Product information

Electrical Panel Manufacturing Company Standards & Process

Reliable electrical panels are a critical component of modern industrial systems, ensuring safe power distribution and stable system control. As an experienced electrical panel manufacturing company, THACO INDUSTRIES delivers customized, high-quality solutions for a wide range of industrial and infrastructure applications.

Introduction to Electrical Panel Manufacturing Companies

An electrical panel, commonly referred to as a switchgear or distribution board, is a core part of any electrical system. It manages how power is distributed, controlled, and protected within industrial plants, commercial buildings, and infrastructure projects. By housing circuit breakers, switches, and control devices in a single system, the panel helps ensure stable operation while reducing the risk of electrical faults and equipment damage.

Designing and manufacturing electrical panels requires more than basic assembly. Specialized electrical panel manufacturing companies must translate technical drawings, load calculations, and regulatory requirements into reliable, ready-to-install systems. As industries move toward higher automation levels, energy optimization, and stricter safety compliance, the need for well-engineered, consistently manufactured panels continues to increase across sectors such as manufacturing, renewable energy, data centers, and public infrastructure.

In practice, performance differences between panels often come down to the manufacturer’s engineering capability, production control, and quality standards. Working with an experienced and certified partner helps ensure electrical panels operate safely over the long term, remain compliant with international regulations, and perform reliably in demanding industrial environments.

Core Capabilities of a Professional Electrical Panel Manufacturing Company

A professional electrical panel manufacturing company combines deep engineering expertise with advanced manufacturing capabilities to deliver reliable and compliant power distribution panels and control panels

Engineering Expertise

- Development of detailed electrical schematics, load calculations, and wiring layouts

- Accurate panel sizing and configuration to match specific industrial or commercial requirements

- Simulation and testing to ensure safety, efficiency, and compliance with international standards

