AGRICULTURAL MACHINERY MANUFACTURER

Cultivation Equipment Manufacturing

Processing Equipment Manufacturing

Livestock Equipment Manufacturing

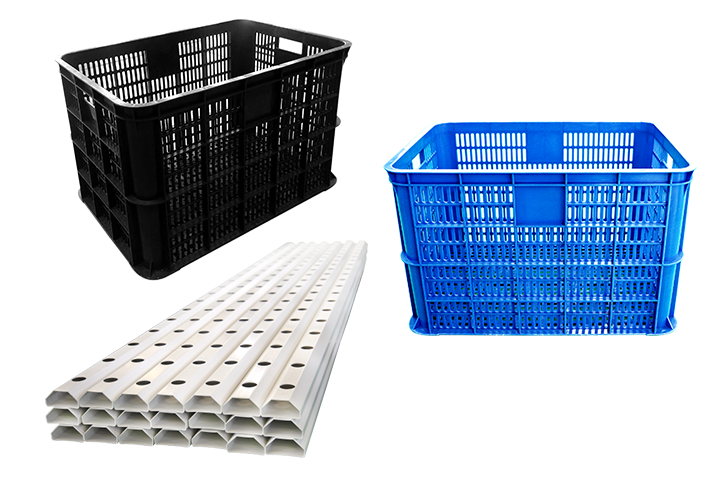

Agricultural Plastic Components

MANUFACTURING PROCESS

Market Research Product Definition

THACO INDUSTRIES analyzes partner requirements, farm applications (livestock farming, land preparation, cultivation, harvesting, storage, processing, and packaging), and OEM/ODM specifications to define product functions, performance, and compliance targets for agricultural equipment and production lines.

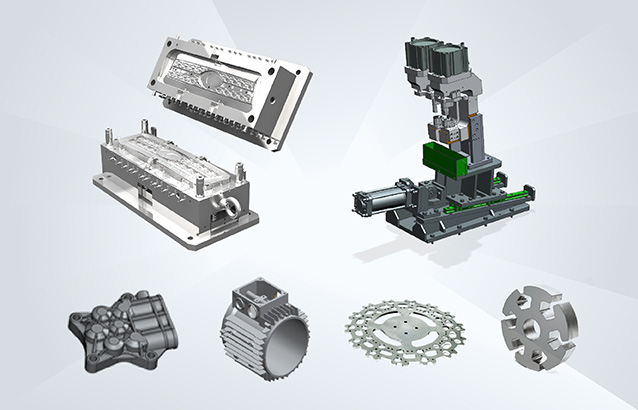

Engineering Design Simulation

R&D engineers develop 2D/3D designs, conduct structural calculations and process layouts, and use advanced design and simulation tools within THACO INDUSTRIES’ R&D center and Mechanical center to optimize feasibility, durability, and operational efficiency for agricultural equipment.

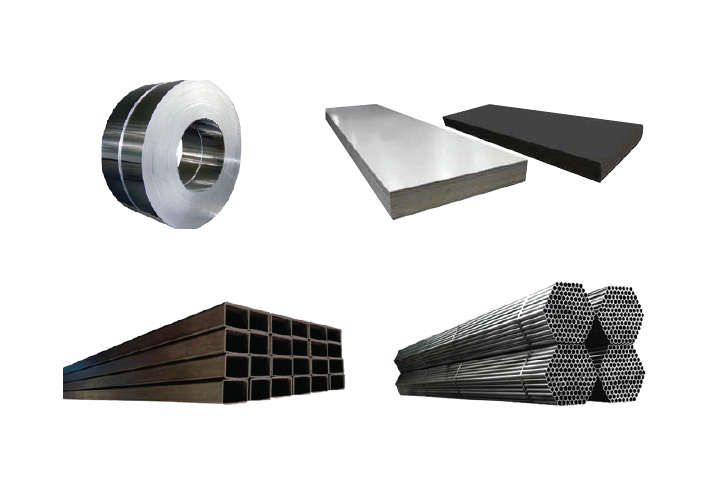

Material Planning Procurement

Based on approved designs, THACO INDUSTRIES plans and procures materials including steel, non-ferrous metals, plastics, and standard components through an integrated supply chain, ensuring international-standard materials, traceability, and cost optimization for project- and product-based agricultural orders.

Billet / Workpiece Processing

Raw materials are prepared at the Mechanical Center using advanced technology lines, including slitting lines, box & tube lines, fiber laser cutting, CNC plasma/oxy-gas cutting, and related systems, forming the base frames, structures, and parts for agricultural machinery and equipment.

Forming Precision Machining

Processed billets undergo forming (press braking, stamping, rolling, flange forming) and precision machining (CNC milling, turning, drilling, and grinding) to achieve the dimensions and tolerances specified in technical drawings for agricultural components, modules, and mounting structures.

Welding Structural Fabrication

Welding is carried out using both manual and robotic welding lines, applying certified welding quality systems to ensure consistent strength, precision, and reliability for heavy steel structures and mechanical products.

