Product information

Powder-coated outdoor furniture: Durable and stylish choice

Powder-coated outdoor furniture is increasingly adopted as buyers prioritize durability, corrosion-resistant products that can maintain their appearance and structural stability in changing weather conditions. In this article, THACO INDUSTRIES explores why powder coating is widely trusted for outdoor applications and how it supports long-term product performance.

What is powder-coated outdoor furniture?

Powder-coated outdoor furniture refers to aluminium or steel products finished with a dry powder coating instead of traditional wet paint.

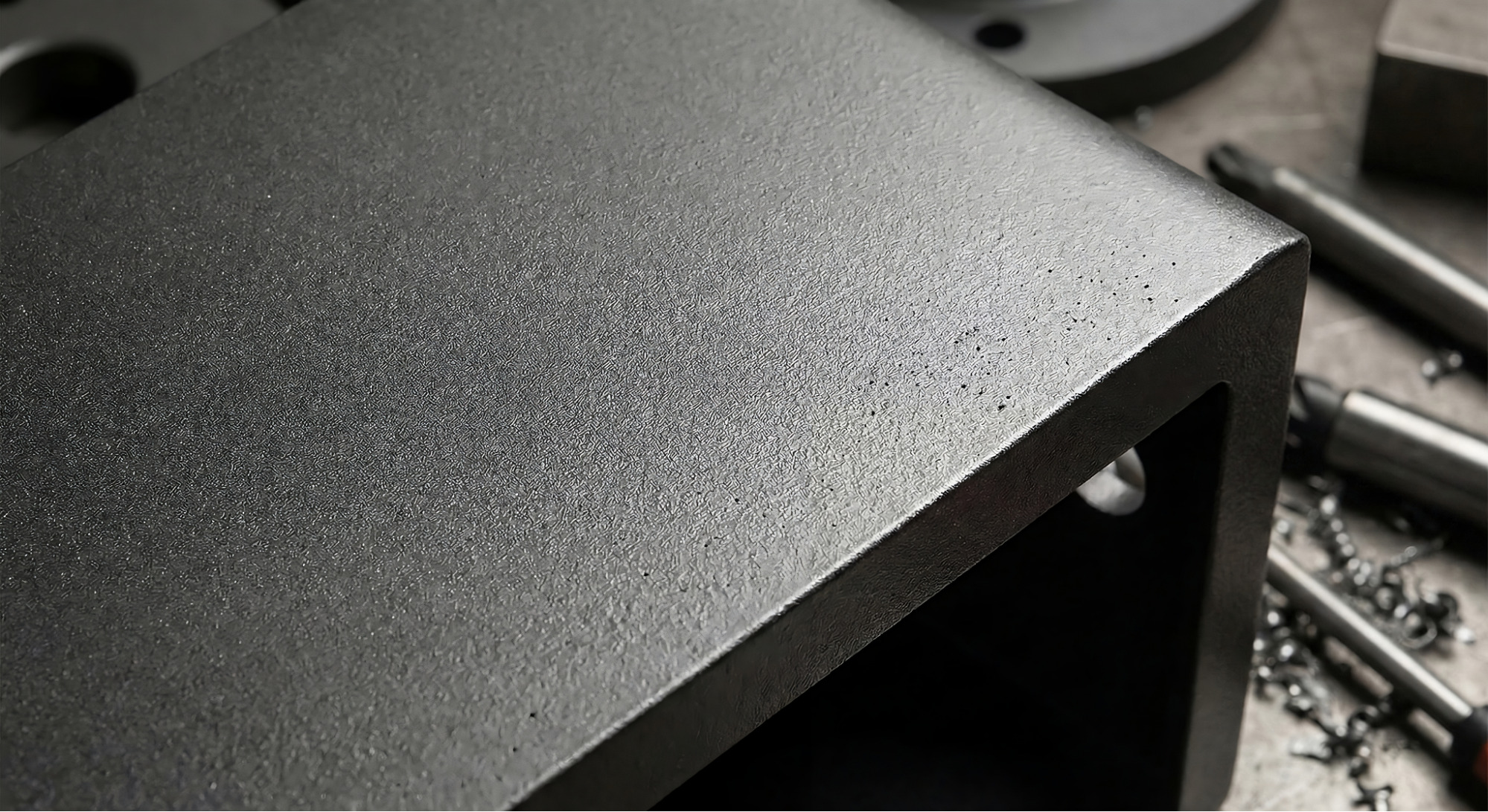

In this process, electrostatically charged powder is applied to the metal surface and then cured under high heat, forming a hard, uniform protective layer that provides strong resistance to corrosion, scratches, UV rays, and harsh weather conditions.