Manufacturing Capabilities

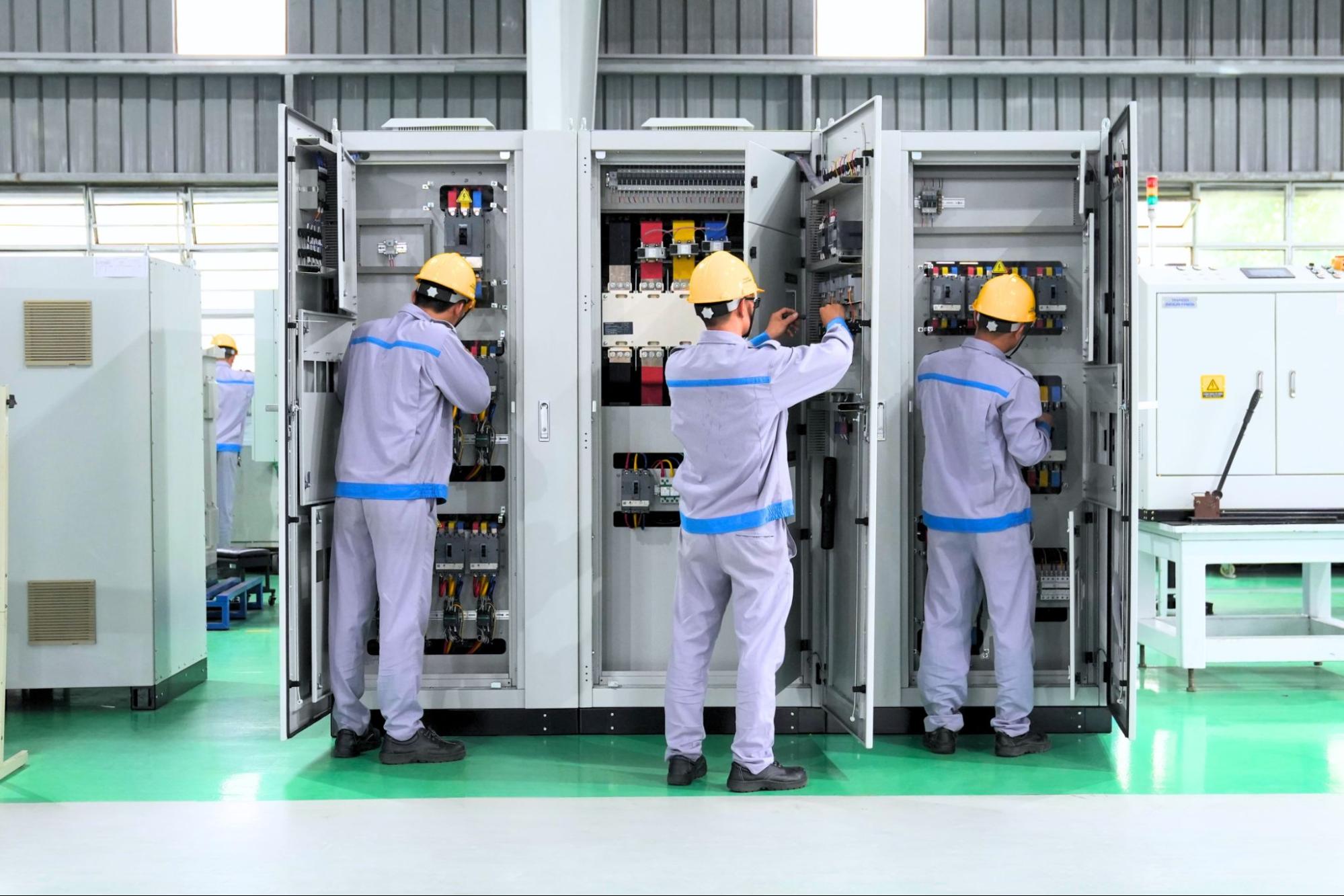

THACO INDUSTRIES delivers electrical panels through an integrated manufacturing system that ensures precision, consistency, and full compliance with international standards.

