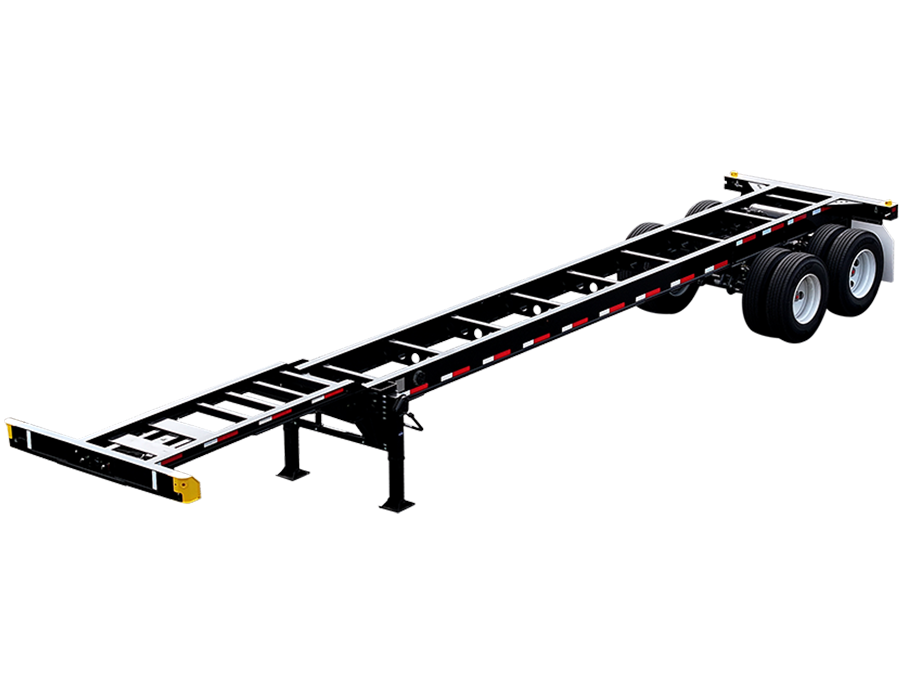

20′ Slider Tandem

Quantity

The requirements of customers

Material

Steel

PRODUCT INFORMATION

| Overall Length | 23’-8” or 27’-8” (extend) |

| Overall Width | 96” |

| Overall Height | 59” |

| Fifth Wheel Height | 48 ± 1” |

| Rear Deck Height | 52 ± 1” |

| Kingpin Location | 30” (From the center of the front bolster) |

| Landing Gear Location | 90” (From the kingpin center) |

| Tandem location | 54” (From rear face of rear bolster to rear axle center when retracted) |

| Axle Spread | 49” |

| Tare Weight | 6,900 lbs±3% |

| Payload | 67,200 lbs |

| Main beam | W12@19lb/ft hot-rolled H-beam, ASTM A572 Grade 50 or equivalent. |

| Cross member | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| Upper Coupler | 5/16” pick up plate with 2” diameter square type king pin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Upper Coupler rails | Fabricated steel. |

| Front Bolster | A572 grade 50 steel U form channel 7” wide x 6” high x 5/16” thick open section. 3/8”x 8” top plate. |

| Rear Bolster | A572 grade 50 steel U form channel 7” wide x 7” high x 5/16” thick open section. 3/8”x 8” top plate. |

| Sliding suspension frame | Rectangular tubing 6” x 4” x 5/16”, ASTM A572 Grade 50 or equivalent. Easily operated self-locating and self-locking spring loaded pin mechanism is used to lock the frame. |

| Rear Bumper | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| License plate bracket | Extending from rear bolster within envelope of ICC bumper. Plate is to contain rear cluster lights, rear fleet number & license plate. |

| Twist Lock | Provided |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are bolted on the main beam as the layout. |

| Suspension | H9700 mechanical tandem suspension, overslung configuration with Thaco Springs (Vietnam) low-arch 3-leaf spring (356-00). |

|

Axles

|

5” round axles with 22,500lb capacity; 71.5” track; 16.5”X7” 4515Q brake. Dust shields are provided. |

| 1.5-28 spline, 5.5” automatic slack adjusters. | |

| Reserved PSI interface; Heat Sensing Labels. | |

| Axle Installation orientation 270 degrees FRONT, chambers UP (1 abs ready front, 1 non abs rear per unit). | |

| Wheel end | Hub & Drum Assembly. 340-4370 solid Aluminum Grease hub cap. Seals P/N Scotseal plus XL 46300. Bearings. Spindle nut Double Nut. |

| Lubricant | Synthetic Semi-fluid grease lubricant. |

| Wheels | 22.5 x 8.25 10-stud hub-piloted wheels with 5 hand holes and with TR572 valve stem. |

| Tires | 11R22.5-14PR tubeless type. |

| Brake System | 110800 spring brake priority valve system and 2S/1M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tank. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights and .180 bullets for others). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | 16-724 plastic material with split pins. |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

| Painting | Abrasive blast of all metal surfaces – not less than SA-2.5 to achieve clean bare steel. Surface will be coated with electrophoresis primer and powder topcoat. Total thickness not less than 80μm after dry membrane. Coating supplier PPG (Vietnam). |

| Marking | Standard configuration (includes Decal, layout, VIN & nameplate). |

| Hubodometer | NONE. |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 24”x24”x1/4” White PVC mud flaps with “customer” logo. |

Semi-trailers are manufactured on a closed line, invested in modern technology. Main beams are made from official imported steel from high quality steel plate manufacturers such as MAANSSHAN steel, POSCO,… with full Mill test quality certificates, CO, CQ origin. The details of each SMRM are cut by laser cutting technology with high precision, aesthetic cuts. It is then assembled into clusters on an optimized and highly automated production line. The product after welding is completed, will be transferred to blasting to clean the metal surface with a surface quality not lower than SA-2.5. The product is powder coated (Dip ED) then painted in a color finish with a coating warranty of up to 7 years.

1. Is your business a trading or manufacturing company?

We are a manufacturer in mechanics and supporting industries with the largest scale in Vietnam.

2. Does your company export?

Yes. Our company has exported products to countries such as USA, Australia, Canada, Korea, Japan, Finland, UAE, Poland, Malaysia...

3. What is your company's payment terms?

We will have a contract. There will be specific terms and regulations on your order's method, time, and payment documents. For export, we use T/T or L/C payment method.

4. How long does it take to complete an order of your company?

With products that are already available, the completion time is short. If you have drawings, we need to research and design them,… so the completion time may be longer.

5. Can we get some samples before mass production?

Customers can always refer to sample products. When they are satisfied, we will proceed to mass production as required.

6. What is your shipping policy?

We provide full logistics services from transportation, customs declaration, export documents, and customs clearance; besides, we strictly control the shipping process to help limit costs incurred and ensure timely delivery.