Product information

Key Insights Into Trailer Component Manufacturing

The global transportation and logistics industry is facing growing pressure to improve durability, safety, and cost efficiency in trailer systems. As demand rises for reliable, high-performance components, manufacturers are increasingly looking for partners that can deliver consistent quality at scale. In this article, THACO INDUSTRIES explores how professional trailer component manufacturing supports OEMs and fleet operators with dependable, application-ready solutions.

Overview of Trailer Component Manufacturing

Trailer component manufacturing directly determines load capacity, safety performance, and service life in modern transport and logistics operations. Behind every reliable trailer on the road is a network of precisely engineered parts that must work together under constant load, vibration, and changing road conditions. This process focuses on designing and producing the structural and functional elements that allow trailers to move safely, carry heavy cargo, and perform consistently over long service cycles.

Core components typically include the chassis frame, axles, suspension systems, hydraulic cylinder modules, braking systems, and landing gears. Each of these parts contributes directly to stability, load distribution, braking performance, and driver control. Their performance is not only a matter of engineering quality, but also of long-term operational safety.

Precision and manufacturing quality strongly influence how a trailer behaves in real-world conditions. Poorly manufactured components often lead to higher maintenance costs, early failures, and safety risks.

The trailer manufacturing industry itself is under increasing pressure to evolve. Rising freight volumes, tighter safety regulations, and demand for lighter, more durable trailers are reshaping how components are designed and produced. At the same time, OEMs and fleet operators are actively searching for reliable manufacturing partners that can provide stable quality, scalable production, and long-term technical support – not just parts, but confidence in how those parts will perform over time.

Key Considerations for Choosing a Manufacturer

Selecting the right manufacturing partner is not just a purchasing decision – it directly affects product reliability, delivery performance, and long-term operating costs. For OEMs and fleet operators, the following factors usually define whether a supplier can truly support growing business needs.

Production Capacity & Scalability

A capable manufacturer should be able to handle both stable mass production and sudden increases in order volume. Scalable production lines, standardized processes, and sufficient factory capacity enable high-volume orders to be fulfilled without compromising quality or delivery schedules.

Quality Assurance & International Compliance

A robust quality management system (QMS) is essential for consistent trailer component manufacturing. Reliable manufacturers operate under internationally recognized frameworks such as ISO, CE, and EN standards, ensuring traceability, consistency, and full regulatory compliance. This reduces risk for OEMs when supplying to highly regulated markets.

Advanced Machinery & Technology Capabilities

Modern equipment plays a major role in part accuracy and repeatability. Technologies such as robotic welding, automated coating systems, and precision-controlled machining help maintain tight tolerances, stronger weld integrity, and durable surface finishes. These capabilities are critical for safety-related trailer components.

Customization & Engineering Flexibility

Every trailer platform has unique requirements. A strong manufacturer must be able to adapt designs, materials, and production methods based on client specifications. This flexibility supports private-label production, OEM-specific standards, and evolving product designs without slowing down lead times.

Lead Time Reliability & Cost Efficiency

Consistent delivery schedules are as important as product quality. Optimized production planning, supplier network stability, and lean manufacturing practices allow manufacturers to offer competitive cost structures while maintaining dependable lead times – a crucial advantage in high-volume, time-sensitive supply chains.

Together, these considerations help OEMs identify partners who are not only capable of producing parts, but capable of supporting long-term growth and operational stability.

Modern Production Techniques

Modern trailer component manufacturing relies on a combination of advanced equipment, skilled engineering, and automated workflows to achieve high accuracy, consistent quality, and reliable output at scale. Each production stage is designed to minimize variation while maximizing efficiency and workplace safety.

Cutting & Shaping

High-precision laser cutting and plasma cutting are used to produce clean edges and complex geometries, while bending and shearing processes shape metal sheets and profiles to exact specifications. These technologies allow tight dimensional control and reduce material waste.

