Product information

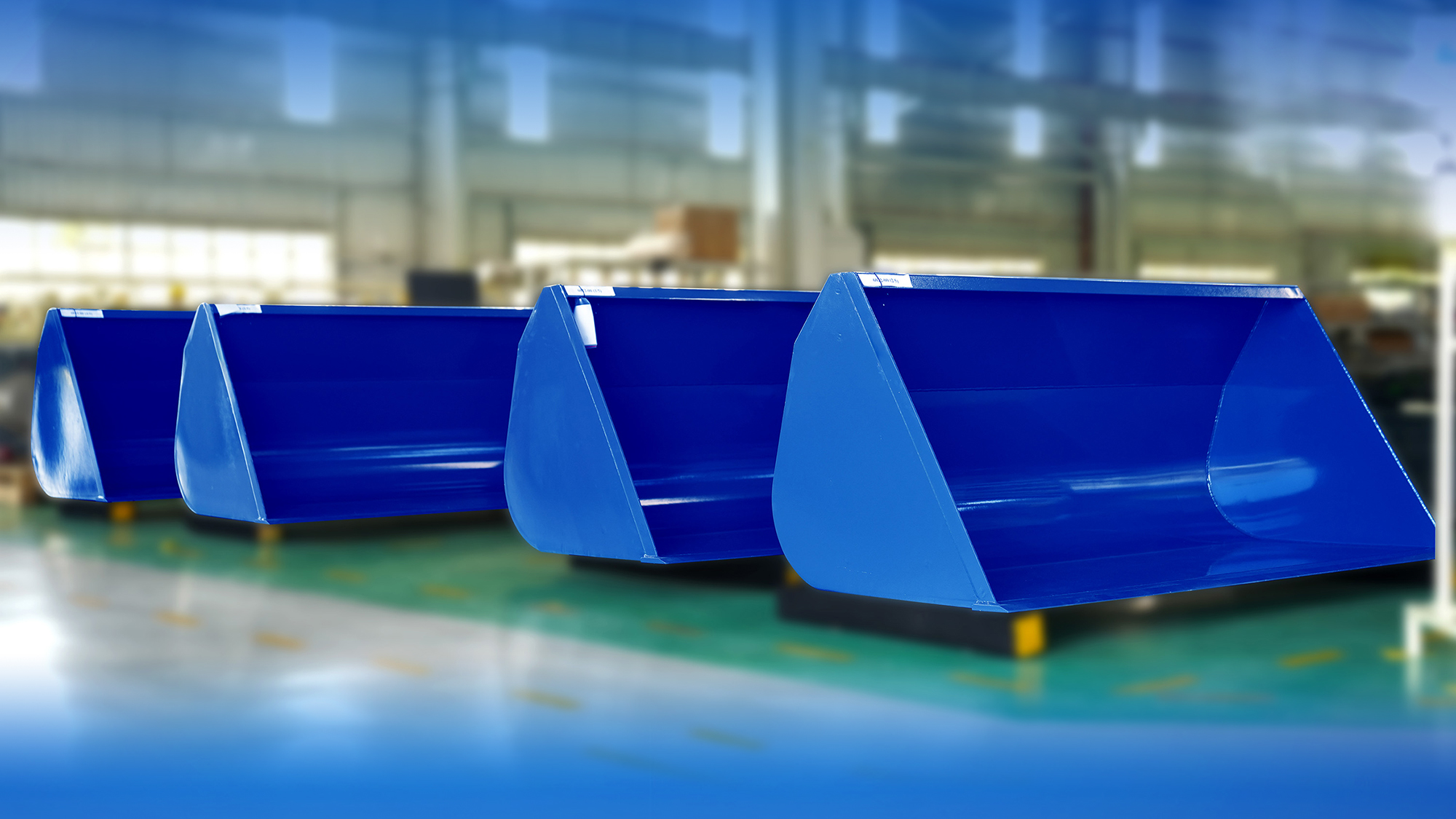

Mini Excavator Buckets Manufacturer And Custom Bucket Solutions

Leading OEM Excavator Bucket Manufacturer

As one of Vietnam’s leading Mechanical Centers, THACO INDUSTRIES delivers excavator bucket solutions that combine engineering precision, material strength, and consistent quality. Its advanced manufacturing capabilities support the production of mini, trenching, rock, and heavy-duty buckets for construction, mining, and infrastructure projects worldwide.

Stringent quality control processes and the use of high-strength, wear-resistant materials ensure consistent performance under demanding operating conditions.

THACO INDUSTRIES supports customers from design to delivery, providing comprehensive solutions in engineering, fabrication, welding, documentation, and international logistics.

Quick Facts:

- Export markets: Europe, Australia and other regions.

- Certified to ISO 9001:2015, ISO 14001:2015, ISO 3834, ATMS, and EN 1090-1.

