Product information

Trusted Excavator-Parts Manufacturer for Global OEMs

For global OEMs and industrial operators, inconsistencies in quality or delayed shipments can disrupt entire projects. As a trusted excavator parts manufacturer, THACO INDUSTRIES delivers integrated, end-to-end solutions that optimize production, quality, and cost across the global supply chain.

With over 22 years of experience, we combine Vietnam’s industrial strength with international standards to support OEMs in construction, mining, logistics, and agriculture. THACO INDUSTRIES has created a comprehensive closed-loop value chain that encompasses: Business, Product Research & Development (R&D), Manufacturing, Delivery, and Maintenance. Each stage is closely monitored, enabling the Corporation to significantly reduce research and development time while facilitating quick and accurate improvements.

A Complete OEM Partner for Excavator Manufacturing

Integrated Design-to-Delivery Capabilities

THACO INDUSTRIES operates within a 320-hectare, USD 1 billion manufacturing center in Chu Lai, Vietnam – one of Southeast Asia’s most advanced industrial campuses with a fully integrated production chain.

This integration allows us to maintain full control over cost, quality, and delivery timelines. As a certified excavator attachment manufacturer and excavator spare parts manufacturer, we serve OEMs that require large-scale production with strict compliance to ISO 9001:2015, ISO 14001:2015, CE marking, RoHS, and REACH requirements.

What THACO INDUSTRIES Capabilities

1. Excavator Attachments

THACO INDUSTRIES designs and fabricates heavy-duty excavator attachments including buckets, couplers, and shovels engineered for endurance and precision. Using fiber-laser cutting, CNC presses, and automated welding, we ensure a perfect fit and superior wear resistance. These attachments are ideal for high-impact applications in mining, quarrying, and construction, where performance and service life are paramount.

2. Undercarriage Parts

Our undercarriage parts rollers, sprockets, and idlers are manufactured from high-strength steel and processed through precision machining and heat treatment. Each component is designed to withstand heavy loads, abrasive conditions, and long operational cycles. Rigorous testing ensures consistent hardness and mechanical integrity for demanding sites worldwide.

3. Excavator Spare Parts

As a certified excavator spare parts manufacturer, THACO INDUSTRIES supplies critical components such as hydraulic cylinders, pumps, and system housings. All are built under strict quality-management frameworks to meet international OEM specifications. Our replacement parts deliver lasting performance, enabling clients to reduce downtime and extend equipment lifespan.

4. Electrical Parts

In our dedicated electrical division, wire harnesses, control modules, and sensor assemblies are produced using automated cutting and crimping lines. Designed for precision and safety, these electrical systems optimize excavator performance while supporting broader industrial and automotive applications.

5. Engine Parts

As an advanced excavator parts manufacturer, THACO INDUSTRIES produces engine blocks, crankshafts, pistons, and housings using CNC machining, aluminum casting, and five-axis milling technology. Each part is inspected through CMMs (Coordinate Measuring Machines) and non-destructive testing to ensure compliance with global OEM standards.

6. Custom Excavator Components

With a team of experienced R&D experts and engineers, we collaborate with customers to co-develop custom excavator components using CAD/CAM, 3D prototyping, and simulation analysis. This capability allows clients to source tailor-made, ready-to-install parts that integrate seamlessly into global OEM projects.

