Product information

Laser Cutting Services for Precision B2B Manufacturing

In modern precision manufacturing, laser cutting services play a critical role in delivering accurate, efficient, and scalable fabrication. Partnering with experienced providers ensures high-quality processing of carbon steel, stainless steel, aluminum, and composite materials with minimal waste and superior edge quality. In the following article, THACO INDUSTRIES highlights why professional laser cutting services are essential for B2B production and maintaining competitive performance in global markets.

What is laser cutting?

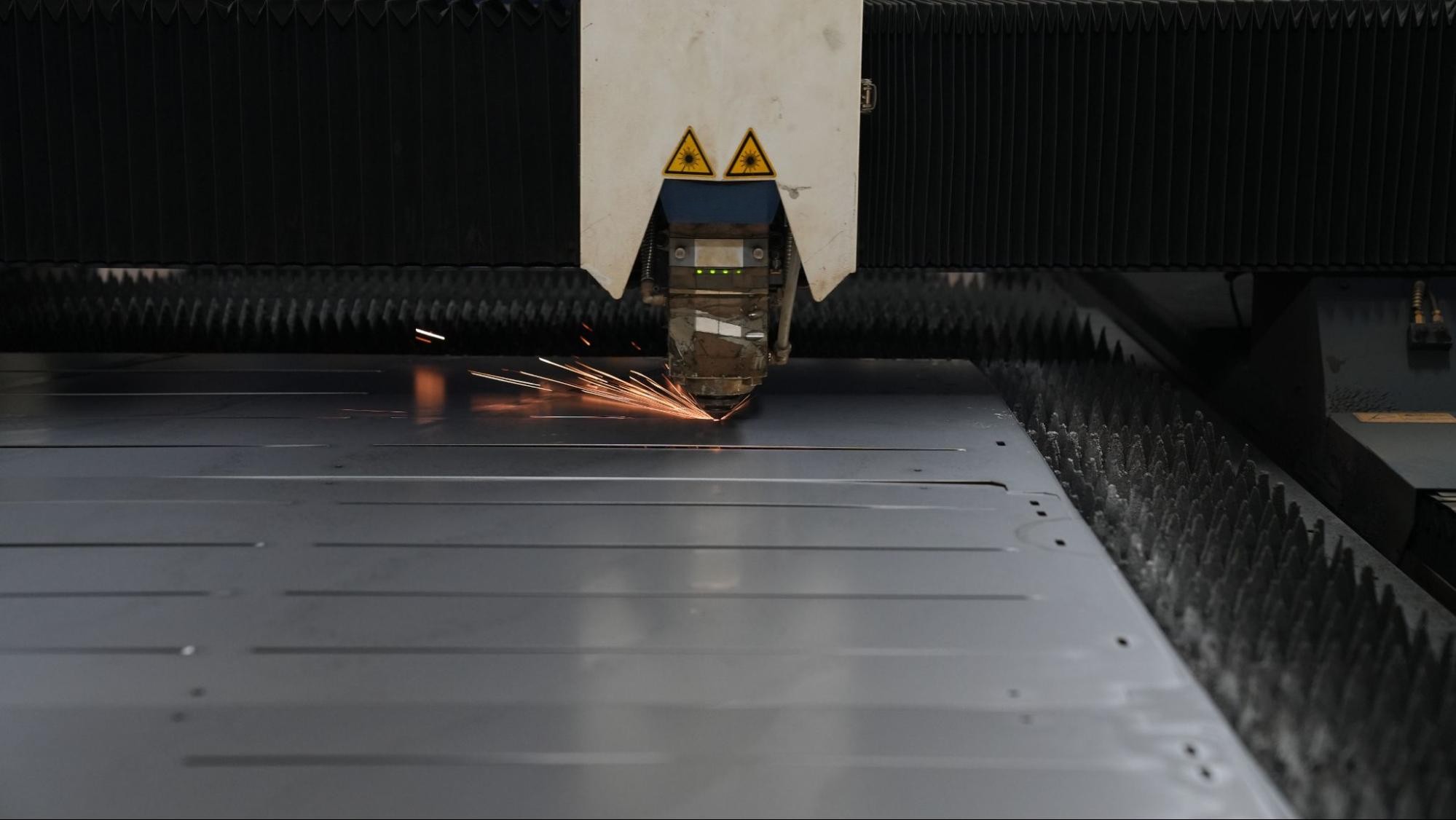

Laser cutting is a precision fabrication process that uses a high-powered, focused laser beam to cut, engrave, or etch materials with exceptional accuracy. The laser melts, burns, or vaporizes material along a programmed path, allowing for complex shapes and fine details that are difficult or impossible with traditional cutting methods.

Operational principles and laser types

Fiber laser systems generate beams through optical fiber doped with rare-earth elements, delivering wavelengths around 1.06 micrometers. This configuration excels at processing reflective metals, including aluminum, copper, brass, and various steel alloys. The technology achieves cutting speeds up to 50 meters per minute on thin-gauge materials while maintaining beam stability across extended production runs.

CO₂ laser systems produce 10.6-micrometer wavelengths through gas excitation, optimized for non-metallic substrates. These units process acrylics, polycarbonates, engineered woods, textiles, and composite laminates with minimal thermal distortion. The longer wavelength provides controlled absorption rates in organic materials, preventing charring or delamination during fabrication.

Industrial relevance for B2B operations

Modern manufacturing requires adaptable processes that accommodate rapid design iterations without retooling delays. Fiber laser cutting handles carbon steel sections up to 25 millimeters thick and stainless steel to 15 millimeters, maintaining positional accuracy within ±0.05 millimeters across cutting beds exceeding 6 meters in length. This capability eliminates secondary machining operations, reduces inventory complexity, and accelerates time-to-market for component assemblies in quality-critical applications.

View more: Contract Manufacturing Services: Expert Solutions for Global Enterprises

Key benefits of laser cutting for B2B clients

Industrial sheet metal processing through laser technology delivers measurable advantages in production economics, quality assurance, and operational flexibility.

