COMMERCIAL & HOUSEHOLD PRODUCTS MANUFACTURER

THACO INDUSTRIES’ commercial & household products not only serve the domestic market effectively but are also exported to multiple countries, including the USA, Canada, Australia, Japan, and South Korea.

Fitness Equipment Manufacturing

Civil Material Handling Equipment Manufacturing

Home Appliances Manufacturing

Home Decor & Housewares Manufacturing

Decorative & Utility Products

MANUFACTURING PROCESS

Customer Requirement & Project Definition

THACO INDUSTRIES works with OEM/ODM partners to define specifications, quality standards, branding, and target markets, then aligns scope, cost, and timeline within its closed-loop value chain, creating a clear foundation before engineering and manufacturing begin.

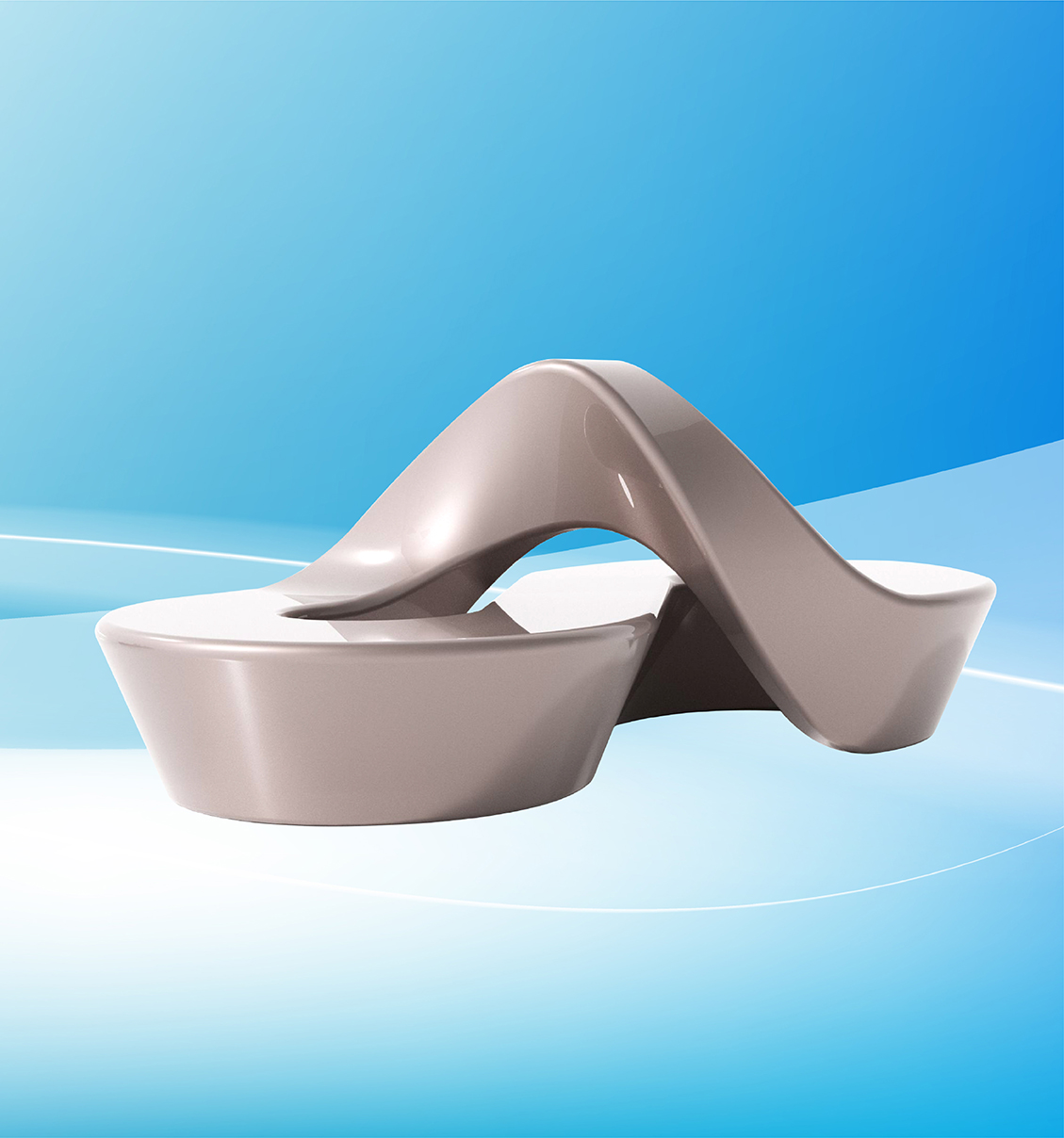

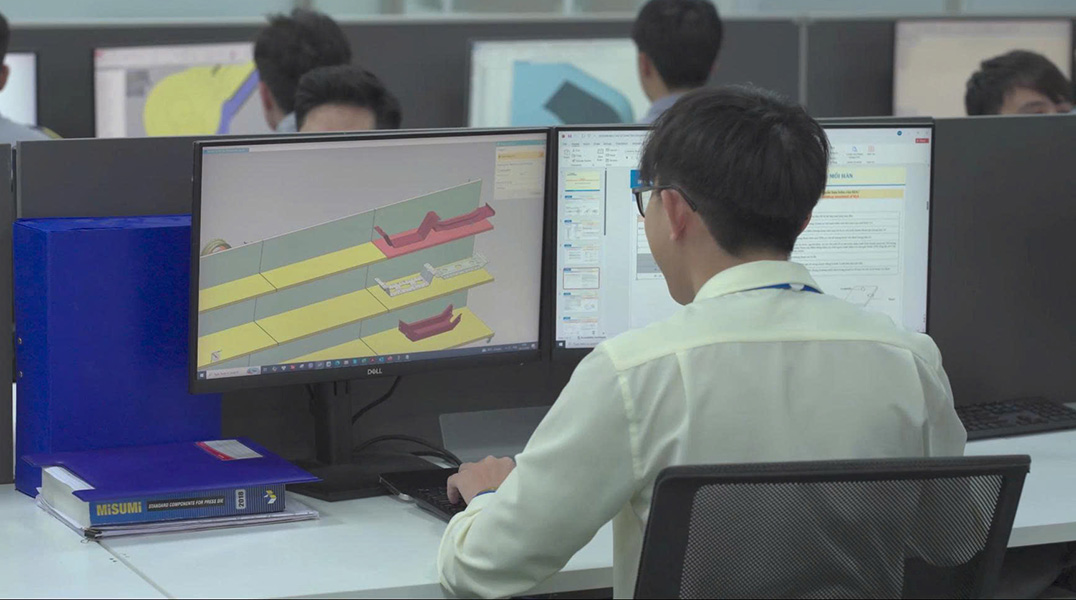

Concept Design & Engineering

R&D engineers develop concepts, 3D models, and engineering calculations, evaluating manufacturability and structural integrity so products fit THACO INDUSTRIES’s industrial processes while meeting customer performance and certification requirements.

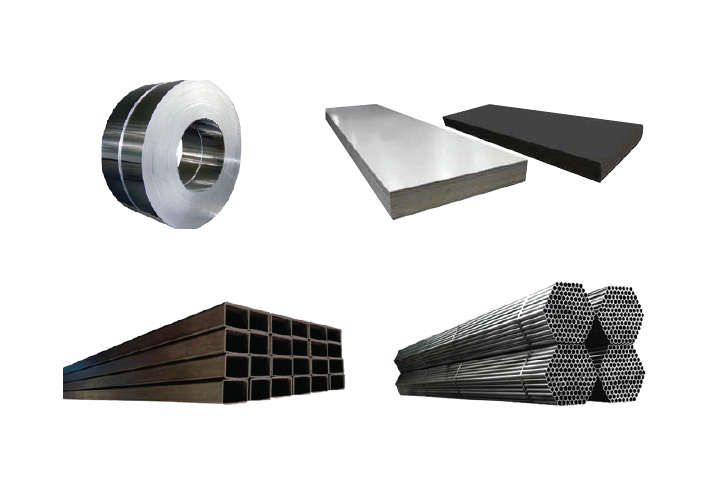

