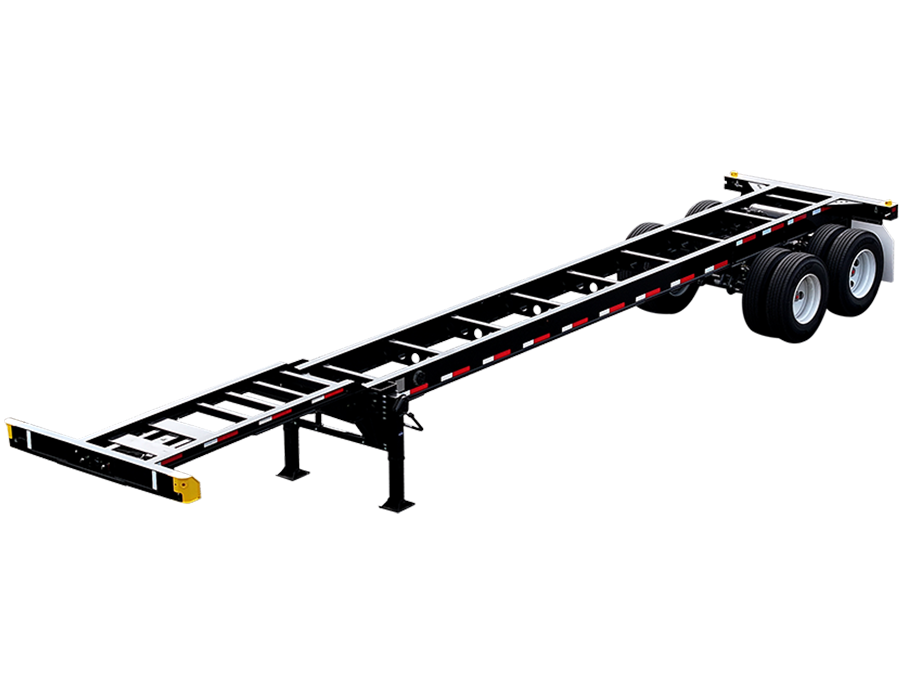

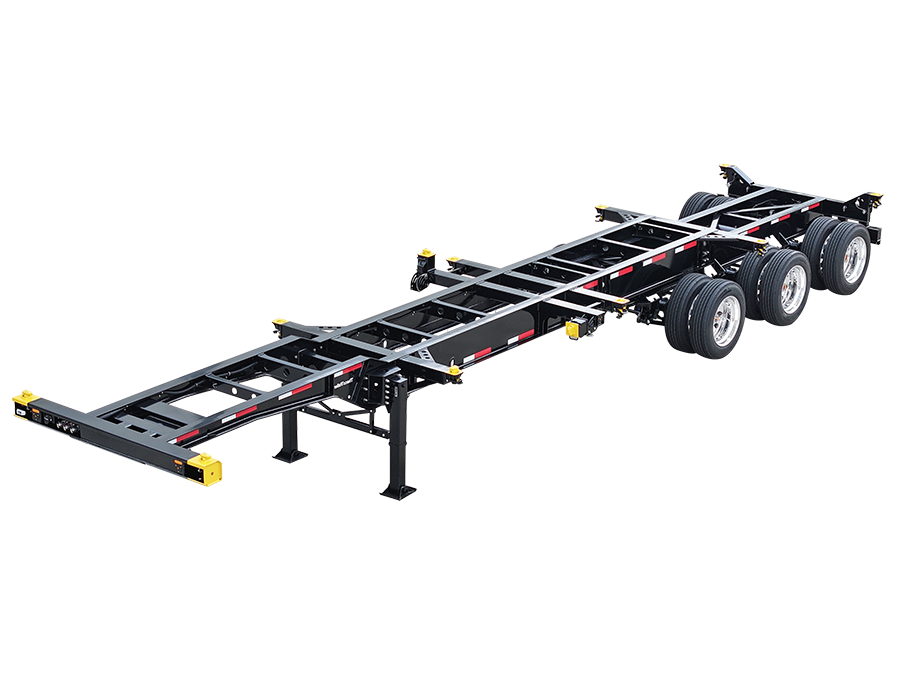

40’ Gooseneck Lightweight Tandem

Quantity

The requirements of customers

Material

Steel

PRODUCT INFORMATION

| Overall Length | 40’-11” |

| Overall Width | 96” |

| Overall Height | 58” |

| Fifth Wheel Height | 48 ± 1” |

| Rear Deck Height | 48 ± 1” |

| Kingpin Location | 18” (From rear face of front bolster) |

| Landing Gear Location | 110” (From the kingpin center) |

| Tandem Location | 52” (From rear face of rear bolster) |

| Axle Spread | 49” |

| Tare Weight | 5,250 lbs ±2% |

| Payload | 67,200 lbs (30,480kgs) |

| Main beam | 13.75” deep x 4″ wide fabricated H-beam, 5/16″ thick Grade 100 steel flange and 1/4″ thick Grade 50 web. |

| Cross member | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| GN member | 5-1/4” deep x 4” wide fabricated H-beam, 5/16” thick flanges and 1/4” thick web. |

| Upper Coupler | 1/4” pick up plate with 2” diameter square type king pin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Front Bolster | 8” wide x 10” high x 3/16” thick open section fabricated by Grade 100 steel, with 3-1/2” chamfer in full length for gathering container in operation. 7-way receptacle and glad hands are in the center of front bolster. Bent corner caps. |

| Rear Bolster | 8” wide x 5/16” thick top plate with 7” wide x 6-5/8” deep x 3/16” thick “U” type bottom channel fabricated by Grade 100 steel. |

| Rear Bumper | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| License plate bracket | Extending from rear bolster within envelope of ICC bumper. Plate is to contain rear cluster lights, rear fleet number & license plate. |

| Front Locking pin | Provided |

| Rear twist Lock | Provided |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are welded on the main beam as the layout. |

| Suspension | Mechanical tandem lightweight suspension with low-arch single spring (363-00). |

|

Axles

|

5-3/4” round axles with 22,500lb capacity; 71.5” track; 16.5”X7” 4515Q brake. Dust shields are provided. |

| 1.5-28 spline, 5.5” automatic slack adjusters. | |

| Reserved PSI interface; Heat Sensing Labels. | |

| Axle Installation orientation 270 degrees FRONT, chambers UP (1 abs ready front, 1 non abs rear per unit). Long studs for installing Aluminum wheels. | |

| Wheel end | 10 stud hub-piloted hubs with lightweight outboard mounting drum. 340-4370 solid Aluminum Grease hub cap. Seals and bearings. Spindle nut: Pro-Torq P/N 447-4743. |

| Lubricant | Petro Canada Precision Synthetic EP00 Semi Fluid Grease lubricant. |

| Wheels | 22.5 x 8.25 hub-piloted Aluminum wheels. |

| Tires | 255/70R22.5-16PR tubeless type. |

| Brake System | 110800 spring brake priority valve system and 2S/1M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tank. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights; PL-10 for Marker/ID/ABS lights and .180 bullets for license light). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | Provided |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

| Painting | Abrasive blast of all metal surfaces – not less than SA-2.5 to achieve clean bare steel. Surface will be coated with electrophoresis primer and powder topcoat, Total thickness not less than 80μm after dry membrane. Coating supplier PPG (Vietnam). |

| Marking | Standard configuration (includes Decal, layout, VIN, nameplate). |

| Hubodometer | NONE. |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 30”x24”x1/4” White PVC mud flaps without “customer” logo. |