Product information

Trusted OEM Shopping Trolley Manufacturer for Europe

High-quality and durable shopping trolleys are essential for ensuring operational efficiency, safety, and long-term performance across various commercial environments. Selecting a capable shopping trolley manufacturer is critical to meeting load-bearing requirements, maintaining consistent product quality, and adhering to international compliance standards. THACO INDUSTRIES, with its integrated manufacturing ecosystem and engineering expertise, provides reliable, customizable, and globally compliant shopping trolley solutions for distributors and commercial partners worldwide.

Market Landscape for Shopping Trolleys

Although often perceived as simple tools, shopping trolleys are essential assets that directly influence store efficiency, customer flow, and operational performance. Designing and manufacturing trolleys for supermarkets, retail chains, and warehouse environments involves a highly industrialized process: from ergonomic design and material selection to precision forming, welding, and finishing. As retail demands increase, trolleys have become essential equipment for efficiency, safety, durability, ergonomics, and standards compliance.

The European market is driving strong demand for durable, ergonomic trolleys that can be customized to align with store branding. Retailers now prioritize high-load-capacity trolleys engineered to withstand frequent, intensive daily use, extend service life, and reduce maintenance costs to improve overall operational efficiency..

In a B2B context, the primary buyers include retail chains, supermarket groups, and logistics providers. Instead of consumer-grade products, they require industrial-grade, reliable solutions that can scale with expanding retail and logistics operations.. Their priorities are long-term supplier relationships, customization capabilities, consistent quality, and dependable supply stability.

To put the opportunity in perspective: the global shopping trolley market was estimated at approximately USD 4.2 billion in 2024, and is forecast to reach around USD 6.8 billion by 2033 – a compound annual growth rate (CAGR) of about 6.1%. This trajectory reflects rising investment in retail infrastructure, urbanization, and increasing emphasis on in‑store convenience.

Critical Factors in Choosing a Shopping Trolley Manufacturer

Selecting a reliable shopping trolley manufacturer is critical for retailers and logistics operators. The right partner ensures trolleys that deliver durability, ergonomic handling, safety compliance, and long-term operational efficiency. Several key elements determine the performance of shopping trolleys in high-demand retail environments. These include design flexibility, material strength, advanced manufacturing processes, and sustainability practices.

Design Flexibility & Customisation in Trolley Manufacturing

Retailers increasingly require customized trolleys that reflect their brand identity and operational needs. Key customization options include basket capacity (liters), handle ergonomics, wheel types, and nesting systems. Company logos and colors can also be incorporated, enabling seamless integration into store layouts.

Material & Structural Integrity

High-quality trolleys are typically made from galvanized or stainless steel wire, tubular frames, or hybrid steel-plastic structures. European standards generally require load capacities between 80 kg and 140 kg or 100 kg and 150 kg, which ensures durability and safety in heavy-use retail environments.

