Define technical requirements

First, determine the mold’s technical specifications—dimensions, materials, geometry, and related parameters. This serves as the foundation for accurate mold design and production that meets all technical standards.

Step 2. Mold design

Based on product geometry and specifications, engineers assess feasibility in terms of mold structure, material, configuration, and suitable machining methods. Using specialized software such as Mastercam or AutoCAD, optimal mold designs are developed to ensure the final product meets client requirements.

Step 3. Mold machining

Technologies such as CNC milling, EDM, turning, and grinding are used to fabricate mold components according to the design drawings. Depending on complexity, other tools—such as drilling or cutting machines—may be integrated to achieve precision and optimal finish.

Step 4. Heat treatment

Depending on hardness and durability requirements, molds undergo heat treatment to increase wear resistance and extend service life under demanding working conditions.

Step 5. Assembly and finishing

All mold components are assembled to complete the full mold structure. The mold is then inspected for accuracy, polished, and test-run before being put into production.

Applications of Mold Machining Across Industries

Mold machining plays a vital role in mass production—especially in industries that require fixed shapes, high precision, and reusable tooling. Notable examples include:

Plastics and packaging industry

Mold machining companies use molds to produce electronic components, household appliance parts, motorcycle parts, packaging containers, bottles, and caps with high precision and short production cycles.

Automotive and motorcycle industry

Various molds such as metal stamping dies, plastic injection molds, and aluminum die-casting molds are used to manufacture vehicle components including engine covers, dashboards, door handles, headlights, and fenders.

Electrical and Electronics Industry

Molds in the electrical and electronics industry are used to manufacture device housings, precision plastic components, connectors, contact pins, controllers, and more. This is one of the sectors that demands exceptional precision, safety, and reproducibility to meet strict design and performance requirements of electronic products.

Medical Industry

Mold machining companies in the medical field typically manufacture molds used for producing test tubes, caps, diagnostic devices, medicine containers, and other components that require cleanliness, precision, durability, and safety.

THACO INDUSTRIES – A Reputable Mold-Making Provider in Vietnam

With over 22 years of experience in mechanical machining, THACO INDUSTRIES (a subsidiary of THACO Group) is one of Vietnam’s leading and most reputable mold-making enterprises. The corporation can process molds with dimensions up to 8,000 × 4,650 × 1,800 mm, ensuring machining accuracy of ±0.01 mm — suitable for industrial products requiring high precision and complex detailing.

THACO INDUSTRIES specializes in manufacturing and supplying various types of molds such as: plastic injection molds, cold stamping dies (including blanking, bending, drawing, and compound dies), extrusion molds, and blow molds — all featuring superior quality, diverse types and sizes, serving multiple sectors such as automotive, industrial, agricultural, and civil manufacturing.

THACO INDUSTRIES has invested in state-of-the-art production lines and equipment imported from Germany, Japan, and South Korea, including: 2-column 5-face CNC bed mills, 5-axis machining centers, 5-face gantry mills, mold spotting presses, large drilling machines, dual-head EDM machines, wire-cut machines, and Fiber Laser cutters. Notably, the entire mold manufacturing process is fully automated, integrated with intelligent computer systems and multi-axis cutting tools to enhance machining precision and flexibility for both simple and complex parts.

With a professional mold design team trained in South Korea and experienced specialists, the corporation focuses on Research & Development (R&D),constantly updating and upgrading specialized design and simulation software to produce a wide range of customized products that meet specific customer requirements.

Currently, THACO INDUSTRIES continues to research and develop new products such as PU Foam molds and Thermoforming molds, while expanding its domestic customer base and export markets to the United States, Canada, South Korea, and other countries.

For detailed consultation and support, please contact our hotline: 0348620063.