This solvent-free coating bonds strongly to metal surfaces and offers a more eco-friendly, cost-effective alternative to traditional wet painting.

Key benefits of powder-coated outdoor furniture

Powder-coated outdoor furniture offers a combination of strength, weather resistance, and customizable design, making it a reliable choice for residential and commercial environments. As a result, these features translate into core advantages that matter most to B2B buyers, especially in the EU market.

Exceptional durability for European climates

Powder-coating forms a highly protective barrier that withstands rain, frost, humidity, and UV radiation. This level of performance makes it suitable for long-term outdoor use across Europe’s diverse climates, from coastal moisture to winter freeze.

Low maintenance for B2B operators

Because the coating is long-lasting and resistant to wear, powder-coated outdoor furniture requires minimal upkeep. Routine cleaning requires only mild soap and water, while repainting or sealing is rarely necessary. This low-maintenance design is particularly advantageous for hospitality venues, resorts, and public spaces where reducing upkeep directly lowers operational costs and ensures reliable performance for clients.

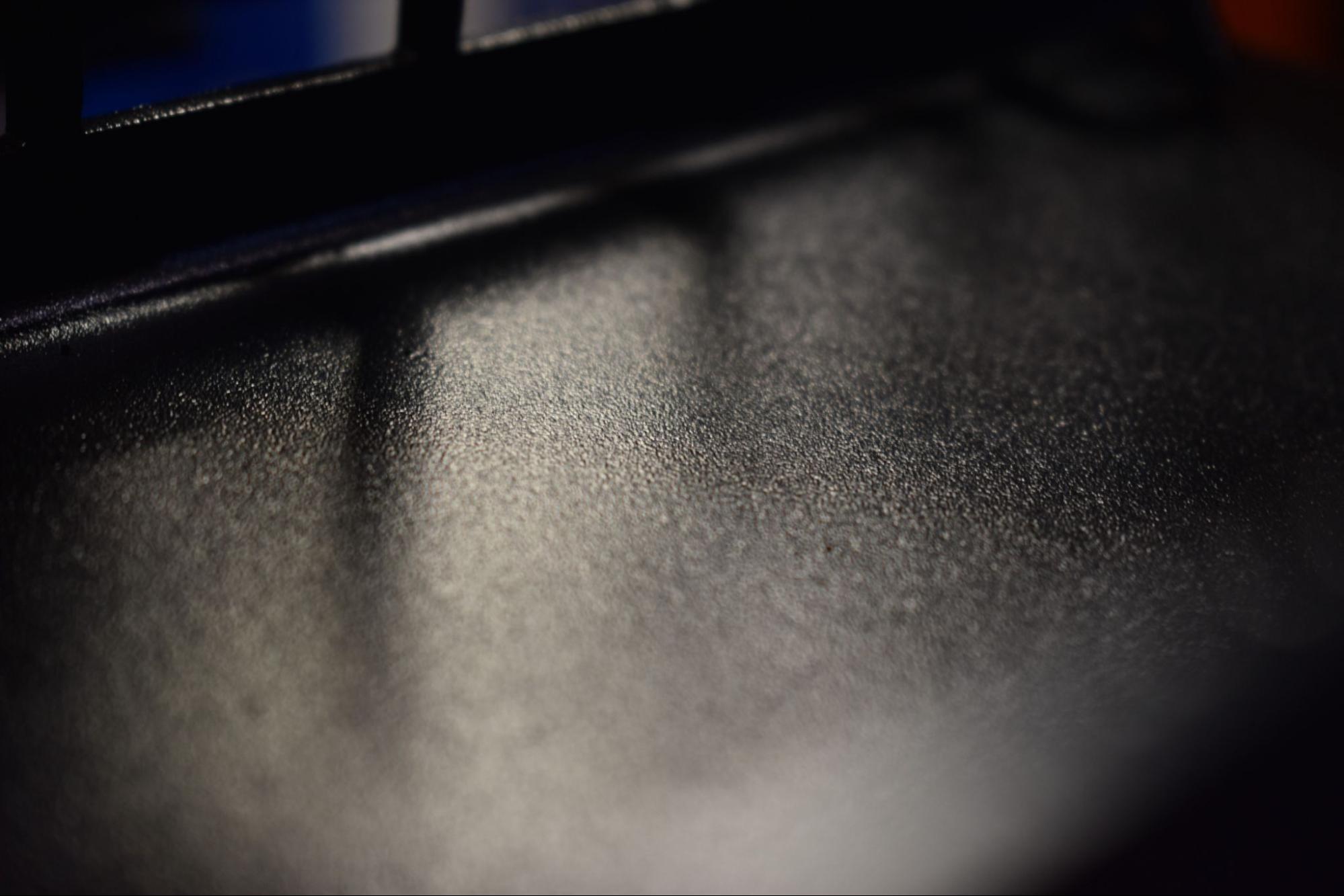

Long-lasting colour and surface performance

Powder coating creates a dense, UV-resistant finish that helps outdoor furniture retain its original colour and appearance even under prolonged sun exposure. The hardened surface also provides strong scratch and abrasion resistance, reducing visible wear during frequent use. These combined properties extend the overall service life of powder-coated furniture, offering B2B buyers lower maintenance needs and more reliable long-term performance.

Stylish and versatile design options

The powder coating process supports a wide range of finishes, including matte, gloss, and textured surfaces. EU projects can select from an extensive palette of RAL colour codes, enabling modern, classic, or resort-style designs tailored to each space.

Environmentally sustainable choice

Powder coating is VOC-free, reducing harmful emissions, and its recyclable overspray minimises material waste. This makes powder-coated outdoor furniture a responsible choice that aligns with ESG commitments and procurement standards in the EU

Things to consider before choosing powder-coated outdoor furniture

Before investing in powder-coated outdoor furniture, it’s important to evaluate a few practical factors that influence performance, lifespan, and overall value, especially for commercial or large-scale projects.

Initial investment vs long-term ROI

Powder-coated outdoor furniture typically comes with a higher upfront cost compared to basic painted options. However, its extended durability and low maintenance needs significantly reduce long-term expenses, resulting in a stronger overall return on investment.

