Product information

Excavator Bucket Manufacturers and How to Choose Right One

In heavy-duty operations such as construction, mining, and quarrying, excavator buckets have a direct impact on machine productivity and operational efficiency, influencing how effectively equipment performs digging, lifting, and material handling tasks. Their performance is shaped not only by design but also by the engineering precision and manufacturing quality behind them, making the choice of excavator bucket manufacturers more important.

In this article, THACO INDUSTRIES shares key insights on evaluating bucket manufacturers, understanding the technologies that enhance durability, and selecting the right partner for long-term operational demands.

Understanding Excavator Buckets and Their Uses

What is an Excavator Bucket?

Excavator buckets are primary work attachments engineered to dig, load, grade, and handle a wide range of materials across earthmoving, quarrying, demolition, and mining operations. As structural components subjected to continuous impact, abrasion, and high breakout forces, buckets must be designed with precise geometry, high-strength materials, and reinforced wear zones to maintain efficiency in demanding environments.

Excavator Bucket Types

Excavator buckets are engineered in different designs to match material characteristics, operating conditions, and productivity requirements. Common bucket types include:

General-purpose buckets

Designed for everyday excavation and material handling, general-purpose buckets are suitable for soil, clay, sand, and light aggregates. They feature a balanced structure with standard wear protection, offering good digging efficiency and versatility across construction and utility projects.

Heavy-duty buckets

Heavy-duty buckets are reinforced with thicker plates, wear strips, and stronger cutting edges to withstand abrasive materials and harsh working conditions. They are commonly used for compacted soil, mixed materials, and moderately rocky environments where higher impact resistance and longer service life are required.

Rock buckets

Built for extreme-duty applications, rock buckets feature heavy reinforcement, wear-resistant steel, and often include rock ribs or teeth with enhanced penetration. These buckets are designed for quarrying, mining, and hard rock excavation, ensuring durability under high-impact and high-abrasion conditions.

Tilt buckets

Tilt buckets are equipped with hydraulic tilting mechanisms that allow angular adjustment without repositioning the excavator. They are ideal for grading, slope shaping, ditch cleaning, and finishing work, improving accuracy and reducing cycle time on landscaping and infrastructure projects.

Clamshell buckets

Clamshell buckets consist of two hinged shells that open and close vertically, making them suitable for deep excavation, material handling in confined spaces, and dredging operations. They are commonly used in foundation work, port construction, and bulk material handling where vertical digging or precise placement is required.

Uses of excavator buckets

Depending on bucket design and application, excavator buckets are used across a wide range of earthmoving and material-handling tasks, including:

- Digging trenches, foundations, and utility lines

- Loading and transporting soil, sand, aggregates, and gravel

- Breaking and handling rock in quarry or mining operations

- Sloping, grading, and site-finishing tasks

- Handling construction debris or bulk materials in demolition sites

High-quality excavator buckets play a decisive role in operational performance. Durable structures reduce wear, minimize downtime, and extend the lifecycle of the machine’s front attachment system. Properly engineered buckets also enhance digging efficiency, optimize breakout force, reduce fuel consumption, and lower overall maintenance costs, factors that directly influence productivity and long-term return on investment for contractors and equipment owners.

Key Criteria to Evaluate Excavator Bucket Manufacturers

Choosing the right excavator bucket manufacturer requires a thorough understanding of the engineering quality, durability, and production standards behind each bucket. Evaluating these factors helps ensure the attachment performs reliably in challenging environments such as construction sites, mining areas, or demolition projects.

Material Quality & Steel Grade

High-performance buckets depend on premium materials such as Hardox wear plate, quenched-and-tempered (Q&T) steel, and other abrasion-resistant alloys. These materials provide excellent hardness, impact resistance, and structural stability, helping the bucket withstand continuous digging and heavy-loading cycles without bending, cracking, or premature wear.

Welding Technology and Structural Reinforcement

Advanced welding techniques greatly influence bucket longevity. Robotic welding, full-penetration welds, and optimized bead placement ensure consistent structural strength. Additionally, reinforced gussets, side plates, and anti-crack design elements keep the bucket durable even in demanding rock or quarry applications.

Design Capabilities and Engineering Tools

Leading excavator bucket manufacturers use 3D modeling, FEA simulations, and digital engineering tools to refine bucket geometry, improve load distribution, and reduce stress concentrations. Custom-engineered bucket profiles – including capacity, tooth configuration, and cutting edges, help match the bucket to specific soil types, material density, and excavator tonnage.