Manufacturing Technologies & Quality Standards for OEM Trolleys

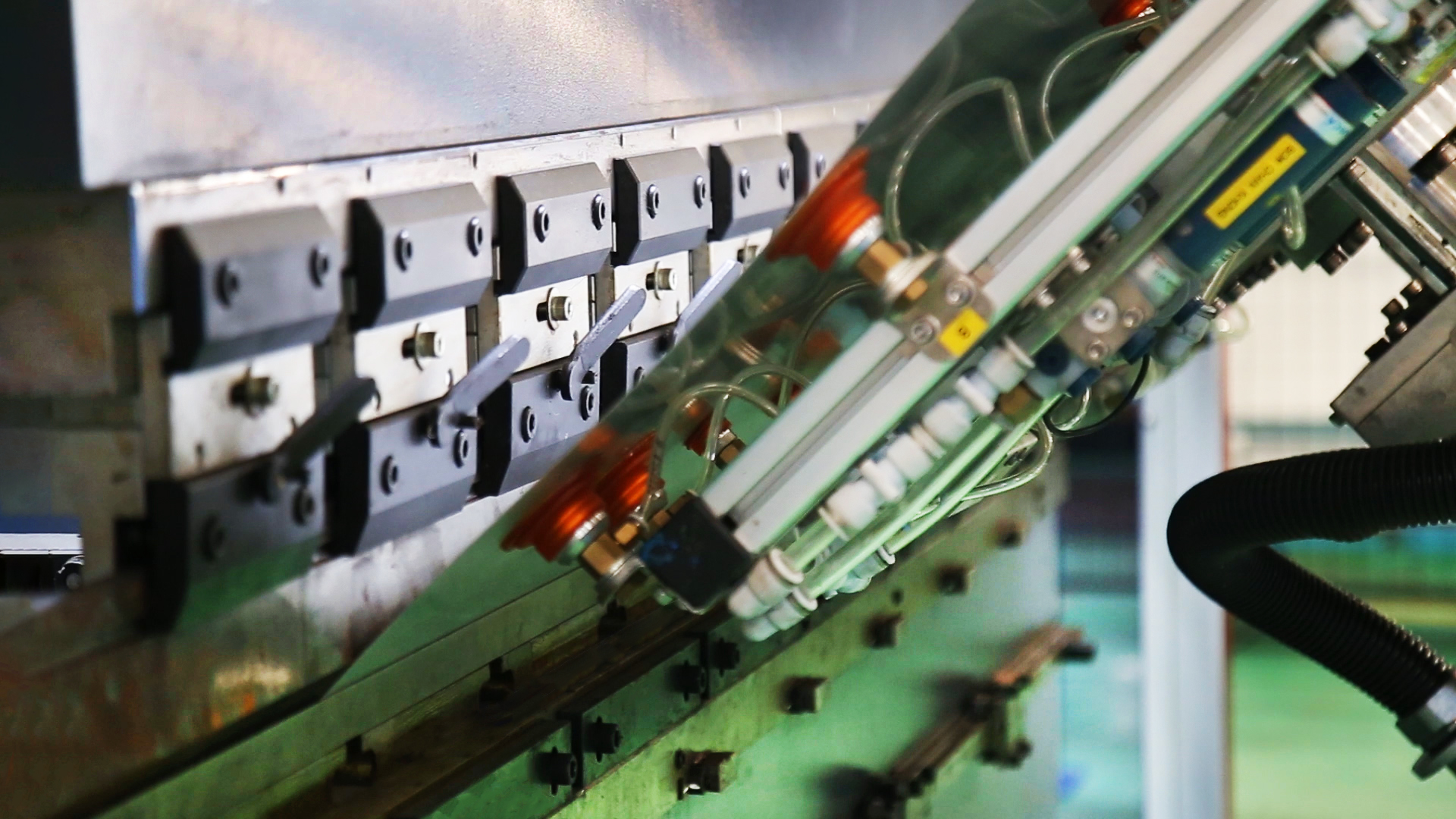

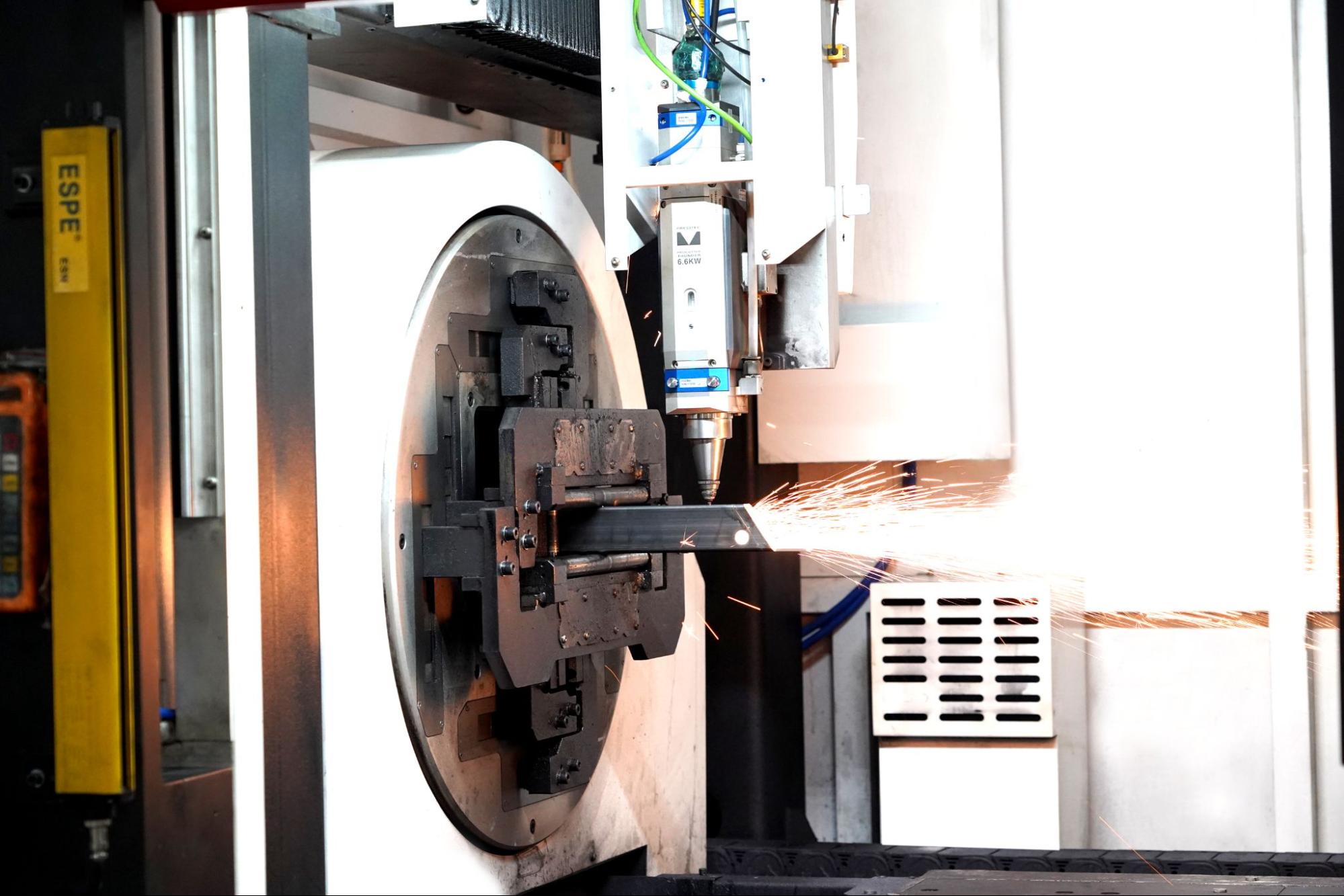

Modern trolley production relies on advanced technologies to ensure precision and consistency:

- Cutting & Forming: CNC, laser, and plasma systems for accurate shaping

- Joining & Assembly: Robotic welding and automated assembly lines

- Finishing: Powder coating and surface treatment for long-lasting performance

All processes operate under strict quality management and comply with ISO 9001:2015 and relevant EU standards for OEM trolleys.

Sustainability & Export-Ready Capability

European buyers increasingly prioritize environmentally responsible manufacturing. Key initiatives include:

- Closed-loop paint and wastewater treatment systems to minimize emissions

- Recycling of metal and plastic scrap within production cycles

- Compliance with ISO 14001:2015 (Environmental Management System) and ISO 45001:2018 (Occupational Health and Safety Management System)

These sustainability measures not only reduce environmental impact but also strengthen the export-readiness of trolleys. They meet ESG expectations from EU clients and support reliable supply chains for global partners.

Product Portfolio of Shopping Trolleys

Within retail, selecting a capable shopping trolley manufacturer is essential. It ensures access to solutions that deliver durability, operational efficiency, and safe material-handling performance. Leading shopping cart manufacturers offer a diverse range of trolleys that cater to different store formats, load capacities, and ergonomic requirements, combining practical design with long-term reliability.

Standard Retail Trolleys (60–240 L)

These trolleys are ideal for supermarkets and convenience stores, with basket volumes ranging from 60 L to 240 L. Key features include:

- Ergonomic handles and wheel design for smooth maneuverability.

- Nesting efficiency to save storage space.

- Load capacities of 120–140 kg, which meet typical European retail standards.

