Product information

What Are Truck Leaf Springs? Structure & Maintenance

Leaf springs are critical components in a truck’s suspension system. They carry vehicle load directly from the frame to the axle, absorb road shocks, and stabilize the vehicle in motion. Understanding their structure and maintenance process helps you select the right components and service procedures when replacements are required.

What is a truck leaf spring?

Truck leaf springs are part of the suspension system. Its primary job is to absorb shocks when the truck travels on rough roads so the vehicle runs smoother and safer on rough surfaces. A leaf spring assembly is made from stacked spring-steel plates, typically arranged from shortest to longest to form a preset camber. More leaves generally deliver a higher spring rate and greater load capacity. When a spring fails, you may see rear-end or front-end instability and uneven tyre wear.

Construction of a truck leaf spring

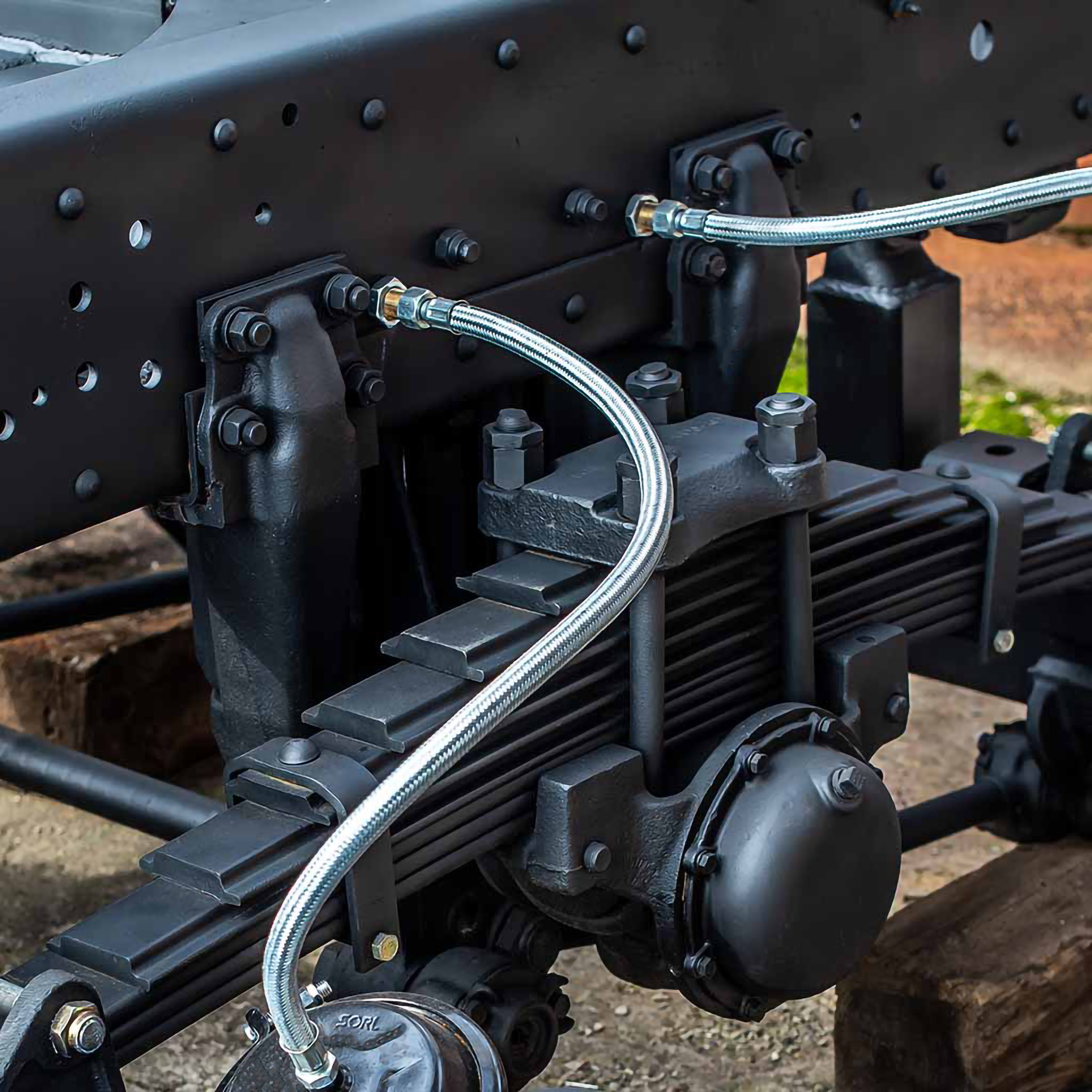

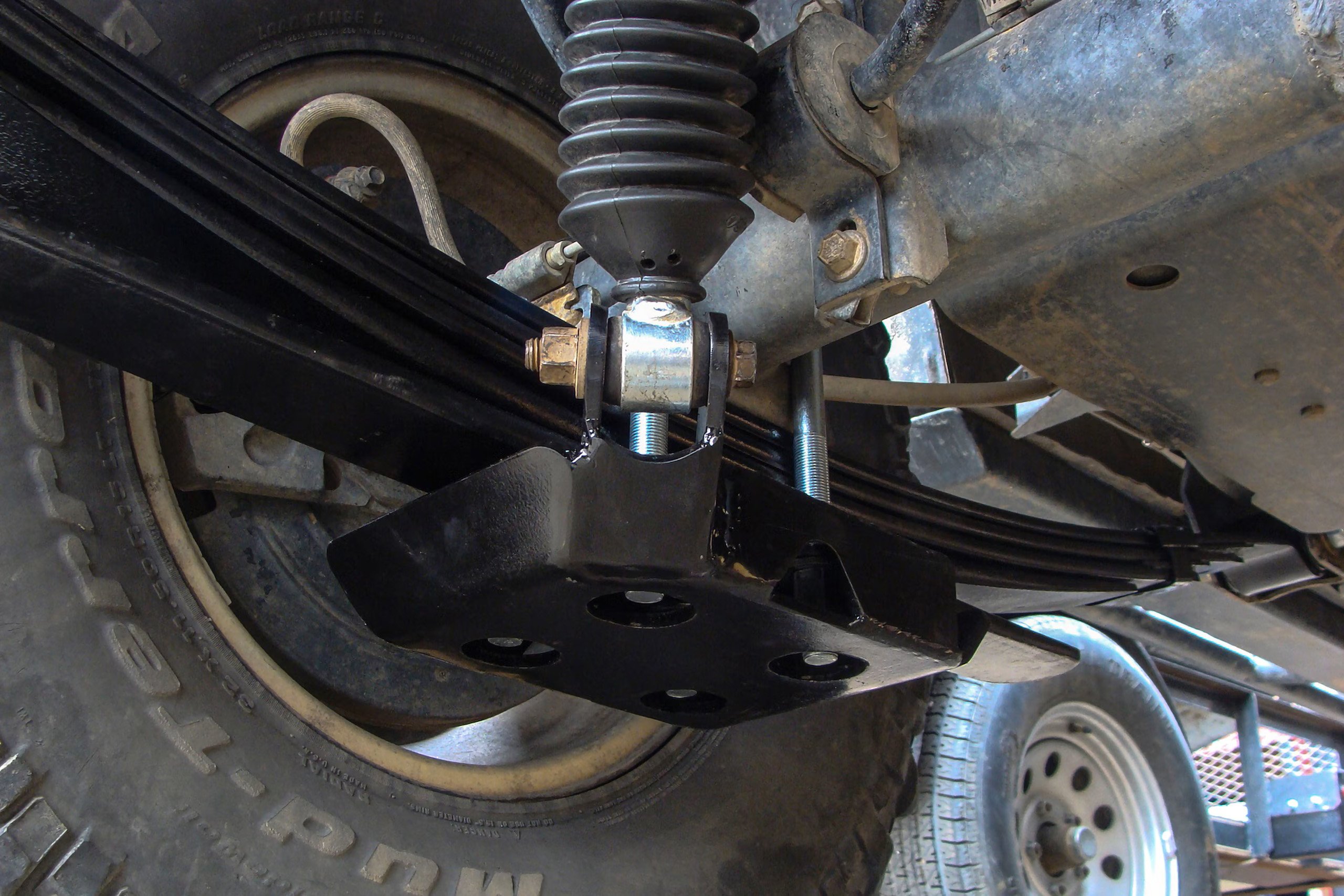

A truck leaf spring includes the following main parts:

- Spring leaves (leaf pack): high-tensile spring steel plates stacked to a defined camber.