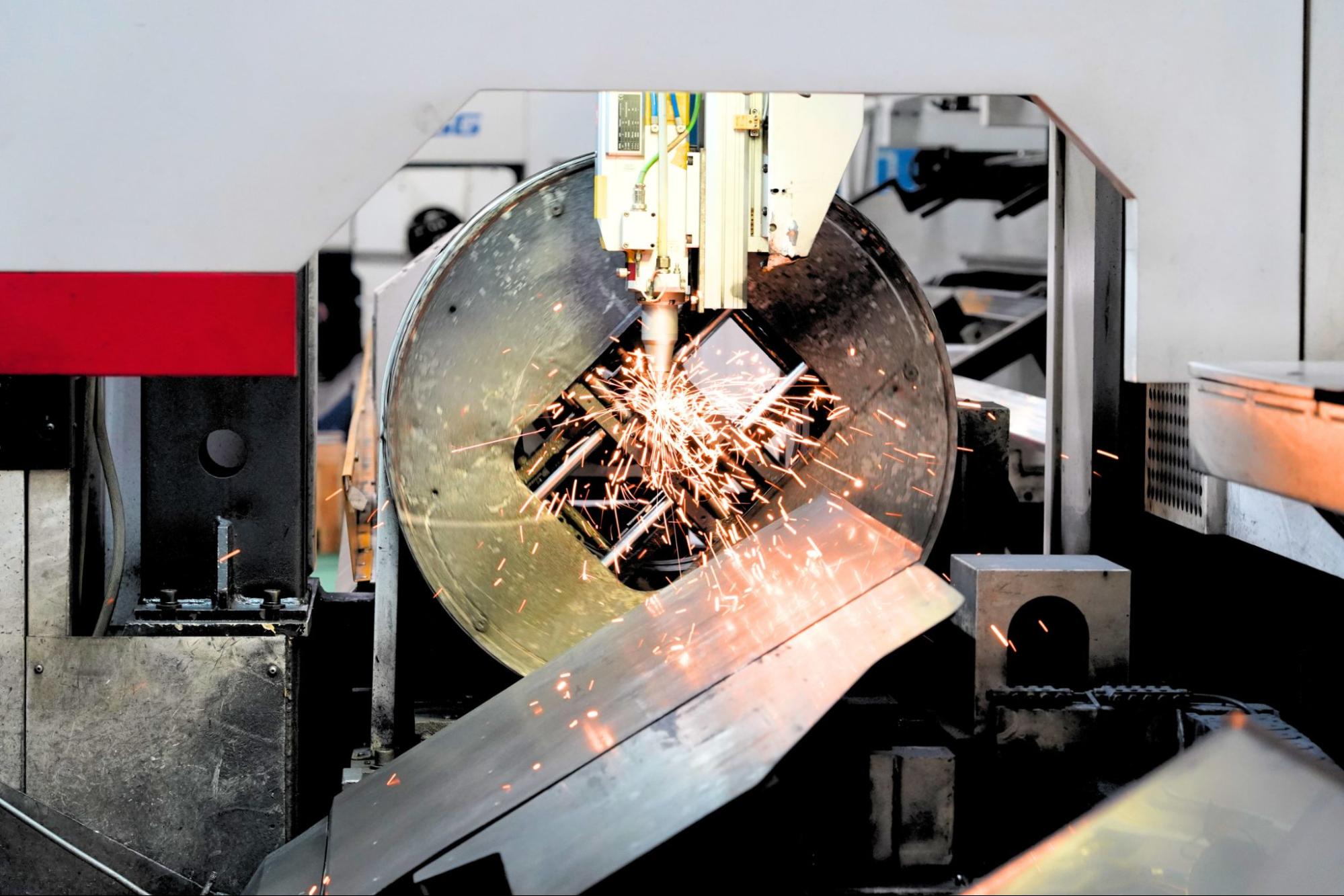

- Metal Fabrication: Panel enclosures and structural components are produced in-house through a controlled fabrication sequence, including slitting and shearing for raw material preparation, CNC laser cutting for dimensional accuracy, and stamping for repeatable component shaping. Advanced panel benders are used to form complex profiles with tight tolerances, while robotic welding and skilled manual welding ensure structural strength and uniform weld quality for both standard and customized designs.

- Surface Treatment: To enhance durability and corrosion resistance, fabricated parts undergo shot blasting for surface preparation, followed by ED coating for uniform coverage in concealed areas. Final powder coating is applied using automated lines with controlled curing parameters, delivering consistent thickness, strong adhesion, and long-term protection in demanding industrial environments.