Material & Component Planning

Engineers select suitable metals, plastics, and standard components, define internal versus outsourced parts, and finalize the Bill of Materials, leveraging THACO INDUSTRIES’ large-scale steel, plastic, and component-manufacturing capacities to support consistent, scalable OEM/ODM production.

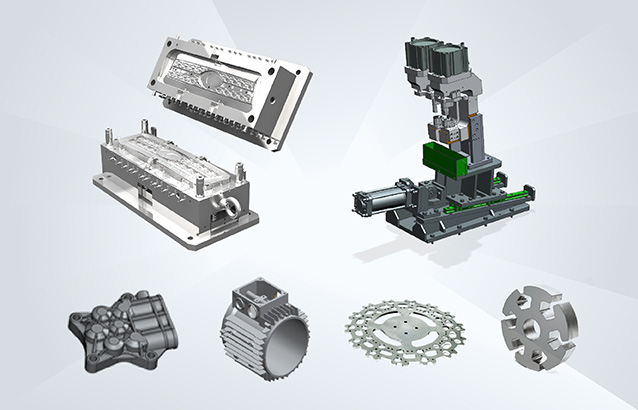

Tooling & Fixture Preparation

THACO INDUSTRIES’ Mold Company produces molds, dies, jigs, and fixtures, then validates them through trials, ensuring dimensional accuracy and repeatability for mass production across automotive, industrial, agricultural, and household sectors.

Primary Processing

Steel, aluminum, and plastic parts are produced through cutting, stamping, machining, tube-forming, and molding processes, using modern equipment at the Mechanical Center and plastics plants to deliver accurate structural and aesthetic components.

Welding & Structural Fabrication

Frames, structures, and subframes are welded using both robotic and manual lines with dedicated jigs, ensuring high repeatability and strength for equipment and consumer products prior to finishing.