Surface integrity and repair

Although powder coating is highly durable, the surface can still chip if exposed to strong impact. Small imperfections can be repaired using touch-up kits, while larger damage requires factory-level recoating to restore full protection and appearance.

Heat retention in direct sunlight

Darker powder-coated finishes may absorb more heat when placed outdoors. This can be easily managed by opting for lighter shades, adding cushions, or incorporating shading structures into the outdoor layout.

Choosing the right manufacturer

Selecting a powder-coated outdoor furniture manufacturer that utilises fully automated, advanced systems is critical for B2B enterprises. This ensures that products achieve optimal adhesion, corrosion resistance, and process consistency. Facilities with precision-controlled coating lines and regulated curing environments deliver uniform coating thickness, high surface integrity, and export-grade durability and aesthetics, making them a reliable partner for businesses supplying regional and global markets.

Maintenance tips for longevity

To maximise the lifespan of powder-coated outdoor furniture, a few simple maintenance practices can help preserve both its appearance and protective performance:

- Regular cleaning using mild soap and water to remove dust, dirt, and environmental buildup.

- Seasonal protection, such as applying optional wax or protective sprays, to enhance surface resistance throughout the year.

- Use breathable covers or store furniture indoors during harsh winter conditions to prevent unnecessary exposure to moisture and freezing temperatures.

- Touch-up kits can be applied to minor scratches or chips to stop corrosion from forming and maintain the integrity of the coating over time.

Popular applications of powder-coated outdoor furniture

Powder-coated outdoor furniture is widely adopted across residential, commercial, and hospitality environments due to its durability, aesthetic flexibility, and ability to perform reliably in various climates. Below are the most common applications, with additional detail on how each setting benefits from powder coating.

Outdoor dining sets for gardens, cafés, and patios

Powder-coated dining tables and chairs are ideal for outdoor dining areas where furniture must handle constant use and weather exposure.

They resist rain, moisture, and UV rays, making them suitable for cafés, restaurants, and home patios that require stable, long-lasting seating. The wide colour and finish options also help businesses align furniture with branding or design themes.

Lounge seating and modular sofa systems for hotels and resorts

Hotels and resorts rely on furniture that can maintain both comfort and visual appeal despite continuous outdoor exposure.