Welding Processes

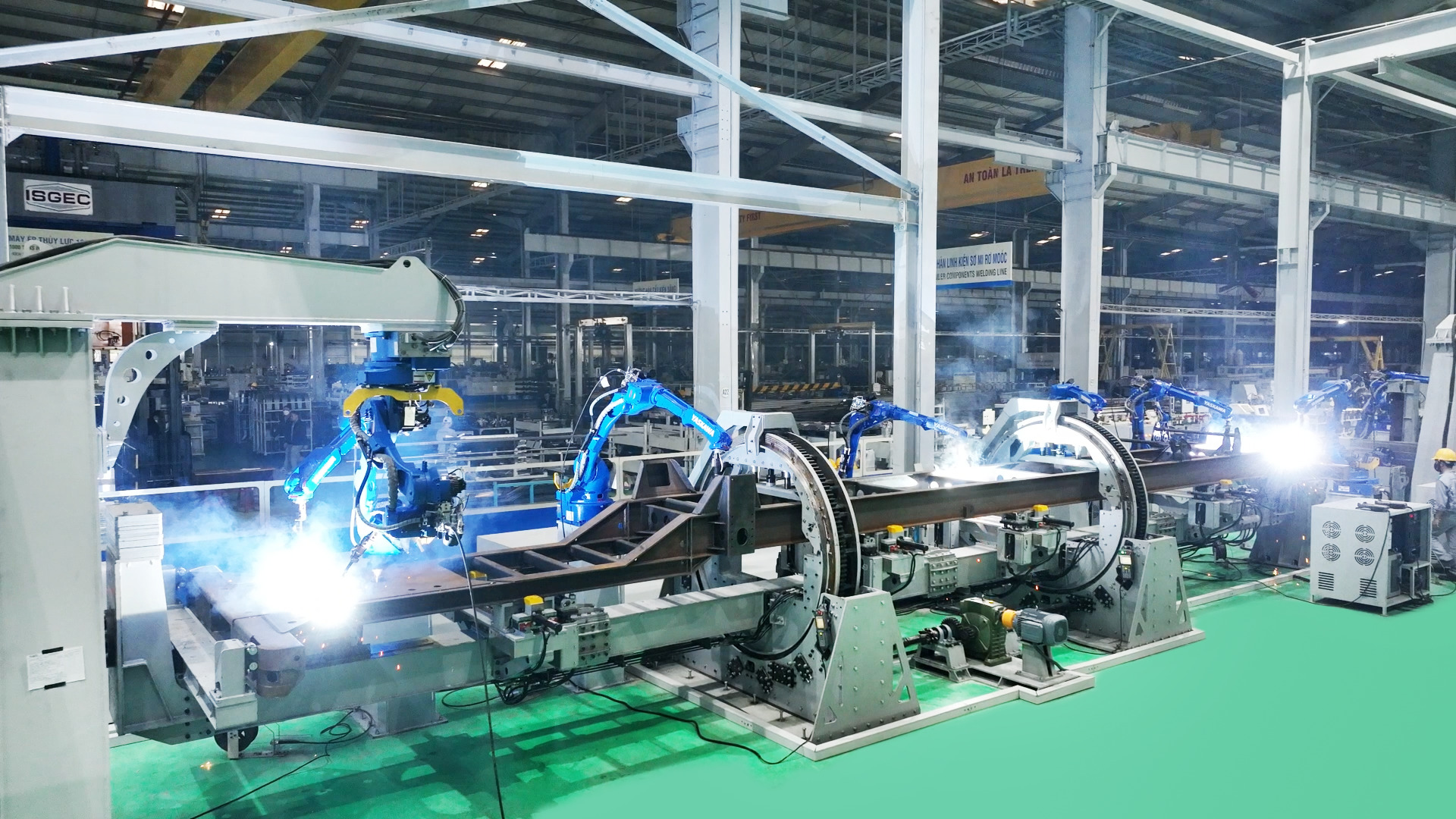

Structural joints are created using MIG and MAG welding, supported by robotic welding systems for repetitive, quality-critical operations. Large-scale welding stations are used for heavy chassis and load-bearing parts, ensuring consistent weld penetration and long-term structural integrity.

Assembly Operations

Assembly is handled on dedicated production lines designed for stable throughput and repeatability. These lines are optimized to support multi-industry requirements, enabling consistent fitting, secure fastening, and smooth integration of sub-assemblies. Process standardization at this stage helps reduce rework and improve overall production stability.