- Durable coatings and corrosion-resistant materials for long service life in high-traffic environments.

Large-Capacity & Heavy-Duty Trolleys

Designed for hypermarkets, wholesale stores, and warehouse operations, these trolleys support heavier loads, up to 275 L. Features include:

- Reinforced steel frames and joints for extended durability.

- Wide-base, high-traction wheels suitable for various flooring types.

- Optimized balance and structural integrity for safety during full-load transport.

- Suitable for indoor and outdoor use in warehouses or docks.

Hybrid & Plastic/Steel Mix Models

These combine lightweight plastic baskets with steel or tubular frames, offering:

- Reduced trolley weight without compromising load capacity.

- Quieter movement on different surfaces for a better customer experience.

- Enhanced corrosion resistance, making it ideal for humid or coastal regions.

- Easy maintenance and modular parts for long-term operational efficiency.

Custom OEM/ODM Trolleys

Tailor-made solutions allow retailers to meet unique branding and operational needs:

- Custom RAL colors, branded handles, coin locks, and self-locking wheels.

- Adjustable basket sizes, handle types, and accessory options.

- Ergonomic designs that align with store layout and customer workflow.

- Compliance with load capacity and safety standards in target export markets.

Comparison of Shopping Trolley Models

| Model | Capacity (L) | Frame Type | Application |

| Standard Wire Trolley | 100 – 150 | Metal (Zinc-coated steel) | Supermarkets, Retail chains |

| Hybrid Trolley | 80 – 120 | Metal frame + Plastic basket | Convenience stores, Hypermarkets |

| Full Plastic Trolley | 70 – 110 | Reinforced PP/HDPE | Airports, Duty-free shops |

| Compact Folding Trolley | 60 – 90 | Aluminum + Plastic | Small retail, Click & Collect zones |

Technical Specification & Quality Checklist

Before sourcing from any shopping trolley manufacturer, buyers often rely on a clear set of technical benchmarks to ensure product consistency, durability, and compliance – especially for EU-bound orders.