Powder-coated metal frames provide structural stability for lounge chairs, modular sofas, side tables, and daybeds, while their weather-resistant coating ensures the furniture retain their colour and finish. This helps hospitality operators reduce maintenance time and replacement frequency.

Sun loungers, benches, and poolside furniture

Poolside environments expose furniture to constant sun, high humidity, and occasional contact with chlorine or saltwater, demanding materials that can withstand these harsh conditions. Powder-coated outdoor furniture meets these requirements, providing fade resistance, corrosion protection, and a smooth, easy-to-clean surface. These properties make it an ideal and practical choice for public pools, beachfront resorts, and private villas.

Custom OEM designs for villas, resorts, and large hospitality projects

For large-scale developments or premium residential projects, powder coating supports fully customised OEM outdoor furniture tailored to specific design requirements.

Developers can choose from extensive RAL colours, textures, and frame structures to match architectural concepts, whether modern minimalist, tropical resort-style, or classic European designs. The durability of powder-coated metal ensures these bespoke pieces maintain consistent quality throughout the project’s lifecycle.

Why choose THACO INDUSTRIES for powder-coated outdoor furniture?

As one of Vietnam’s leading industrial manufacturers, THACO INDUSTRIES delivers end-to-end OEM solutions for global partners seeking durable, high-quality finishing and export-ready powder-coated outdoor furniture. With large-scale production capabilities and a dedicated R&D center equipped with the modern laboratory, simulation tools, and multidisciplinary engineering expertise, the corporation ensures consistency, reliability, and long-term value for B2B buyers across Europe, Australia, and North America.