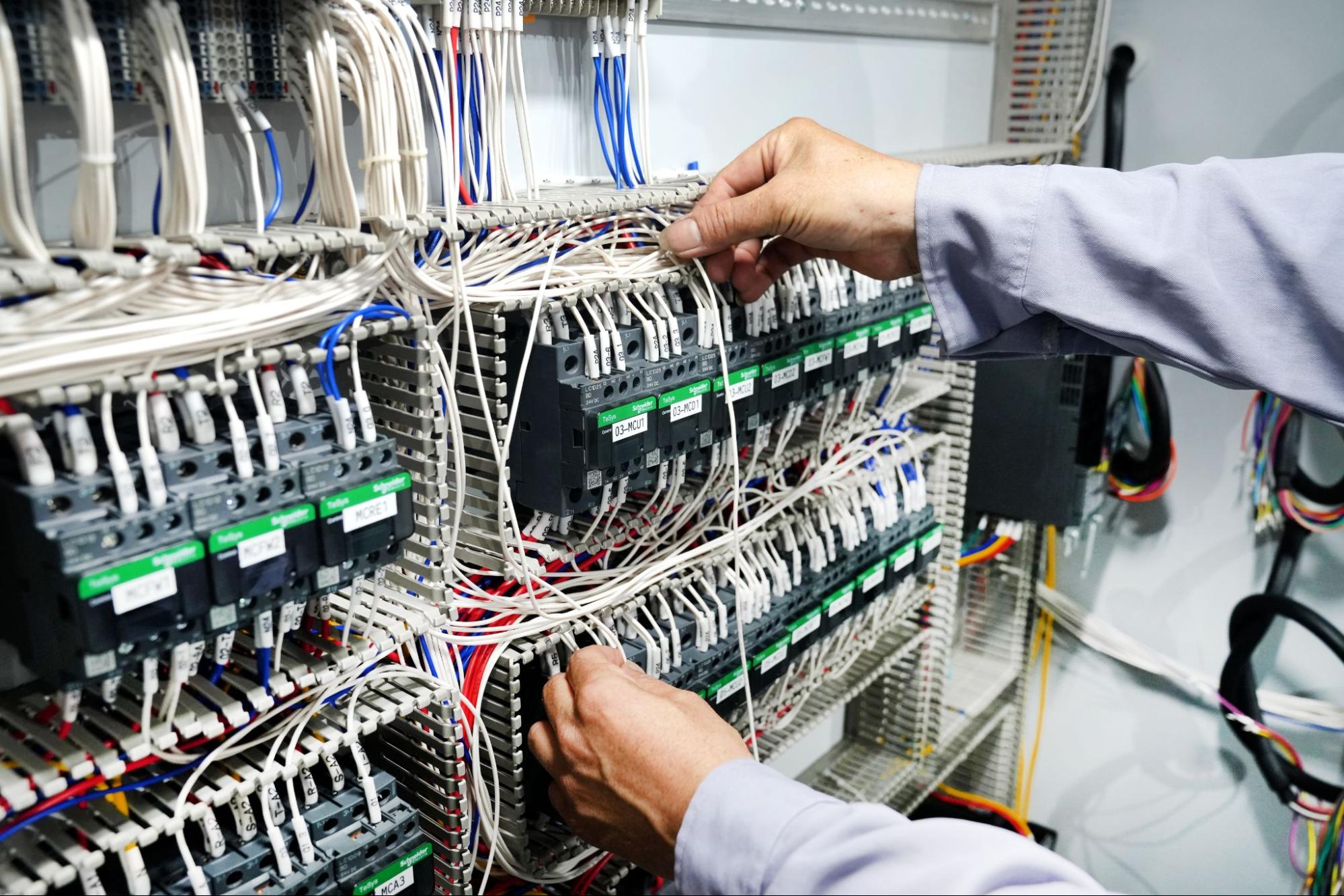

- Assembly and Integration: Assembly is carried out on dedicated lines, starting with component preparation and frame assembly. Copper busbars are precisely machined and assembled to ensure reliable current distribution. Certified electrical devices, including MCCBs, contactors, switchgear, and control components, are then installed in accordance with IEC and UL requirements. Electrical wiring is performed using standardized layouts and labeling for ease of maintenance and operational safety.

- Quality Control and Testing: Each electrical panel undergoes a comprehensive quality control process, covering material verification, in-process inspections, and final inspection. Electrical performance testing includes insulation resistance, continuity, and functional checks to validate safety and reliability. All procedures are conducted in compliance with IEC 61439 and THACO INDUSTRIES’ internal quality assurance protocols, ensuring full conformity before delivery.

Company-Level Integration

A reliable manufacturer provides end-to-end solutions, combining design, engineering, and production support. This integrated approach ensures panels are not only technically optimized but also efficiently produced, thoroughly tested, and ready for deployment in demanding industrial and infrastructure applications.

Standards, Certifications, and Quality Assurance

Compliance with international standards and robust quality assurance are essential for any electrical panel manufacturing company to ensure safety, reliability, and long-term performance.

Key Certifications

- ISO 9001 – Quality management system ensuring consistent processes and product quality

- IEC 61439 – International standard for low-voltage switchgear and controlgear assemblies

- UL 508A – Certification for industrial control panels, widely recognized in North America

- CE Marking – Compliance with European health, safety, and environmental requirements

Quality Assurance Process

Manufacturers implement a structured QA workflow, including:

- Material Inspection – Verification of raw materials, busbars, and components for compliance and durability

- Assembly Monitoring – Standardized procedures to ensure precise wiring, accurate component placement, and structural integrity

- Testing – Dielectric strength, short-circuit withstand, insulation resistance, and functional performance checks

- Final Validation – Comprehensive inspection confirming that the panel meets design specifications and regulatory standards

Why Certification Matters?

Certified manufacturing companies differ significantly from small workshops. While workshops may assemble panels with basic functionality, certified companies provide:

- Proven design and engineering processes

- Use of high-quality, certified components

- Documented testing and traceability for each unit

- Assurance of compliance with international standards, critical for industrial, commercial, and export applications

Choosing a certified partner ensures not only safe and reliable electrical panels but also regulatory compliance and peace of mind for large-scale or technically demanding projects.

Custom Electrical Panel Solutions: From Design to Delivery

Different industries have distinct electrical requirements, from factories, solar power systems, HVAC installations, and utility networks to OEM equipment that must integrate precisely with specific machines. Unlike standard facility electrical systems, OEM equipment involves custom-built machinery, which requires electrical panels to be engineered and configured to match exact operational and technical specifications.

A professional electrical panel manufacturing company follows a structured workflow to ensure every solution meets client specifications:

- Requirement Analysis & Load Study: Assess power needs, control functions, and safety requirements.

- Electrical CAD Design: Develop precise schematics, panel layouts, and wiring diagrams.

- Component Selection: Choose certified components such as MCCBs, contactors, relays, and busbars to match performance and compliance standards.

- Fabrication & Wiring: Fabricate enclosures, assemble panels, and wire components with high precision, considering Design for Manufacturing (DFM) principles.

- Testing & Documentation: Conduct dielectric, insulation, short-circuit, and functional tests; provide detailed compliance and test reports.

- Installation & After-Sales Support: Guide on-site installation, offer maintenance advice, and provide support for operational reliability.

By delivering customized panels and leveraging DFM principles, manufacturers ensure optimized performance, seamless integration, and long-term durability for a wide range of industrial, commercial, and specialized equipment applications.