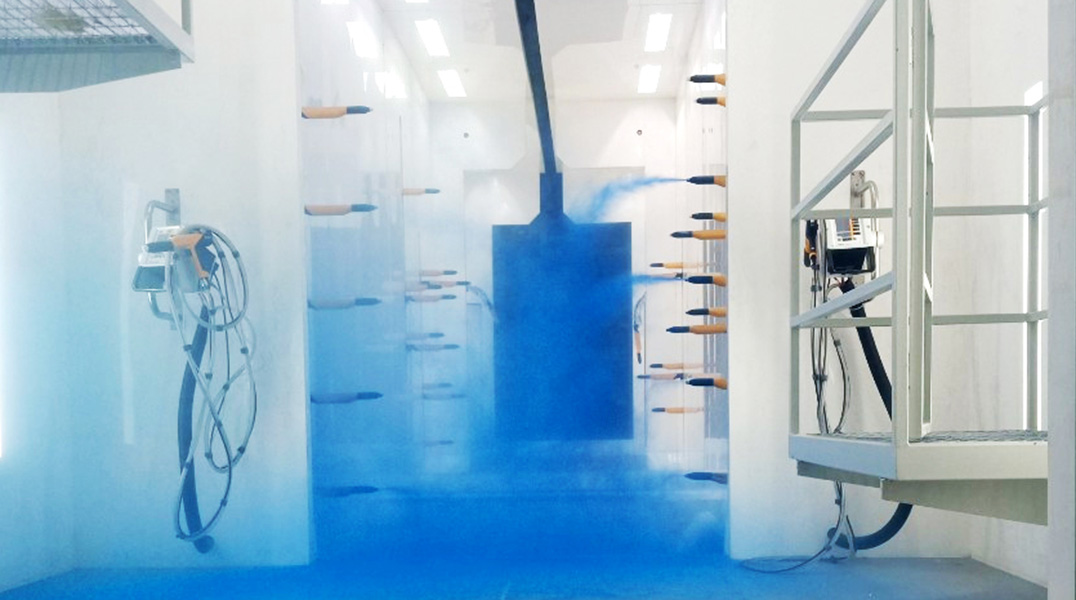

Surface Treatment Painting

Fabricated structures undergo surface preparation, shot blasting, anti-corrosion treatment, and ED or powder coating, ensuring durability in harsh agricultural and outdoor environments.

Mechanical, Electrical Hydraulic Assembly

Coated parts move to assembly, where mechanical structures are integrated with drives, hydraulics, pneumatics, and electrical/control systems into complete machines, line modules, or farm systems, customized to project and OEM/ODM requirements for cultivation, processing, livestock, and waste-related solutions.

Quality Control Testing

Throughout production, THACO INDUSTRIES applies multi-step QC under ISO 9001:2015, ISO 14001:2015, EN 1090, and ISO 3834, including dimensional checks, functional tests, and performance validation to ensure export-quality agricultural machinery and equipment in compliance with international market requirements.

Packaging, Logistics Delivery

Finished equipment and lines are packaged, documented, and shipped using a process explicitly defined from “processing, surface treatment – painting, assembly, packaging, transportation” for mechanical products, applied consistently to agricultural machinery for both domestic and export markets.

CERTIFICATIONS

THACO INDUSTRIES has obtained certifications of ISO 9001:2015, and the Environmental Management System ISO 14001:2015. The products meet the stringent standards of both domestic and export customers.

OUR MARKETS

-

European

-

ASEAN

-

NORTH AMERICA

FAQS

Can THACO INDUSTRIES act as an OEM or ODM for agricultural equipment for other brands?

What stages of the agriculture value chain does THACO INDUSTRIES cover?

Which agricultural machinery and equipment solutions does THACO INDUSTRIES supply to partners in the United States, Canada, and Mexico?

Can THACO INDUSTRIES provide OEM/ODM confidentiality, IP protection, and long-term development support?

Can THACO INDUSTRIES handle complete turnkey agricultural projects instead of only equipment manufacturing?

WHY PARTNER WITH THACO INDUSTRIES

OEM and ODM partners choose THACO INDUSTRIES for agricultural equipment because we provide a fully integrated “all-in-one” manufacturing ecosystem. THACO INDUSTRIES establishes a comprehensive, closed-loop operational value chain encompassing market research, product research, new materials research, engineering design, simulation, prototyping, testing, and final product refinement. Each stage is tightly controlled, significantly shortening the research and development time while promoting rapid and precise improvements.

We manufacture solutions for cultivation, harvesting, post-harvest processing, livestock farming, and waste-treatment systems, giving partners a single, scalable source for diverse agricultural machinery. Our operations comply with international standards, including ISO 9001:2015, ISO 14001:2015, EN 1090, and ISO 3834, meeting global expectations for durability, safety, and traceability.

With a dedicated R&D Center, we support co-engineering, new product development and customized specifications while maintaining strict intellectual-property protection for partner technologies. In addition, we provide turnkey capability for complete production lines and integrated farm systems. These strengths reinforce THACO INDUSTRIES’ position as a dependable long-term OEM/ODM partner for agricultural equipment in global markets.