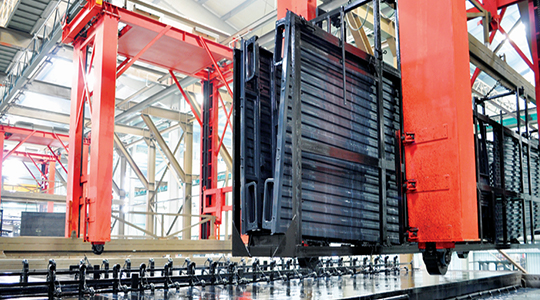

Surface Preparation & Finishing

Shot-blasting, ED coating, powder coating, and other finishes are applied to enhance corrosion resistance, durability, and appearance, validated by salt-spray and related tests for demanding export markets.

Sub-Assembly & Assembly

THACO INDUSTRIES combines mechanical, plastic, and customer-specified components into modules or finished products, using integrated assembly lines that support flexible, scalable manufacture and assembly of parts for diverse OEM programs.

Quality Control & Testing

Dimensional, mechanical, functional, and durability tests are performed under ISO 9001 and ISO 17025 frameworks in THACO INDUSTRIES’ laboratories and inspection systems, ensuring consistent compliance with technical standards and customer specifications.

Packaging & Logistics

Products are packaged and prepared for domestic or export shipping, leveraging THACO INDUSTRIES’ logistics and global OEM supply network to deliver safely to nearly 30 countries and many demanding markets.

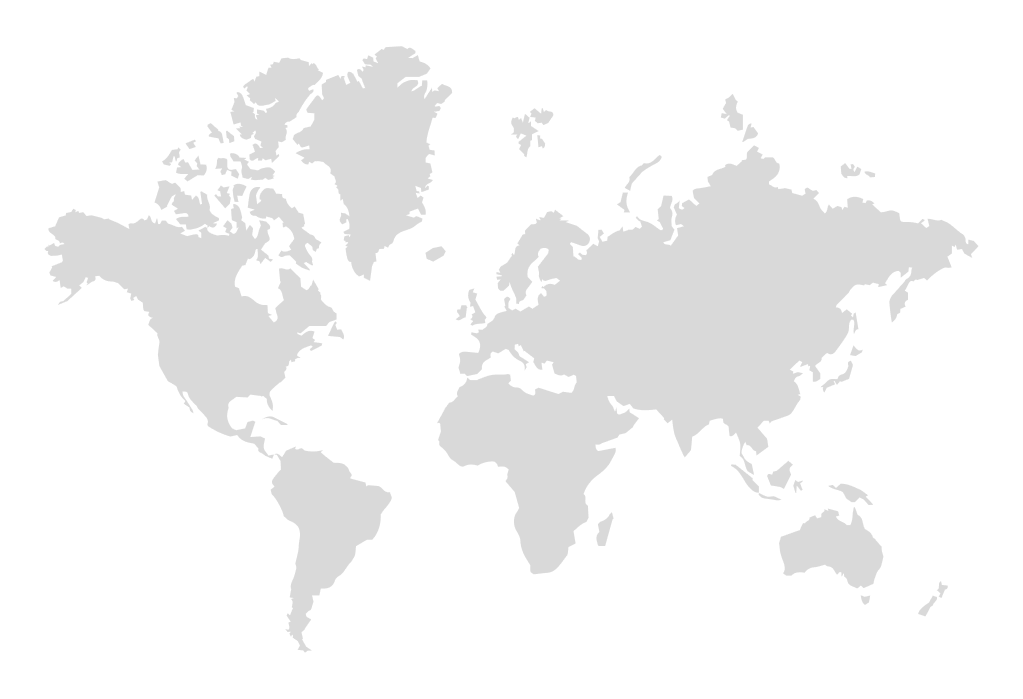

OUR MARKETS

-

North America

-

EU

-

Asia

FAQs

Do you support complete end-to-end product manufacturing, or only structural/mechanical parts?

Can you customize machines or consumer products based on my brand standards and regulatory requirements?

Do you offer full ODM design services, or do I need to provide detailed CAD models?

Can you support multi-destination exports for different markets?

How do you ensure compliance with different markets (US, EU, Australia, Japan)?

WHY PARTNER WITH THACO INDUSTRIES

THACO INDUSTRIES is a strategic OEM/ODM partner with large-scale, end-to-end manufacturing capabilities across commercial and household product categories. Its production scope covers fitness equipment, home appliances, decor and utility products.

Advanced mechanical processing, plastic injection molding, welding, automated coating, and assembly capabilities enable THACO INDUSTRIES to develop customized products while ensuring durability, quality, and visual consistency. The closed-loop manufacturing process, from R&D, Processing, Welding, Surface Treatment & Painting and Assembly that meets technical and export standards for markets such as the US, Canada, Australia, Japan, and South Korea.

With stringent quality control systems and optimized DFM practices, THACO INDUSTRIES shortens time-to-market and ensures full customer confidentiality throughout each project.