Surface Treatment & Corrosion Protection

Components are finished using shot blasting to clean and prepare surfaces, followed by powder coating and ED (electrodeposition) painting. Corrosion-resistant materials and protective coatings are applied to extend service life, particularly for trailers operating in harsh or coastal environments.

Quality Control & Precision Testing

Each production batch undergoes strict inspections, including dimensional verification, load testing, and surface quality checks. Automated measuring systems and manual audits work together to detect even minor deviations before products move to final delivery.

Impact of Automation

Automation plays a critical role across all stages. Robotic systems and synchronized production lines improve output consistency, reduce human error, and enhance workplace safety, while also allowing manufacturers to maintain high productivity without sacrificing quality.

THACO INDUSTRIES – Vietnam’s Leading Trailer Component Manufacturer

Recognized as a leading manufacturing base in Southeast Asia, THACO INDUSTRIES operates with an integrated, large-scale ecosystem designed to support high-precision trailer component manufacturing for global OEMs and industrial partners. The corporation combines engineering capability, automated production, and strict quality control within a fully synchronized manufacturing environment.

Integrated End-to-End Production Chain

THACO INDUSTRIES applies a vertically integrated workflow that connects every critical stage:

Design & Simulation → Fabrication → Welding → Painting → Assembly → Inspection → Packing.

This closed-loop structure allows tighter process control, faster problem resolution, and consistent product quality across both prototype and mass production.

Advanced Manufacturing Infrastructure

The production system is supported by modern facilities equipped with high-precision CNC machines, robotic welding systems, automated coating and surface-treatment lines, and standardized assembly lines. These technologies ensure repeatable accuracy, stable welding quality, and uniform surface finish even in large-volume manufacturing programs.

Proven Global Export Capability

THACO INDUSTRIES has built long-term export experience serving technically demanding markets, including the United States, Australia, Canada, Mexico, and key Asian countries. This international exposure enables the corporation to align its production, documentation, and quality systems with diverse regulatory and certification requirements.

Engineering & R&D Strength for Customized Solutions

A core advantage of THACO INDUSTRIES is its highly skilled R&D and engineering team, capable of developing customized designs and technical solutions based on specific customer requirements. Through advanced simulation software and in-house prototyping, the team supports product optimization, structural validation, and tailored performance – allowing partners to receive components precisely adapted to their applications and operating environments.

By combining engineering depth, scalable production, and export-ready quality systems, THACO INDUSTRIES delivers trailer components that meet both performance and reliability expectations for global transportation and logistics industries.

Choose THACO INDUSTRIES – Reliable Trailer Component Manufacturing Partner

THACO INDUSTRIES serves as a long-term manufacturing partner for OEMs and fleet-focused businesses that need stable quality, technical depth, and scalable capacity in trailer component manufacturing. With a strong foundation in mechanical fabrication and export-oriented production, the corporation supports both short development projects and large, continuous supply programs.

Customization for Real-World Applications

Components are developed based on client drawings, load conditions, operating environments, and regulatory requirements. This approach allows each part to match the actual performance demands of different trailer platforms.

Flexible Capacity for Any Production Scale

From pilot batches to full-scale manufacturing, production systems are structured to adapt quickly to volume changes while maintaining consistency in quality and dimensional accuracy.

Compliance with Global and Regional Standards

Manufacturing processes follow internationally recognized quality frameworks such as ISO and IATF, while also aligning with market-specific requirements:

- North America: DOT, AAR, ANSI, TOFC, FMVSS

- Australia & Europe: ADR, ECE, COC, EC, REACH, RoHS

This ensures every component is suitable for export and ready for use in demanding regulatory markets.

Engineering Support Beyond Production

Engineering teams actively support design optimization, technical problem-solving, and prototyping to help shorten development cycles and reduce project risks.

Cost Efficiency & Long-Term Cooperation

Optimized production planning and a stable supply network help reduce manufacturing costs and shorten lead times. At the same time, THACO INDUSTRIES focuses on building long-term cooperation, supporting customers as their programs expand.

For businesses seeking a dependable partner in trailer component manufacturing, THACO INDUSTRIES delivers consistent quality, scalable production, and practical engineering support.

Contact THACO INDUSTRIES to discuss your project requirements: partsales@thaco.com.vn or +84 348 620 063