- Spring eye bushings: Polymer or metal sleeves fitted into the eyes at each end of the main leaf, reducing friction and wear between the spring eye and the shackle pin..

- Center bolt & clips/clamps: Secure and align the leaf pack as a unit; prevent lateral shift of the leaves.

- U-bolts & fasteners: Clamp the axle to the spring seat and secure the assembly to the chassis.

- Shackles & hangers: Connect the spring to the frame and allow for changes in spring length as it deflects under load.

- Shock absorbers: Control oscillation transmitted from the spring to the frame.

Types of truck springs

- Multi-leaf springs: The most common for commercial trucks. Strengths: cost-effective, robust, straightforward to service. Trade-off: ride comfort is limited compared with other spring types.

- Coil springs (helical): Compact and lightweight, offering good ride quality and resistance to sagging. Trade-off: higher cost in heavy-duty applications and more complex service in some layouts.

- Air springs (air bellows): Provide the best ride comfort and height leveling under varying loads. Trade-off: bulkier packaging and more complex service; requires air system integrity.

- Parabolic leaf springs: The leaves have a parabolic thickness profile, which reduces interleaf friction and improves comfort while maintaining load capacity. Trade-off: higher cost and more specialized service.

How truck leaf springs work

Leaf springs rely on the elastic deflection of spring steel. When the wheels hit bumps, road forces bend the leaves. The spring compresses, stores energy, and then returns to its original shape, absorbing impact and reducing vibration transmitted to the frame and cab.

Signs your leaf springs need maintenance

Excessive vibration on rough roads

The most common sign of a spring problem. Because the spring’s job is to absorb shocks, weakened or damaged springs lose effectiveness, causing the vehicle to shake noticeably over rough roads, potholes, or under heavy loads.

Unusual noises from the spring area

Noise can occur when dry interfaces rub due to insufficient lubrication, or if leaves are cracked or broken. Investigate immediately when you hear unfamiliar sounds around the spring.

Leaves bent, cracked, or broken

A severe failure mode. If you find bent, cracked, or broken leaves, replace the spring promptly to protect occupants and cargo.

Vehicle pulls or wanders while driving

Leaf springs play a key role in vehicle stability. When they are damaged, the truck may drift off-line, especially when cornering or at higher speeds.

Uneven tire wear

If tires are wearing unevenly, the spring system may be at fault. Weak or damaged springs can distribute weight unevenly across the wheels, accelerating irregular wear.

Ride height is lower than normal

A fatigued or damaged spring can lose camber, causing the vehicle to sit lower than usual – an easy sign to spot.

Leaf spring maintenance procedure

Tools & materials

– Vehicle lift or rated jack stands

– Pliers, wrenches, and a socket set

– Hammer

– Stiff brush

– Suitable lubricant

– Clean rags

– Rubber pads or bushings (if needed)

Inspect the leaf springs

Check the following leaf spiring’s components:

– Inspect leaves for bending, cracks, or breaks.

– Ensure leaf spring bolts and center bolt are not loose or corroded.

– Check the center bolt and clips/clamps for wear or damage.

– Inspect spring eye bushings for cracking, tearing, or aging.

– Examine related suspension parts such as the stabilizer bar and shock absorbers for damage.

Clean the assembly

Use a brush to remove dirt and mud from the springs, then wipe all components clean with rags.

Lubricate

Apply the appropriate lubricant to moving interfaces and fasteners per OEM guidance. Lubricate evenly and adequately to ensure smooth operation.

Reassemble

Reinstall all components in their original positions and torque fasteners to specified values.

Thaco Parts – Vietnam’s leading, trusted OEM parts manufacturer

As a strategic partner to many global automakers, Thaco Parts (a division of THACO INDUSTRIES) manufactures and supplies OEM components (glass, leaf springs, HVAC units, wiring harnesses, condensers, interior and exterior parts) to automakers such as Kia, Mazda, Peugeot, Toyota, Hyundai, and Isuzu, and exports to markets including the United States, Australia, Russia, Canada, South Korea, Japan, and more.

THACO Parts’ products comply with IATF 16949:2016, ISO 9001:2015, and ISO 14001:2015. With a deep understanding of global OEM requirements and production processes, THACO Parts develops localization roadmaps aligned with automakers’ standards.