Excavator Parts Manufacturing Process

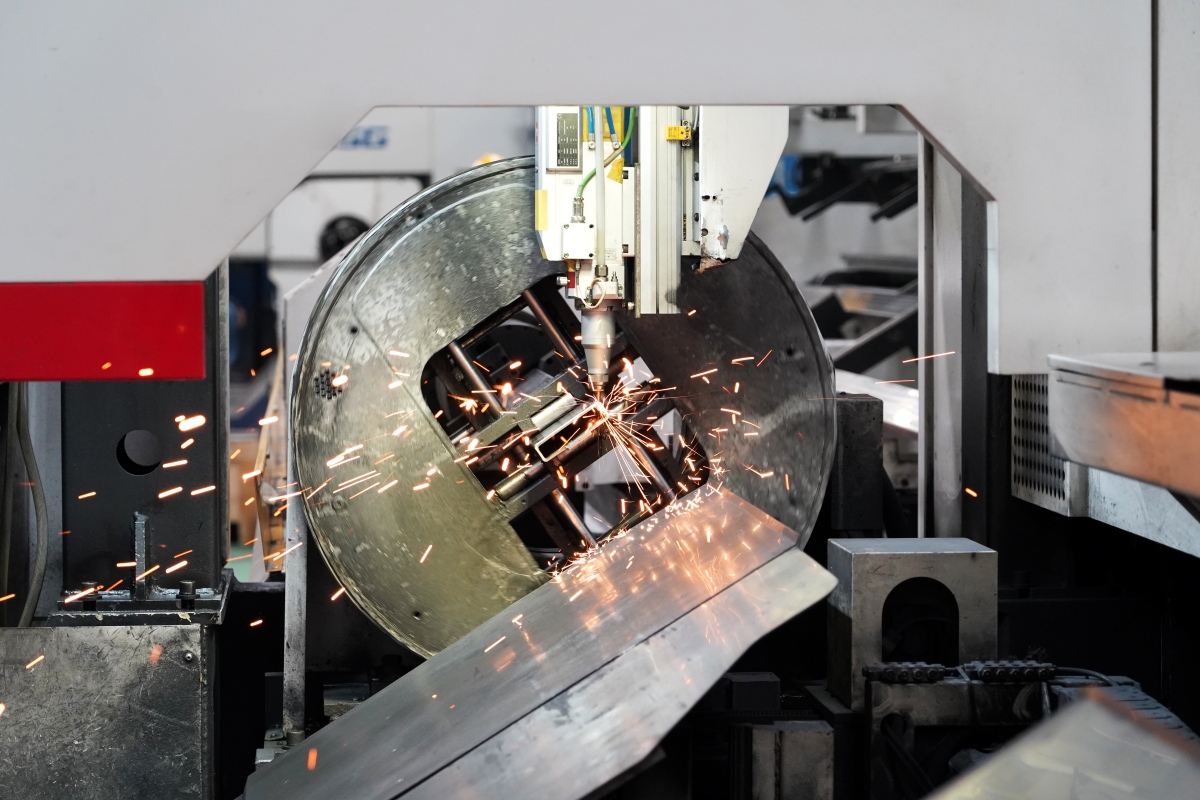

Material Preparation & Cutting

Every component begins with precise material preparation using slitting lines, CNC cutters, and advanced fiber-laser systems. These technologies ensure uniformity and tolerance accuracy from the very first process, setting a foundation for components that meet ASTM and OEM mechanical standards.

Machining & Shaping

Prepared blanks are transformed in CNC machining centers equipped with five-axis mills, hydraulic presses, and automated molding lines. Continuous program verification and dimensional checks ensure precision across complex geometries crucial for excavator undercarriages and engine components, where accuracy directly impacts performance.

Heat Treatment & Hardening

Wear-intensive components such as track links and sprockets undergo vacuum heat treatment and tempering. Metallographic analysis validates microstructure consistency, improving wear resistance and tensile strength. These processes guarantee the durability needed for heavy-duty excavation and mining operations.

Surface Treatment & Painting

Each component is shot-blasted, powder-coated, or ED-painted to protect against corrosion. Salt-spray and coating-thickness testing confirm surface quality. The result: clean, durable finishes that enhance handling, reduce corrosion, and extend product life in harsh environments.

Assembly

Coated parts go to specialized assembly lines where mechanical, hydraulic, and electrical systems are integrated into finished industrial equipment

Labeling & Serialization

All excavator parts are barcoded and serialized, allowing full digital traceability from casting to shipment. This ensures compliance, supports aftermarket maintenance, and simplifies part verification for global partners.

Inspection & Quality Testing

Our final inspection process includes dimensional verification, pressure testing, and vibration testing, using advanced CMMs. Operating under the ISO 9001:2015 system, THACO INDUSTRIES ensures every product meets international safety and performance benchmarks before delivery.

Packing & Delivery

Post-inspection, components are packed in moisture-resistant crates and reinforced export boxes. We use ERP-based logistics management to streamline customs clearance and shipping coordination. With optimized packaging and global logistics networks, we guarantee on-time delivery for every order.