Types of Excavator Buckets

THACO INDUSTRIES integrates research, design, fabrication, welding, surface treatment, and assembly within one location to maintain precision, reduce lead times, and ensure international compliance for every product.

THACO INDUSTRIES’ excavator bucket portfolio includes:

Mini Excavator Buckets

Engineered for landscaping, trenching, and confined-site operations, mini excavator buckets combine weight-optimized structure with high-strength steels such as S235, S355, 304 and 316 (stainless steel grades). Optional replaceable tooth systems and side cutters provide operational flexibility for different soil types and excavation conditions.

Trenching Buckets

Designed for utility and drainage projects, trenching buckets feature deep digging profiles and reinforced cutting edges to reduce abrasive wear. Precision-cut slots prevent soil buildup, while universal mount designs ensure compatibility with most mini and mid-size excavators.

Rock Buckets

Built for quarry and aggregate environments, rock buckets feature abrasion-resistant wear plates, heavy-duty tooth systems, and heel guards for superior penetration and durability. These attributes make them the preferred choice for high-impact, heavy-duty applications in demanding conditions.

Heavy-Duty Buckets

Optimized for mining, demolition, and construction, our heavy-duty buckets utilize wear-resistant steel with reinforced sidewalls and replaceable cutting edges. Ground Engaging Tools (GET), including teeth and edges, are heat-treated or quenched and tempered to achieve superior hardness and toughness, significantly extending service life.

Custom Excavator Attachments

THACO INDUSTRIES specializes in custom-engineered attachments (including buckets, rippers, couplers, and grapples) developed through advanced CAD (Computer-Aided Design) modelling and structural optimization. Each project is tailored to client specifications, with technical documentation and compliance support aligned to regional standards.

Excavator Solutions for Construction and Mining

Beyond attachments, we supply structural assemblies, lifting frames, shovels assemblies, tanks, and heavy-duty frames to major industrial operators. Our integrated design-to-manufacture capability ensures that every component achieves optimal performance across global mining and construction environments.

Excavator bucket manufacturing process

At THACO INDUSTRIES, every bucket represents the intersection of precision engineering, material science, and process control. We apply IATF 16949 derived core quality tools – PPAP (Production Part Approval Process), FMEA (Failure Mode and Effects Analysis), MSA (Measurement System Analysis), and SPC (Statistical Process Control), widely used in automotive and heavy equipment manufacturing to ensure consistent, globally aligned quality.

Material Preparation & Cutting

Production begins with verification of high-strength steel grades. Plates are slit, sheared, and laser-cut using CNC cutting machines and automated slitting lines. Operators confirm thickness and composition against design specifications, ensuring every blank aligns precisely with the CAD model.

Forming & Shaping

Cut blanks are processed through press brakes, stamping lines, and four-roller CNC plate rolling machines, where they are bent and shaped into precise contours. Coordinate Measuring Machines (CMM) and five-axis CNC milling guarantee dimensional accuracy, ensuring seamless fitment during assembly.

Heat Treatment & Hardening

Forged and welded components undergo controlled heat treatment in automated furnaces to increase hardness and impact toughness. Metallographic testing confirms that every bucket, whether mini or heavy-duty, meets specified wear-life criteria under demanding site conditions.

Surface Treatment & Coating

Surface integrity is ensured through shot blasting, powder coating, or electro-deposition. Coating thickness is digitally monitored, and samples are subjected to salt-spray tests to verify corrosion protection. The result: a durable, high-performance finish suitable for extreme climates.

Welding & Assembly

Using a combination of robotic and manual welding, our skilled team joins components under strict alignment jigs. Welds are visually and mechanically inspected, ensuring structural integrity before progressing to the next phase. Reinforcements, side cutters, and teeth are added for performance durability.

Labeling & Serialization

Each bucket receives a unique laser-etched ID and QR code for full traceability, linking it to material certificates, inspection records, and process documentation. This ensures rapid root-cause analysis and transparent quality control.

Inspection & Quality Testing

Before delivery, all buckets undergo dimensional, weld, and NDT (non-destructive testing) inspections. Environmental simulations and load trials validate structural performance. Compliance with ISO 9001:2015, ISO 3834, and EN 1090-1 guarantees that every attachment meets international standards.

Packing & Delivery

Products are sealed in protective wraps, palletized, and documented for global transport. Product shipments are organized under FOB, CIF, or DDP terms, ensuring safe and compliant global delivery.

Standards and Certifications

Every product from THACO INDUSTRIES complies with international standards, including ISO 9001:2015 (Quality Management System), ISO 14001:2015 (Environmental Management), ISO 45001:2018, ISO 3834, EN 1090-1 (Welding and Structural Integrity Standards), and ASTM.

These certifications validate our capability to meet the stringent quality, safety, and environmental requirements demanded by global OEM partners.

