Product information

Radiator and Condenser Assembly for Automotive Cooling

The radiator and condenser assembly is central to keeping modern vehicles thermally stable, energy-efficient, and protected from thermal overload under diverse operating conditions. As automotive cooling requirements become more demanding, manufacturers must ensure consistent performance, durability, and compliance across every component. In this article, THACO INDUSTRIES provides a clear look at how radiator – condenser systems are engineered, tested, and optimized, helping OEM and Tier-1 partners understand what defines a high-quality thermal management solution.

Overview of Radiator and Condenser Assembly

In a modern vehicle, the cooling system and HVAC system work together to keep both the engine and cabin at optimal temperatures. At the heart of this setup is the radiator and condenser assembly – a compact module that manages heat exchange for the engine coolant and the air-conditioning refrigerant.

Instead of installing these components separately, many automakers now integrate them into a single cooling module. This configuration allows the radiator and condenser to operate in a coordinated airflow path, improving energy transfer and reducing thermal load during demanding driving conditions.

For OEM manufacturers, the integrated design offers several advantages:

- Improved thermal efficiency through optimised airflow and reduced heat loss.

- Better space utilization in increasingly compact engine bays.

- Simplified assembly and maintenance, as the module arrives pre-aligned and ready for installation on the production line.

Overall, the combined radiator–condenser structure supports more reliable vehicle performance, smoother AC operation, and improved long-term durability, essential factors in meeting today’s automotive engineering standards.

Core Components and Working Principles

A radiator and condenser assembly is built around two key heat-exchange units, each designed to manage a different thermal load inside the vehicle.

Radiator Structure

A typical radiator includes a multi-layer core, a network of coolant tubes, densely packed aluminum fins to maximise surface area, and inlet/outlet tanks that guide coolant flow. As engine coolant circulates through the tubes, heat is transferred to the fins and released into the surrounding airflow.

Condenser Structure

The condenser features lightweight aluminum coil tubes, thin cooling fins, and a sealed refrigerant pathway that allows high-pressure refrigerant to flow through multiple passes. This construction ensures efficient heat dissipation before the refrigerant enters the next stage of the HVAC cycle.

How They Work Together

- The radiator releases heat absorbed from the engine, preventing overheating and maintaining a stable operating temperature.

- The condenser removes heat from the compressed refrigerant coming from the AC compressor, enabling effective cabin cooling.

- Shared airflow, generated either by the engine cooling fan or natural wind when the vehicle is in motion, supports both units. This integrated airflow path is why the radiator and condenser are often paired as a single module on modern vehicles.

Together, these components maintain thermal balance for the vehicle’s engine and HVAC system, ensuring durability, performance, and passenger comfort.

Types of Radiator and Condenser Assemblies

Radiator and condenser assemblies are designed in multiple configurations to meet different vehicle platforms, thermal loads, and installation constraints. Below are the most common classifications used across the automotive and heavy-equipment industries.

By System Configuration

- Separate components: In some older or low-load systems, the radiator and condenser are installed as two independent units. This setup offers easier individual replacement but takes up more engine bay space.

- Integrated cooling modules: Modern vehicles and OEM manufacturers increasingly adopt combined modules, where the radiator, condenser, and sometimes the intercooler or fan shroud are integrated into a single assembly. This approach enhances cooling efficiency, reduces weight, shortens assembly time, and ensures tighter performance control.

By Material Composition

- All-aluminum: Lightweight, corrosion-resistant, and widely used in passenger cars and commercial vehicles.

- Copper–brass: Offers excellent heat transfer, typically used in heavy-duty or legacy applications where durability and reparability are priorities.

- Plastic tank and Aluminum core: A cost-effective configuration combining strong thermal performance with reduced weight, widely adopted across mass-market automotive models.

By Application

- Passenger cars: Compact, lightweight assemblies designed for efficient cooling and low noise.

- Commercial Trucks & Buses: Larger modules built to manage high thermal loads during long-haul operation.

- Off-highway vehicles (mining, agriculture, construction): Heavy-duty assemblies capable of withstanding harsh environments, high vibration, and extended engine idling.

These variations allow manufacturers to match the radiator and condenser assembly design with the operational realities and performance demands of each vehicle category.

Common Challenges and Maintenance Practices

Radiator and condenser assemblies operate under high thermal load, fluctuating pressure, and constant exposure to environmental contaminants, so issues can develop over time if the system isn’t inspected regularly. Understanding the common problems and how to address them helps maintain stable engine temperatures and consistent A/C performance.

Frequent Issues Encountered

- Leakage: Cracks in tanks, worn seals, loose fittings, or damaged tubes can cause coolant or refrigerant loss, leading to rapid thermal-performance degradation.

- Corrosion: Moisture, road salt, chemical exposure, and electrolytic corrosion gradually weaken metal surfaces and reduce heat-transfer efficiency.

