OVERVIEW

PASSENGER CAR INTERIORS COMPANY

Passenger car interiors manufacturing company was established in 2016, covering an area of 4,500 m², with a total investment of 40 million USD and an annual capacity of 300,000 product sets. This includes passenger car interior products such as head linings, floor carpets, trim assemblies - covering shelfs, board assemblies - luggage coverings, mudguards, and air-conditioners.

With advanced production technology and machinery imported from South Korea, the company manufactures and supplies high-quality products tailored to the specific needs of its customers. Notably, the company has delivered a range of products for the lines of two strategic partners, Kia and Hyundai.

With advanced production technology and machinery imported from South Korea, the company manufactures and supplies high-quality products tailored to the specific needs of its customers. Notably, the company has delivered a range of products for the lines of two strategic partners, Kia and Hyundai.

2016

Establishment year

40 million USD

Investment capital

300,000 products/year

Capacity

PRODUCTS

Passenger car air-conditioners

The company provides air-conditioners for Kia and Hyundai passenger cars. The products are assembled on state-of-the-art technology lines, ensuring adherence to inspection steps accordance with the standards of Hanon System - the leading air conditioning export group in South Korea.

Head linings and floor carpets

The company produces and supplies floor carpets and head linings for Kia and Hyundai passenger car models.

Trim assemblies - covering shelf and board assemblies - luggage coverings

The company produces and supplies trim assemblies - covering shelfs and board assemblies - luggage coverings for Kia and Hyundai passenger car models.

View all products

Mudguards

The company produces and provides high-quality and aesthetically pleasing mudguards for Kia's passenger car models.

PRODUCTION TECHNOLOGY

Head lining wet type production line

- Capacity: 100,000 products/year.

- Applying advanced wet technology, using different layers of materials, ensures that the product achieves high precision and aesthetic appeal.

- The production line is equipped with advanced machinery and equipment such as: a Headlining shape forming press, Headlining skin covering press, a skin covering pressing machine for headlining, foam pouring machines, and transverse cutting machines.

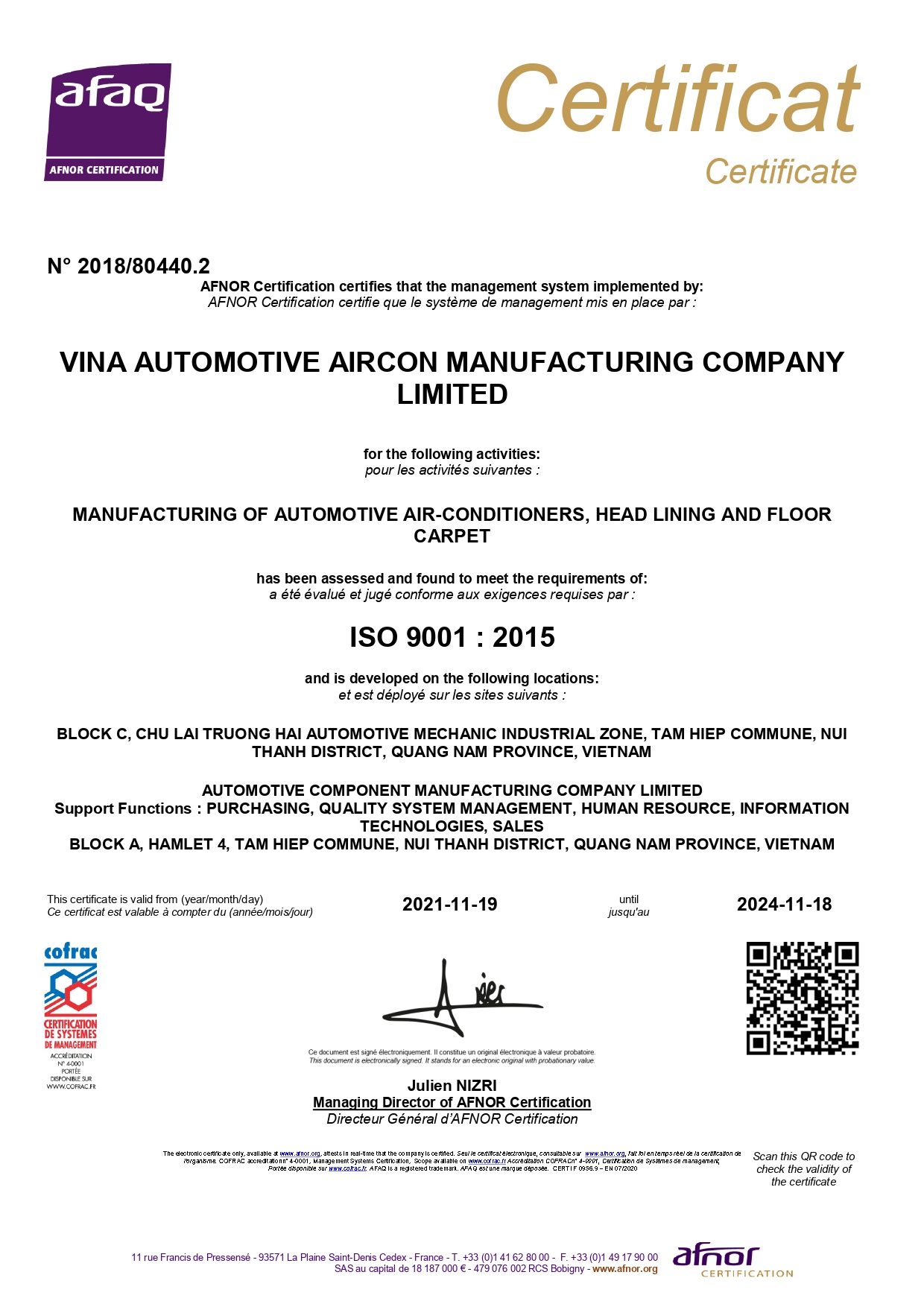

CERTIFICATES

The company has obtained certification for the Quality Management System IATF 16949:2016, ISO 9001:2015, and the Environmental Management System ISO 14001:2015. The products meet the stringent standards of customers.