Surface Finishing and Wear Protection

Quality surface finishing also contributes to service life. Manufacturers apply abrasion-resistant coatings, hardness treatment on cutting edges, and optional wear packages (side wear plates, shrouds, lip guards) protect against abrasion and repeated impact. A well-finished surface improves corrosion resistance, reduces friction during operation, and supports smoother digging efficiency.

Manufacturing Standards and Certifications to Look For

Choosing the right excavator bucket manufacturers requires looking beyond product appearance and assessing whether the producer follows internationally recognized standards that ensure mechanical integrity, welding precision, and suitability for harsh operating environments. Leading manufacturers implement a multi-layered compliance framework that covers materials, fabrication processes, weld quality, and export readiness.

Core International Certifications

- ISO 9001 (Quality Management System): Ensures consistent production processes with complete documentation, materials traceability, controlled non-conformities, and continuous improvement. This is critical for large-scale buyers who require stable quality across repeated orders.

- ISO 3834 (Welding Quality Requirements): A key standard for structural and heavy-duty equipment. It governs welding procedure qualification (WPQR), welder certifications, filler material control, heat input monitoring, and post-weld inspections. This certification is highly relevant for buckets exposed to extreme impact and abrasion.

- EN 1090 (EU Structural Steel Compliance): For manufacturers exporting to the EU, especially for excavator buckets or attachments used in construction and infrastructure. It validates load-bearing performance, weld quality, and welding compliance with European structural steel standards..

- CE Marking (European Market Compliance): Confirms that the excavator bucket meets EU safety, mechanical strength, and environmental requirements – necessary for distributors and OEM machinery dealers operating in the European market.

Advanced Testing & Inspection Processes

High-quality manufacturers employ comprehensive testing protocols to guarantee structural durability under real-world working conditions:

- Load & Static Testing: Simulates maximum operating conditions to validate structural stiffness, load capacity, and resistance to deformation.

- Fatigue Testing (Cycle Testing): Measures the lifespan of the bucket under repetitive digging, lifting, and prying forces – critical for mining and quarry applications.

- Impact & Abrasion Testing: Ensures the bucket material maintains its hardness and toughness when in contact with rocks, minerals, and high-friction environments.

- Hardness & Microstructure Testing: Confirms uniform hardness across wear plates, cutting edges, and side cutters to prevent premature wear.

- Ultrasonic & Magnetic Particle Weld Inspection: Detects internal and surface-level defects such as cracks, porosity, or incomplete fusion, ensuring weld integrity on high-stress joints.

- Dimensional Accuracy Inspection: Ensures bucket geometry, pin diameter, ear spacing, and mounting dimensions match OEM specifications for perfect machine fit.

Industry-Specific Compliance

Excavator buckets used in mining, construction, infrastructure development, demolition, and material handling must comply with additional sector requirements:

- Mining Standards: high wear resistance, reinforced ribs, corner protection, and validated weld strength for high-impact environments.

- Construction & Infrastructure: compliance with EU machine directive, CE marking, and EN standards for safety and operational integrity.

- OEM Machinery Integration: compatibility with machine brands through precise pin alignment, breakout force validation, and optimized bucket geometry.

THACO INDUSTRIES – Reliable Partner for Fabricated Excavator Buckets

As Vietnam’s leading OEM/ODM manufacturer in the mechanical engineering sector, THACO INDUSTRIES delivers end-to-end solutions for excavator buckets components including excavator buckets, arms, frames, and structural assemblies. Supported by an integrated production ecosystem and alignment with internationally recognized standards, the corporation serves as a reliable manufacturing partner for global machinery brands and industrial distributors.

THACO INDUSTRIES operates according to a closed-loop production process, including the following main stages:

Research & Development (R&D) → Fabrication → Welding → Surface Treatment & Painting → Assembly → Quality Control → Packaging → Logistics.

The entire production process is subject to strict quality control at every stage.