Related Excavator Standards and Certifications

THACO INDUSTRIES’ manufacturing facilities are fully certified under:

- ISO 9001:2015 (Quality Management)

- ISO 14001:2015 (Environmental Management)

- EN 1090, ISO 3834

- CE, RoHS, and REACH (Export Compliance)

These certifications affirm our commitment to quality assurance, environmental responsibility, and international compliance, making THACO INDUSTRIES a preferred partner for OEMs and industrial manufacturers worldwide.

Global Excavator Parts OEM Partnership and Markets

As an OEM-grade manufacturer, THACO INDUSTRIES partners with clients across North America (USA, Canada, Mexico) and the European Union. Our integrated model helps global OEMs reduce supplier fragmentation, minimize logistics complexity, and enhance quality control.

Our long-term partnerships extend across construction, mining, logistics, and heavy equipment sectors with global industrial leaders. Through consistent quality and flexible manufacturing capacity, THACO INDUSTRIES continues to expand its footprint as a trusted Vietnam excavator supplier.

Why OEM/ODMs Choose THACO INDUSTRIES

1. Integrated Manufacturing Advantage

THACO INDUSTRIES operates a full “All-in-one” model within one campus covering Business – Product Research & Development (R&D) – Manufacturing – Delivery – Maintenance. This model reflects the core strength of THACO INDUSTRIES as a long-term OEM partner delivering reliable, consistent quality, shorter lead times, and optimized costs across the entire value chain.

2. Certified Quality Assurance

Quality management system (ISO 9001:2015), Environmental Management System (ISO 14001:2015), and CE Marking ensure repeatable quality and compliance with global OEM standards.

3. Advanced Technology Investment

THACO INDUSTRIES invests in modern technology and utilizes advanced machinery and equipment in the production of heavy-duty structures, such as the CNC cutting machine that is capable of cutting steel plates 10–80+ mm thick, forming thick sections on 800–3,000+ ton press brakes, and robotic welding systems applying MIG/MAG welding and submerged arc welding (SAW). To protect structural integrity, we apply post-weld stress-relieving heat treatment to stabilize critical weldments. When your project moves into precision assembly, our 3–5 axis CNC turning and milling produce pins, shafts, housings, and tight-tolerance interfaces, supported by deep-hole drilling/boring for long bushing bores, so your components fit, carry load, and perform reliably in the field.

4. Reliable Export and Supply Chain

A dedicated seaport located next to the campus further strengthens our logistics capability, allowing efficient handling of oversized and high-volume cargo while flexibly meeting diverse transportation needs for domestic and international customers.

FAQs

- Do you manufacture OEM excavator parts for US machines?

Yes. THACO INDUSTRIES supplies certified OEM excavator parts from Vietnam to North America, serving the US construction and mining sectors. - What excavator attachments do you produce?

Our range includes buckets, couplers, and rakes, fabricated through CNC fabrication and robotic welding for precision and durability. - Can you customize the engine or electrical components?

Yes. Our engineering teams co-develop custom engines and electrical systems such as wire harnesses, housings, and sensor assemblies using advanced prototyping tools. - How long does delivery from Vietnam to the US take?

Delivery time depends on order size and transport mode. Both sea and air freight options are available through our coordinated logistics network. - What certifications does THACO INDUSTRIES hold?

We comply with the Quality management system (ISO 9001:2015), Quality management system, Environmental Management System (ISO 14001:2015), and CE Marking, ensuring consistency and safety across all excavator components.

The Value of an Integrated OEM Partner

Managing multiple suppliers often leads to fragmented quality control and longer lead times. THACO INDUSTRIES simplifies this challenge through its comprehensive OEM ecosystem, combining design, manufacturing, assembly, surface treatment & painting, and export documentation in one certified system. The result is a faster, safer, and more cost-efficient supply chain.

Whether you require excavator attachments, spare parts, or custom-engineered components, our team ensures that every product meets international expectations for quality, safety, and sustainability.

Contact THACO INDUSTRIES

Partner with a global OEM manufacturer that delivers precision, quality, and reliability from Vietnam to the world.

Contact THACO INDUSTRIES to discuss your next excavator parts project:

partsales@thaco.com.vn