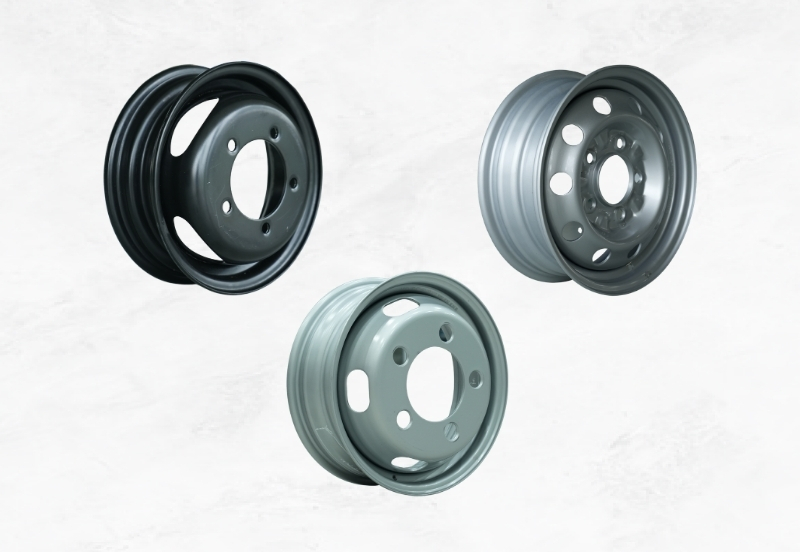

Custom Wheel Rims Manufacturer

An all-in-one manufacturing process integrates design, tooling, forming, coating, and inspection within a controlled production flow. This approach supports custom specifications, shortens lead times, while maintaining rigorous quality controls. Automated production lines and an experienced technical workforce sustain scalable production.

What THACO INDUSTRIES Manufactures

THACO INDUSTRIES handles the full production cycle - from design to finishing. The corporation’s wheel manufacturing capabilities include tubeless rims developed through integrated processes. This structure delivers scale, competitive price, and adherence to international standards.

Truck & Bus Wheel Rims (12" - 24.5")

Semi-trailers Wheel Rims (12" - 24.5")

Wheel Rims Production Technology

Billet Processing

Wheel manufacturing begins with the rim line and disc line. In the rim production stage, steel coils are roll-formed, flared, and hydraulically sized for roundness. The disc line uses high-tonnage press, progressive stamping, spinning, and machining to form hub profiles and bolt patterns.

Welding

In the welding line, finished rims and discs are precisely aligned and joined using robotic MIG/MAG systems under AWS standards. Automatic slag removal and dynamic balance testing help verify seam quality and stability before surface finishing and coating.

Surface Treatment & Painting

After welding, rims undergo shot-blasting before coating. ED systems apply an anti-corrosion base, followed by powder coating for uniform strength and color. Durability is validated through salt spray, adhesion, and accelerated weathering tests to ensure consistent protection. These measures reinforce the reliability of THACO INDUSTRIES’ wheel production for global OEM supply.

Packaging & Shipping

Finished wheel rims are stacked on iron pallets, layered with wooden boards and reinforced cardboard for protection. Automatic PE winding machines and plastic straps secure each load before container stuffing. This controlled process safeguards product integrity during transport and supports THACO INDUSTRIES’ reliable global logistics network.

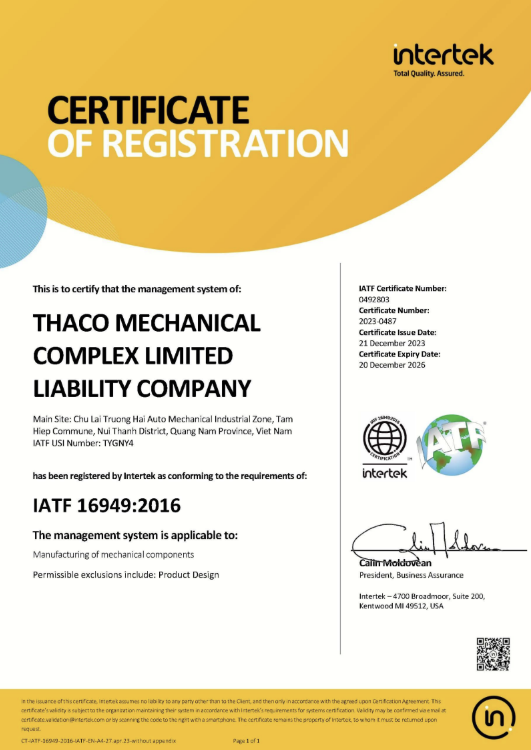

STANDARDS/CERTIFICATIONS

THACO INDUSTRIES holds DOT certification, complies with TRA standards (U.S. Tire & Rim Association), and meets SAE standards for global wheel manufacturing. Regarding the quality testing: air tightness test, Static balance test, Paint layer test, Bending fatigue test, Radial fatigue test, according to quality standards and certifications: TRA, FMVSS No.120, QC/T 241, QC/T 484, SAE J1204, SAE J267, DOT, OSHA, etc.

Our Markets

-

USA

-

Canada

-

Mexico

THACO INDUSTRIES

Customers

FAQs

What information do you need from me to quote a custom wheel?

What wheel sizes do you manufacture?

What is your typical lead time for production?

What is the minimum order quantity (MOQ)?

Are there any tooling or engineering setup costs?

Why partner with THACO INDUSTRIES on wheel rims manufacturing?

THACO INDUSTRIES provides capacity across specialized facilities for tractor rim manufacturing, truck wheel rim manufacturing, and export-ready production for commercial transport. Automated forming lines and robotic welding deliver consistent throughput, while coating systems protect against corrosion in demanding conditions. These capabilities ensure OEMs and distributors can depend on a stable supply for agriculture, logistics, and heavy-duty sectors.

Quality control runs through every stage, with welds, coatings, and fatigue life tested against international benchmarks. In addition, THACO INDUSTRIES’ R&D division advances industrial wheel manufacturing through new materials and design optimization. Projects extend to steel wheel manufacturing for cost-sensitive markets and innovations in tubeless rims, valued for reduced heat build-up and longer service intervals.