How to Choose the Right Electrical Panel Manufacturing Company

Selecting the right electrical panel manufacturing company is critical to ensure safety, reliability, and long-term operational efficiency. Consider the following evaluation criteria:

Proven Manufacturing Experience & Portfolio

- Review the company’s track record in delivering panels for diverse industries such as manufacturing, utilities, HVAC, renewable energy…

- Assess portfolio depth, project complexity, and capacity to handle both standard and customized solutions.

Certified Engineers and Production Processes

- Ensure the manufacturer employs qualified engineers and follows structured, documented production workflows.

- Look for adherence to international standards in design, assembly, and testing.

Compliance with International Standards

- Confirm certifications such as ISO 9001, IEC 61439, UL 508A, CE Marking, and other relevant safety or performance approvals.

- Verify that components used are certified and traceable to maintain system integrity.

After-Sales Service and Documentation Transparency

- Evaluate the manufacturer’s support for installation, maintenance, and troubleshooting.

- Ensure clear documentation is provided for testing results, component datasheets, and regulatory compliance.

Risks of Non-Certified Manufacturers

- Panels produced without proper certification or QA processes can lead to fire hazards, system downtime, failed inspections, or legal compliance issues.

- Choosing a certified, experienced partner mitigates operational risks and ensures safe, efficient, and reliable electrical panel performance.

THACO INDUSTRIES: A Reliable Electrical Panel Manufacturing Partner

THACO INDUSTRIES is a leading Vietnamese industrial corporation with strong OEM/ODM capabilities in electrical panel manufacturing, delivering customized, compliant solutions for industrial and commercial applications. With an integrated manufacturing ecosystem and engineering-driven approach, the corporation is positioned as a reliable long-term B2B partner for global markets.

Manufacturing Capabilities & Facilities

Electrical panels are produced at THACO INDUSTRIES’ Mechanical Complex in a dedicated manufacturing facility equipped with modern, highly automated production lines. The integrated fabrication system covers the full metalworking process, including slitting, laser cutting, stamping, panel bending, robotic welding, and comprehensive surface treatment from shot blasting to ED coating and powder coating. This ensures high dimensional accuracy, consistent quality, and durable, corrosion-resistant finishes suitable for demanding operating environments.

Process Standards & Manufacturing Compliance

All production and management activities strictly comply with international process and system standards, including:

- ISO 9001:2015 – Quality Management Systems

- ISO 14001:2015 – Environmental Management Systems

- ISO 45001:2018 – Occupational Health and Safety

- EN 1090 – Execution of Steel Structures

These standards ensure controlled manufacturing processes, traceability, and consistent output across large production volumes.

Product Standards & Regulatory Compliance

Each electrical panel undergoes rigorous inspection and functional testing to meet international product and regulatory requirements, including:

- IEC 61439 – Low-voltage switchgear and controlgear assemblies

- IEC 60529 (IP54) – Protection degree

- CE Marking, RoHS, and REACH compliance

This guarantees safety, electrical performance, and suitability for EU and global markets.

Product Portfolio

THACO INDUSTRIES manufactures a comprehensive range of electrical panels, including:

- Power Distribution Panels: SYN, MSB, ATS, MDB (floor-mounted), CP

- Control Panels: PLCP, SCADAP, PCP, FCP, LCP, ICP

All panels are fully integrated with enclosures, circuit breakers, contactors, switches, meters, and display units, delivered as complete, ready-to-install systems.

Customization for Global Clients

Panels are flexibly designed and expandable to meet specific project requirements and OEM equipment integration. Solutions are engineered to comply with EU, US, and Japanese specifications, ensuring compatibility with existing machinery, automation systems, and site conditions across offices, factories, construction sites, commercial buildings, and production lines.

Engineering & Integrated Services

Backed by an experienced engineering team and advanced design software, THACO INDUSTRIES manages the full OEM/ODM value chain – from order evaluation and design approval to 2D/3D drawings, material lists, fabrication, assembly, testing, packaging, shipment, on-site installation, and final commissioning. This integrated approach helps customers reduce costs, shorten lead times, and minimize reliance on multiple suppliers.

With a commitment to sustainable development, continuous production expansion, and long-term partnerships, THACO INDUSTRIES stands as a reliable partner for B2B clients seeking high-quality, compliant, and fully customized electrical panel solutions.

Contact THACO INDUSTRIES today for consultation or tailored electrical panel solutions: partsales@thaco.com.vn or +84 348 620 063.