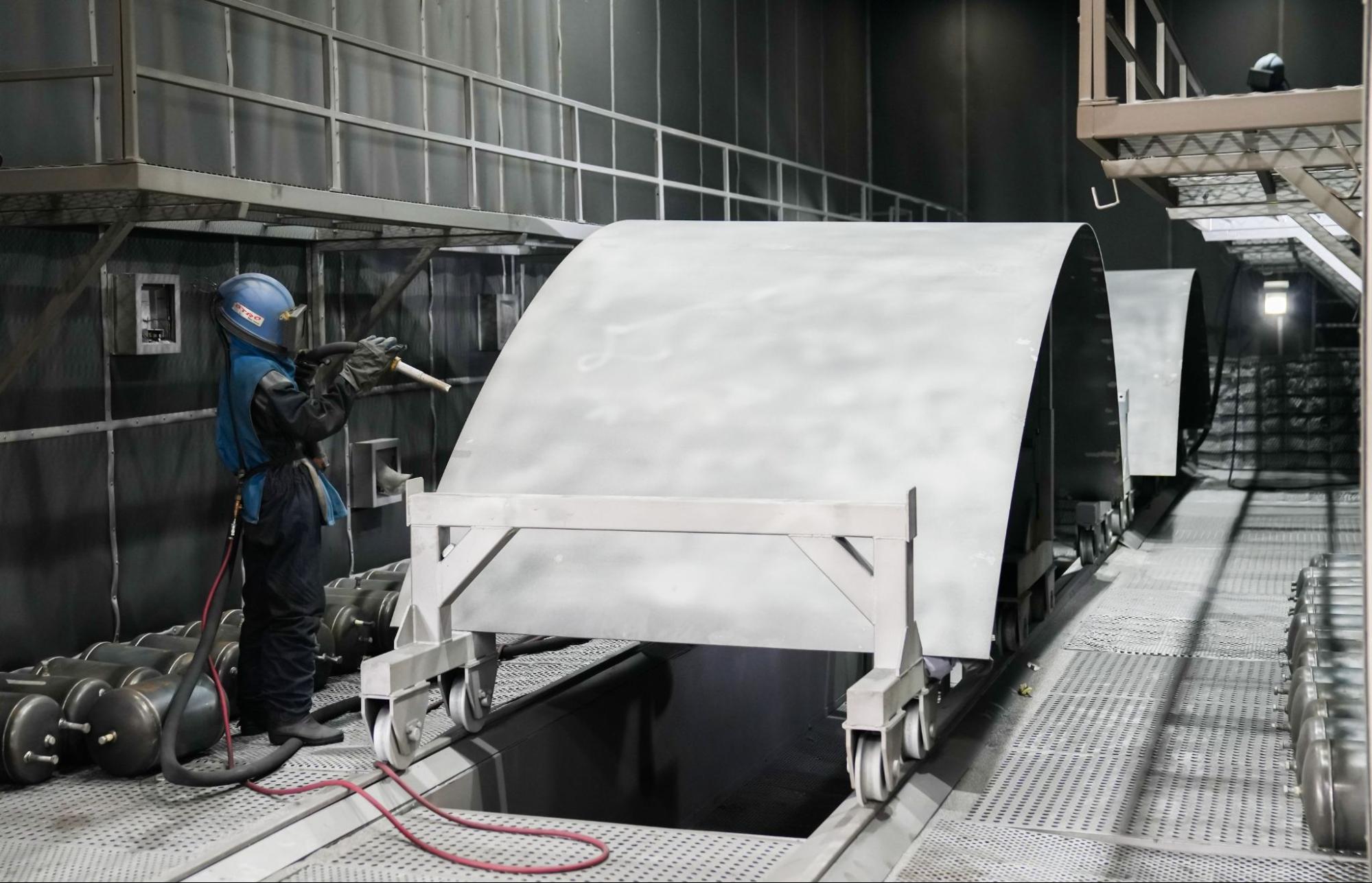

The corporation leverages advanced technologies such as CNC plasma cutting, robotic welding systems, and a modern surface-treatment & painting process including automatic shot blasting booth, ED coating, and powder coating. All welding work follows certified procedures, with welders qualified under AWS D1.1. This ensures strong joints, consistent penetration, and reliable structural performance. These qualities are essential for heavy-duty excavator buckets used in mining, quarrying, and construction environments.

Quality management is maintained through internationally recognized certifications, including ISO 9001:2015 and ISO 14001:2015, supported by comprehensive inspection processes such as hardness testing, dimensional verification, and weld integrity checks.

The corporation supports custom engineering, 3D design, prototyping, and mass production to accommodate OEM specifications ranging from bucket profiles and wear protection layouts to pin sizes and mounting configurations. With export capabilities spanning 30 countries, including major export markets such as the United States, Australia, Japan, and EU member states, THACO INDUSTRIES meets global standards. For tailored excavator bucket fabrication or OEM/ODM partnership inquiries, please contact THACO INDUSTRIES at partsales@thaco.com.vn or hotline +84 348 620 063.