| Category | Inspection Criteria | THACO INDUSTRIES Capability |

| Material & Surface Finish | Galvanized steel, stainless steel, anti-corrosion powder coating | State-of-the-art coating line with advanced anti-rust protection |

| Size & Capacity | 60 L – 275 L; optimized height/width for aisle navigation | Custom dimensions designed to meet EU retail standards |

| Load Capacity | 80 – 140 kg (European standard) | Load testing, structural validation, and material fatigue inspection |

| Wheels & Accessories | PU/TPR wheels, coin locks, handle attachments | Dedicated assembly line for wheels and modular accessories |

| Export & Compliance | Container packaging, export documents (UK/DE/IT/ES) | Full logistics support with multilingual export documentation |

| Quality Certifications | Verification of certifications such as ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 | Holds ISO 9001:2015, ISO 14001:2015 & ISO 45001:2018, ensuring EU-ready product quality and compliance |

Typical Applications

Shopping trolleys now serve a wide range of operational environments, extending well beyond traditional retail applications. Depending on load capacity, maneuverability, and customization requirements, buyers across multiple sectors rely on solutions from experienced shopping trolley manufacturers. Common application groups include:

- Retail chains and supermarkets across the UK, Germany, Italy, and Spain, where standard and high-capacity trolleys support daily customer traffic and are continuous.

- Warehouses and fulfilment centers that require heavy-duty order-picking trolleys capable of handling heavier loads and frequent movement.

- Shopping malls and airports, which integrate branded or oversized trolley models to improve customer convenience in high-traffic environments.

- Industrial facilities that utilize trolleys as in-plant material-handling equipment for moving components, packaging materials, and lightweight tools—addressing niche OEM requirements.

- OEM private-label programs, where manufacturers produce customized, brand-specific trolley models engineered to meet the design, performance, and branding standards of major retail chains.

Why Choose THACO INDUSTRIES as Your Shopping Trolley Manufacturer?

Selecting the right shopping trolley manufacturer is critical for retailers, logistics operators, and private-label brands seeking durability, quality consistency, and operational performance. THACO INDUSTRIES stands out among global shopping trolley manufacturers thanks to its integrated production ecosystem, engineering expertise, and export-ready capabilities.

THACO INDUSTRIES is a trusted OEM/ODM partner in the household and commercial product sectors, delivering high-quality shopping trolleys backed by deep mechanical fabrication experience. The corporation operates a large-scale manufacturing complex equipped with machinery from the U.S., Germany, Italy, Japan, and South Korea, including CNC machining centers, automatic welding lines, powder-coating lines, and synchronized assembly systems.

Its comprehensive manufacturing model integrates every stage of production – processing, welding, surface treatment, painting, assembly, packaging, and delivery, ensuring end-to-end control, consistent quality, and full compliance with ISO 9001:2015 and ISO 14001:2015.

Each trolley is engineered using high-grade materials with a reinforced frame structure, optimized welds, and robust joint connections to enhance overall fatigue resistance. All welds meet AWS D1.1, D1.2, D1.6, and EN ISO 9606-1 standards, ensuring long-term structural stability. Surface finishing follows the SA 2.5 standard, while machining tolerances remain within ±0.5%. The electrostatic powder coating delivers high corrosion resistance while maintaining finish quality during prolonged use.. Industrial-grade wheels enable smooth, low-noise mobility and ensure excellent stability in high-traffic environments..

Before shipment, every product undergoes a multiple-stage quality inspection process, including mechanical load testing, surface finishing checks, corrosion resistance evaluation, and dimensional accuracy verification. Compliance with CE marking, REACH, and RoHS guarantees that all trolleys meet stringent EU safety and performance standards, making them fully suited for export to key European markets.

THACO INDUSTRIES maintains a certified, well-managed network of strategic suppliers, ensuring material consistency, full traceability, and scalable production capacity to support high-volume orders with short and predictable lead times. With a skilled engineering team and advanced simulation software, the corporation offers highly flexible design customization – covering RAL colors, handles, coin-lock options, wheels, and other brand-specific elements – while ensuring strict technical performance requirements are met.

By optimizing manufacturing costs relative to European producers and maintaining robust export-ready processes, THACO INDUSTRIES offers clients the benefit of competitive pricing without compromising quality. Flexible sales terms, optimized container-loading packaging, and full support for FOB, CIF, and FCA shipments help reduce logistics expenses and delivery timelines.

Committed to sustainable development and long-term partnerships, THACO INDUSTRIES continuously strengthens its production scale, product innovation, and international-standard manufacturing. With an integrated value chain and strong OEM/ODM capability, the corporation delivers durable, safe, and export-ready trolley solutions that meet the demanding requirements of global retail and logistics operators.

For project inquiries or technical consultation, contact THACO INDUSTRIES at partsales@thaco.com.vn or +84 348 620 063.