Key advantages of working with THACO INDUSTRIES

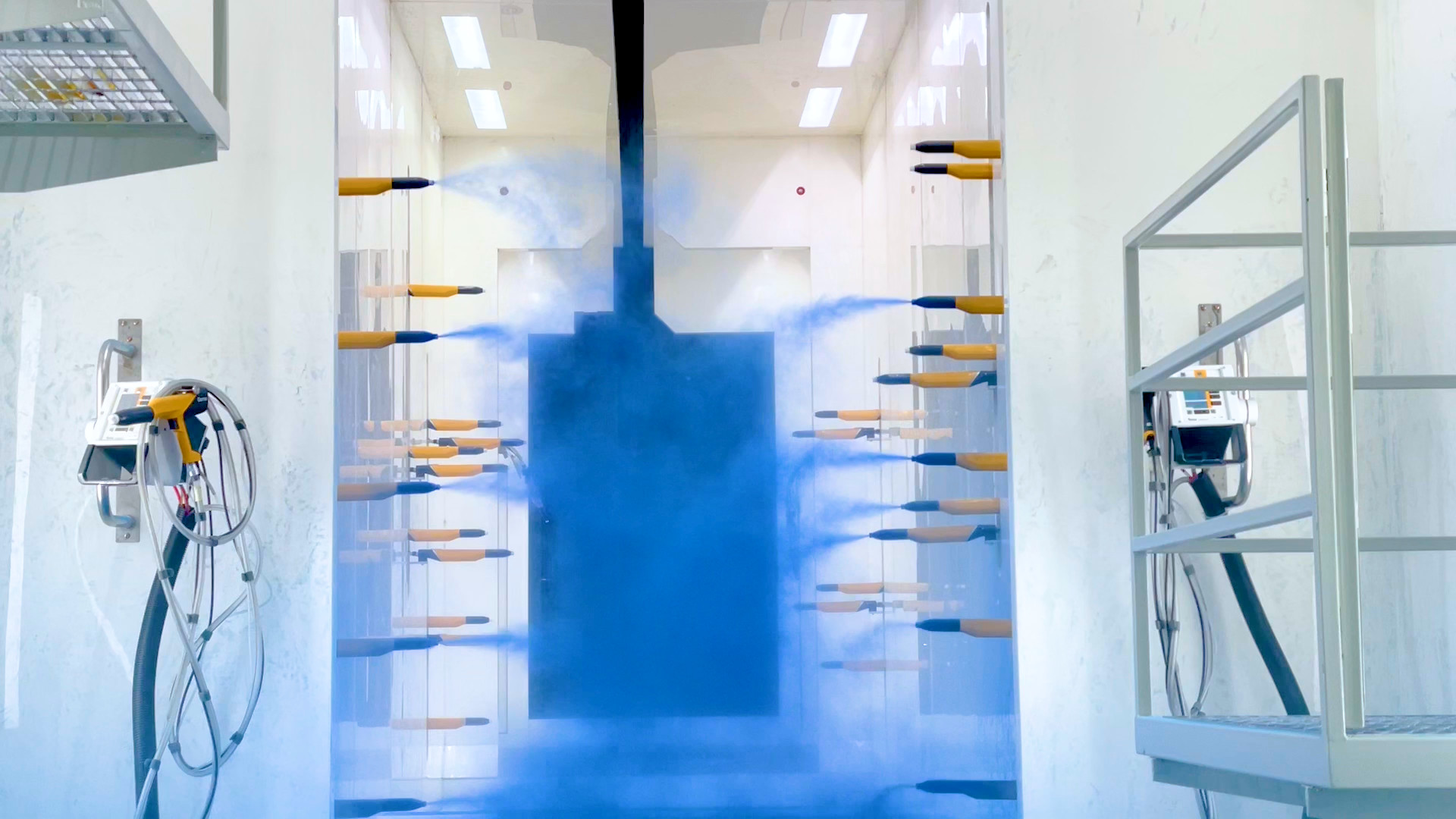

In-house powder coating facilities

THACO INDUSTRIES operates its own automated powder coating lines, enabling controlled surface preparation, stable quality, and consistent finishing across every batch. This ensures efficiency, uniformity, and scalable production for high-volume or project-based orders.

Large industrial manufacturing plants

With a well-established industrial manufacturing system and multiple specialised production plants, THACO INDUSTRIES is well positioned to support the supply requirements of European distributors, hospitality developers, and global outdoor furniture brands. Its integrated manufacturing model enables stable output, controlled production scheduling, and dependable lead times, even for high-volume OEM/ODM orders. This cross-sector production capability reflects the corporation’s capacity to manage complex contracts and support global distribution with consistent quality and delivery performance.

Integrated production line – a complete OEM solution

From material sourcing, metal fabrication, and machining to powder coating, assembly, testing, and packaging, THACO INDUSTRIES provides a fully integrated manufacturing ecosystem. This one-stop approach enhances product synchronisation, reduces costs, and simplifies supply chain management for international clients.

Strong commitment to sustainability and quality assurance

The corporation’s manufacturing processes align with European ESG expectations, emphasising eco-friendly finishing and responsible material handling. Environmental and quality controls are maintained to meet strict global export standards.

Cost-efficient B2B pricing

Thanks to large-scale operations, optimised supply chains, and in-house finishing capacity, THACO INDUSTRIES offers competitive pricing that supports distributors, wholesalers, and project developers seeking long-term value.

Internationally certified production quality

Quality remains the highest priority. Every production stage is governed by:

-

- ISO 9001:2015 – Quality Management System

- IATF 16949:2016 – Automotive sector-level precision for metal parts

- ISO 14001:2015 – Environmental Management System

These certifications ensure reliable finishing quality, dimensional consistency, and environmental responsibility.

Commitment to high-end finishing and aesthetic standards

THACO INDUSTRIES is dedicated to delivering powder-coated outdoor furniture that meets demanding international requirements for visual appeal, coating uniformity, and long-term durability, providing partners with products that perform exceptionally well in both residential and commercial outdoor settings.

FAQs

How long does powder-coated aluminium furniture last outdoors?

Typically, powder-coated aluminium furniture can last 10 – 15 years with proper care and maintenance.

Is powder-coated furniture completely rust-proof?

- Aluminium frames are naturally rust-proof.

- Steel frames are highly resistant to corrosion, but minor touch-ups may be needed if the coating is chipped or damaged.

Where do I buy powdered outdoor furniture?

For high-quality, durable, and export-ready powder-coated outdoor furniture, contact THACO INDUSTRIES. The corporation offers OEM/ODM solutions, scalable production, and reliable delivery for B2B clients worldwide.

Powder-coated outdoor furniture combines durability, low maintenance, and versatile design, making it an ideal choice for commercial and residential projects alike. With THACO INDUSTRIES as your trusted partner, you gain access to advanced manufacturing, in-house powder coating facilities, and strict quality control, ensuring products that meet international standards and perform reliably in any outdoor environment.

For inquiries or to discuss OEM/ODM solutions, contact THACO INDUSTRIES via email: partsales@thaco.com.vn or hotline: +84 348 620 063. Let us help you deliver long-lasting, high-quality outdoor furniture to your projects.