- Clogged Fins or Tubes: Accumulated contaminants on fins or internal deposits in tubes restrict airflow and coolant circulation, reducing overall cooling efficiency.

- Condenser Pressure Imbalance: A failing expansion valve, restricted refrigerant path, or condenser blockage can create pressure irregularities and diminish A/C cooling capacity.

- Reduced Cooling Output: Over time, mineral deposits and internal scaling can restrict coolant passages and reduce heat-exchange efficiency.

Recommended Maintenance Practices

- Regular Cleaning: Use compressed air or approved cleaning agents to remove contaminants from both sides of the fins without bending or damaging them.

- System Checks: Monitor coolant levels, confirm proper refrigerant pressure, and bleed trapped air from the cooling system to maintain circulation and prevent hot spots.

- Routine Inspection: Look for early signs of damage such as discoloration, moisture marks, or loose fittings.

Warning Signs to Watch For

- Engine Overheating: A clear indication that heat dissipation is compromised.

- Weak A/C Performance: Often caused by condenser inefficiency or low refrigerant.

- Unusual Noises: Rattling, hissing, or fan-related noises may signal internal blockage or mechanical issues.

Staying proactive with these maintenance steps helps extend the lifespan of any radiator and condenser assembly and ensures stable, reliable performance across a wide range of driving conditions.

Key Criteria for Selecting the Right Assembly

Choosing the right radiator and condenser assembly is essential to maintaining stable engine temperature, efficient A/C performance, and long-term vehicle reliability. Whether for passenger cars, commercial fleets, or off-highway equipment, the following criteria help ensure the assembly meets both technical and operational demands.

Thermal Performance & Cooling Capacity

The assembly must deliver sufficient heat-dissipation capability based on engine size, load, and climate conditions. A higher thermal capacity ensures stable operation during heavy-duty use, steep gradients, or high ambient temperatures.

Vehicle Compatibility & Fitment

The module should match the exact specifications of the vehicle platform mounting points, dimensions, tank design, hose connections, and airflow orientation. Proper compatibility reduces installation time and eliminates the risk of vibration or premature wear.

Airflow Efficiency & Weight

Efficient airflow through fins and tubes is crucial for both radiator and condenser performance. Lightweight aluminum cores are often preferred because they improve fuel efficiency while maintaining strong heat-transfer properties.

Corrosion Resistance & Material Durability

Materials such as aluminum cores, anti-corrosion coatings, and plastic end tanks help the assembly withstand moisture, road salt, and chemical exposure. Strong corrosion resistance directly contributes to longer service life and lower maintenance costs.

Compliance With Industry Standards

A reliable assembly should meet key global and OEM requirements, including:

- ISO 9001 – Quality management

- IATF 16949 – Automotive manufacturing standards

- SAE J1994 – Performance and durability requirements for HVAC components

- OEM-specific standards for performance, vibration, and pressure cycles

These certifications ensure consistent quality, safety, and traceability across the manufacturing process.

Lifecycle Cost & Long-Term Reliability

Beyond the initial purchase price, consider ease of replacement, accessibility for maintenance, and durability under real-world operating conditions—high humidity, dusty roads, heavy loads, or stop-and-go urban traffic. A well-engineered assembly reduces downtime and minimizes total cost of ownership.

By evaluating these factors, OEMs, fleet operators, and service providers can select a radiator and condenser assembly that delivers long-lasting, high-performance cooling across diverse vehicle applications.

THACO INDUSTRIES – OEM/ODM Supplier of Radiator and Condenser Assemblies

As an experienced OEM/ODM manufacturer, THACO INDUSTRIES delivers radiator and condenser assemblies engineered for consistent performance, high durability, and compatibility across a wide range of vehicle platforms. The corporation leverages an advanced production ecosystem built to meet global automotive standards and the growing demands of international clients.

