Product information

Understanding Laser Cutting Technology

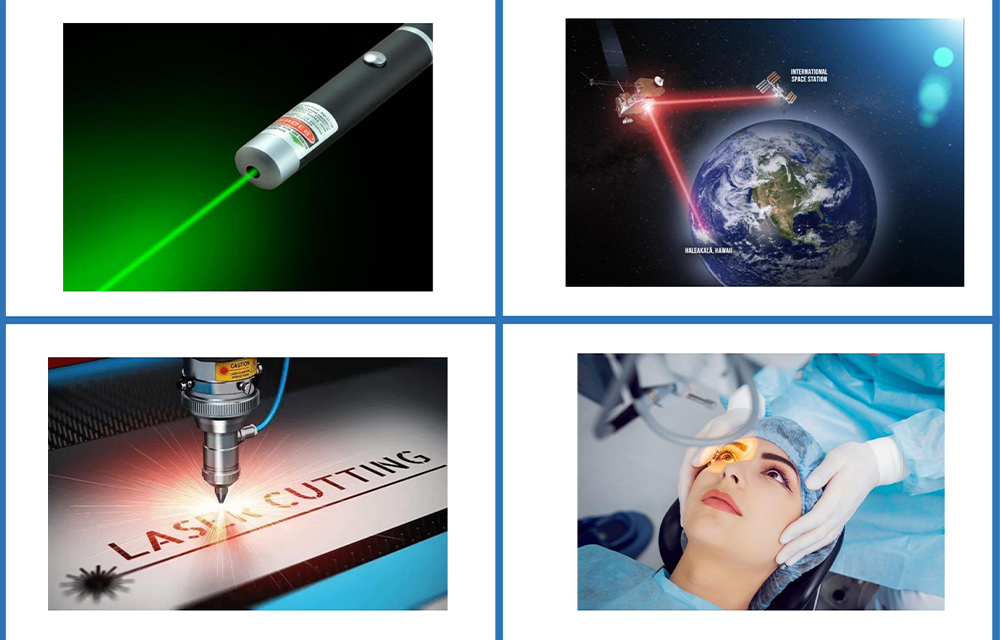

LASER stands for Light Amplification by Stimulated Emission of Radiation.

A laser is an artificial light source generated by stimulated emission within an inverted energy state of a medium.

What is Laser Cutting Technology?

Laser cutting is a modern technology that uses highly focused laser beams to cut both metal and non-metal materials. The process is fully automated, operating according to pre-programmed machine settings.

It is regarded as one of today’s most advanced metal processing technologies today, applied across various industries, including mechanical engineering, medicine, defense, and manufacturing.

* Advantages of Laser Cutting Technology:

- Delivers precise, clean, and visually appealing results across diverse profiles and materials.

- CNC control systems offer features such as size adjustment, pausing, and acceleration, helping save time and simplify operations.

- Maximizes the use of raw materials with minimal waste.

- Suitable for producing diverse product types.

- Machines are equipped with laser shields, along with automatic dust extraction and filtration systems, ensuring a clean workspace and safeguarding operator health.

* Working Principle of a Laser Cutting Machine:

A power source generates a laser beam, which is directed to the cutting head. The head is fitted with a converging lens that focuses the beam, concentrating its energy on the workpiece fixed on the cutting table.

Depending on the material type and thickness, supporting gases such as oxygen or nitrogen are used during cutting. The controller manages the movement of the cutting head and the delivery of the laser beam. A cooling system is essential to dissipate heat and maintain stable operation during the process.

* Common Types of Laser Cutting Machines:

- CO₂ Laser Cutting Machines: Operate by using a flow of CO₂ gas stimulated by a power source to emit high-energy light. They are capable of cutting both metal and non-metal materials.

- Fiber Laser Cutting Machines: A more advanced and widely used technology today. They generate a high-power, high-density laser beam through optical fibers, which is then projected onto the material’s surface to melt and vaporize it. Fiber lasers are known for their precision, speed, particularly in cutting metals.

Application of Laser Cutting Technology at THACO INDUSTRIES Mechanical Complex

To improve productivity and increase the technological value of its products, the THACO INDUSTRIES Mechanical Complex has invested in modern machinery and advanced technologies, including Fiber Laser cutting systems.

09 sheet laser cutting machines (3–15 kW), compliant with European standards.

- Capable of processing sheets starting from 1.5 x 3 m.

- Maximum cutting speed of up to 50 m/min.

- A 15 kW Swiss-made machine can cut sheets up to 2.5 x 6.5 m in size and 40 mm thick.

- A 6 kW Swiss-made machine can cut sheets up to 12 x 2 m in size.

02 tube laser cutting machines (2–3 kW) designed for cutting steel pipes and profiles.

- Handles pipe diameters from Ø20 to Ø220 mm.

- Cuts square steel from 20 x 20 to 220 x 220 mm.

- Maximum product length: 6 m.

- Maximum thickness: 10 mm.

|

|

Key Advantages of THACO’s Laser Cutting Equipment:

- Smart programming: Software-based programming makes operations flexible, enabling the production of multiple products simultaneously while saving time and costs. They are also equipped with automatic correction systems that adjust positioning, ensuring highly accurate cuts—even on complex contours.

- Ease of use and safety: Touchscreen control panels ensure simple operation. A built-in safety system monitors performance and issues proactive warnings. The cutting head automatically adjusts its distance from the material to ensure both precision and operator safety.

- Durable construction: Constructed from high-strength, durable materials, these machines deliver stable performance across a wide range of metals, dimensions.

- Versatile performance: Works effectively on all metals, particularly stainless steel and aluminum.

To reduce costs and remain competitive, the complex has also invested in oxygen and liquid nitrogen tanks with purity levels up to 99.99% to support the laser cutting process.

In addition, THACO INDUSTRIES implements an annual investment and maintenance plan to sustain productivity and enhance product technology.

Interested in learning more about our laser cutting capabilities or getting a customized quotation? Contact us via email: partsales@thaco.com.vn or hotline: 034 862 0063 today for prompt assistance!