Excavator Bucket Product Range

Mini Excavator Buckets

Designed for precision excavation, these buckets handle light-duty excavation, grading, and material movement across soil types from clay to gravel. Three to nine teeth configurations ensure optimal penetration and manoeuvrability in restricted spaces.

Trenching Buckets

Built with narrow, reinforced profiles, these buckets produce clean, stable trenches ideal for pipeline, utility, and cable installations. Their optimized geometry reduces cutting resistance and preserves structural rigidity, ensuring long service life in demanding trenching operations.

Rock Buckets

For quarrying and mineral extraction, rock buckets incorporate abrasion-resistant wear plates and heavy-duty teeth engineered to endure severe impact and abrasive materials.

Custom Excavator Attachments

When standard solutions fall short, our engineering and R&D teams develop custom designs that match machine specifications, job-site environments, and regulatory requirements.

Global Markets and OEM Partnerships

THACO INDUSTRIES currently exports excavator buckets and attachments to Europe (Sweden) and Australia, while ensuring that its products are engineered to meet the technical standards of other key markets in North America, Europe, and the Asia Pacific region.

Our network includes OEM customers, industrial operators, and global manufacturers who rely on THACO INDUSTRIES for reliable quality, cost optimization, and supply chain efficiency.

As a strategic OEM supplier to leading global brands in heavy industries, automotive, construction and logistics, we have earned a reputation as a partner of choice for integrated mechanical manufacturing and engineering solutions.

Commitment to Quality and Durability

Every THACO INDUSTRIES product is engineered for precision, long-term durability, and full compliance with international manufacturing standards. Internal processes from steel sourcing and material certification to fabrication, finishing, and final inspection are governed by a comprehensive quality management system to ensure consistency across all production lines.

- Dimensional & fitment control: CMM/3D scanning of critical interfaces, pin size, ear width, and joint tolerances

- Mechanical & structural integrity: Hardness (HB/HRc), tensile, weld integrity (VT, MT, UT), impact (Charpy), and wear-resistance tests

- Coating & surface quality (where applicable): Paint adhesion test (ISO 2409) and coating thickness measurement

- Traceability: Each product is linked to material batch, process, and inspection records

By implementing continuous improvement systems, THACO INDUSTRIES ensures that each excavator bucket delivers long service life, reduced downtime, and optimized operational cost for our customers.

Frequently Asked Questions (FAQs)

- Do you manufacture OEM excavator buckets?

We specialize in the production of OEM excavator buckets in Vietnam. In addition, we can review and manufacture custom designs based on customer-provided drawings and technical specifications.

- Can you customize the excavator bucket for my equipment model?

Customization is available based on customer requirements and engineering drawings. For customers without existing designs, we provide engineering and manufacturing support based on equipment specifications and operating conditions.

- What is your delivery lead time to the US?

Lead times vary by product type and order quantity. For North American customers, we supply OEM-grade excavator attachments and provide sea or air shipments with full export documentation, ensuring reliable delivery and smooth customs clearance.

- How do you ensure quality and durability?

All production is conducted in accordance with ISO 9001:2015, ISO 14001:2015, and EN 1090-1, with welding adhering to ISO 3834. Each unit undergoes dimensional checks, NDT, and durability testing before delivery.

Why Choose THACO INDUSTRIES for Mini Excavator Buckets Manufacturing

THACO INDUSTRIES is an OEM manufacturer in mechanical engineering and supporting industries, with over 22 years of experience and operations based on a 320-hectare industrial campus backed by a total investment of USD 1 billion. Leveraging this manufacturing foundation, the corporation manufactures OEM components for excavators and construction machinery for global markets.

These components are manufactured within our centralized industrial campus, where R&D, fabrication, welding, surface treatment & painting, quality inspection, and export logistics are fully integrated into a unified production system. This proven manufacturing framework ensures consistent product quality, high process repeatability, and full compliance with international standards across diverse OEM programs.

Excavator components are produced in accordance with international standards, including ISO 9001:2015, ISO 14001:2015, EN 1090-1, CE requirements, and relevant ASTM standards for key export markets. Welding processes comply with ISO 3834, ensuring structural integrity and long-term durability in demanding construction, mining, and infrastructure applications.

Partnering with THACO INDUSTRIES for excavator components means gaining access to:

- Dedicated OEM manufacturing for standard and custom excavator buckets

- Engineering support covering design, material selection, and durability optimization

- Certified quality, welding, and structural compliance for global markets

Contact Us

Managing excavator bucket sourcing across borders can be complex. THACO INDUSTRIES simplifies the process with OEM design, fabrication, and shipping services backed by international certifications and global logistics.

Contact THACO INDUSTRIES to discuss your next manufacturing or OEM project: partsales@thaco.com.vn.