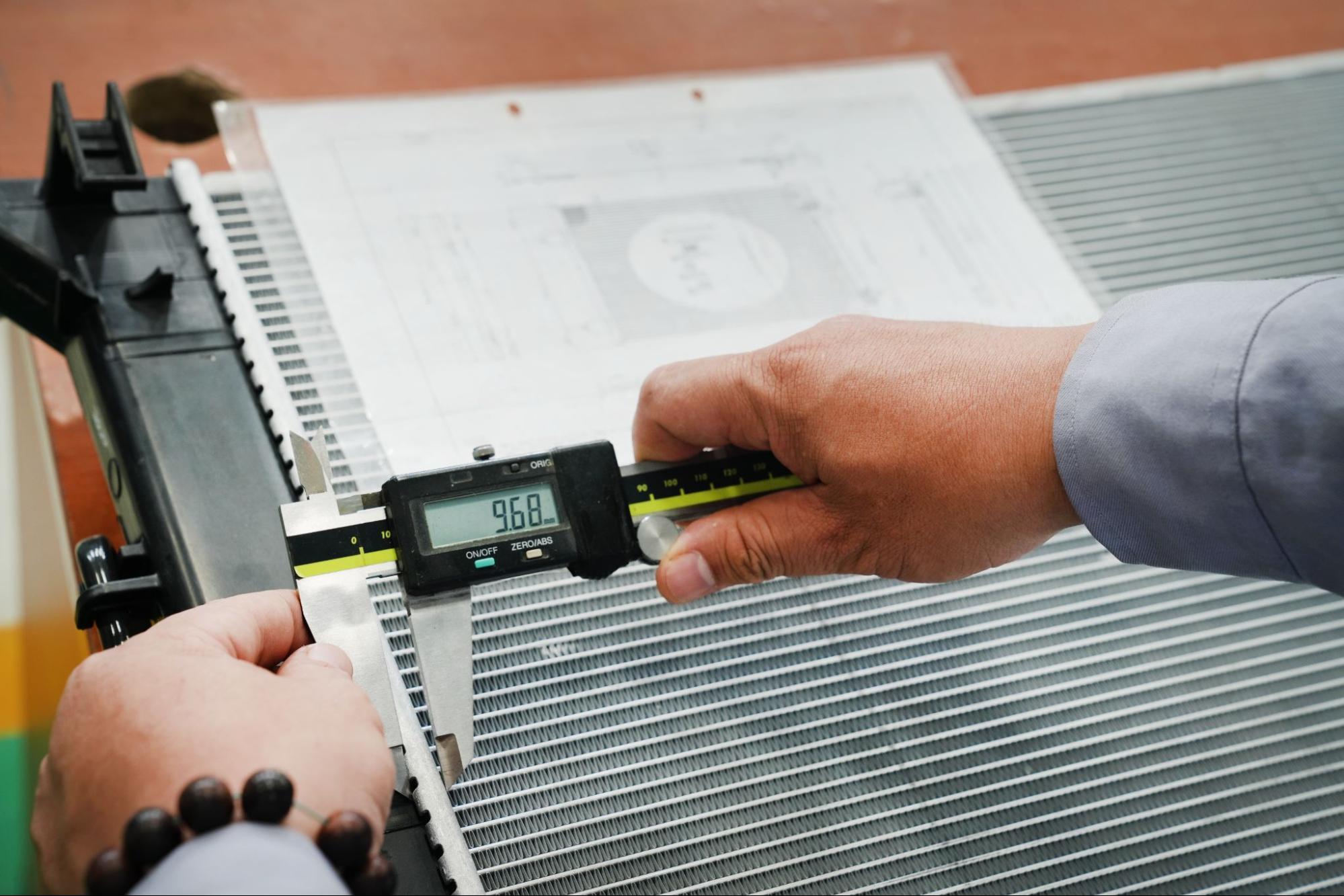

Advanced & Integrated Manufacturing Capabilities

THACO INDUSTRIES operates automated, high-precision production lines equipped with CNC machining systems, robotic welding systems, vacuum brazing furnaces for aluminum cores, and dedicated leak-testing equipment. Each module is assembled on synchronized automated lines to ensure accuracy, consistency, and high-volume productivity. This streamlined workflow enables stable quality control across every stage – processing, brazing, welding, assembly, and final inspection.

Global Standard Certifications

All radiator and condenser assemblies are manufactured under internationally recognized quality and environmental management systems:

- ISO 9001:2015 – Quality Management

- ISO 14001:2015 – Environmental Management

- IATF 16949:2016 – Automotive Quality System

These certifications reinforce the corporation’s commitment to reliability, traceability, and compliance with OEM requirements.

Wide Application Range Across Vehicle Segments

Products are engineered for:

- Passenger cars

- Buses

- Trucks

Each assembly is designed to deliver optimal cooling and HVAC performance based on operating conditions from urban traffic to long-haul routes and extreme environments.

OEM/ODM Customization Capabilities

THACO INDUSTRIES provides flexible, tailored development for global partners, offering:

- Custom sizing and configurations for specific engine layouts

- Material selection to match durability and performance targets

- Optimized fin density, tube design, and tank structure

- Prototyping, testing, and full-scale production under one ecosystem

This approach ensures clients receive cooling modules that fit their technical specifications and adapt seamlessly to their vehicle platforms.

Key Advantages for Global Partners

- Cost-efficient mass manufacturing backed by modern equipment and streamlined processes

- Compliance with international standards and strict quality control

- Flexible customization and reliable lead times for global shipments

- End-to-end support, from engineering and sampling to production and logistics

If you’re looking for a trusted engineering partner, THACO INDUSTRIES provides radiator and condenser assembly solutions designed for safety, performance, and long-term durability.

For customized OEM/ODM development, contact THACO INDUSTRIES at: partsales@thaco.com.vn or +84 348 620 063.