Precision and accuracy

Laser cutting achieves exceptional precision through its ability to produce intricate shapes and maintain tight tolerances, making it indispensable for industries that demand superior accuracy and high-quality components. The process can cut materials up to 25 mm thick for carbon steel and 15 mm for stainless steel, ensuring both precision and productivity across diverse industrial applications.

In quality-sensitive sectors such as aerospace and medical equipment manufacturing, precision is vital to ensure every part strictly meets design specifications without deviation. This level of accuracy guarantees seamless assembly, optimal performance, and long-term reliability in critical operational environments.

Cost and material efficiency

Laser cutting significantly reduces overall production expenses by minimizing material waste and eliminating the need for expensive tooling. This process provides a cost-effective solution suitable for both bulk manufacturing and prototyping, helping businesses achieve greater operational efficiency.

For B2B clients, material efficiency plays a critical role in maintaining cost control while ensuring consistent product quality. Optimizing material usage not only lowers production costs but also supports sustainable manufacturing practices – an increasingly important factor in large-scale industrial operations.

Speed and scalability

Laser cutting offers exceptionally quick setup times for both prototype development and large-volume production runs, allowing manufacturers to respond swiftly to changing project requirements. This adaptability makes it ideal for businesses with diverse and evolving production needs.

Moreover, laser cutting systems can easily scale from small batches to full-scale mass production without compromising accuracy or efficiency. This flexibility ensures consistent quality and reliable throughput, meeting growing customer demands and supporting efficient production planning across various order sizes.

Flexibility

Laser cutting demonstrates exceptional adaptability, capable of processing a wide range of materials such as steel, aluminum, plastic, and composites. This versatility enables manufacturers to accommodate varied production demands across multiple industries without compromising precision or efficiency.

Flexibility is essential for creating customized solutions that meet unique design and technical requirements. By supporting intricate geometries, different thicknesses, and mixed-material assemblies, laser cutting becomes an ideal choice for industries seeking tailored production capabilities and greater design freedom.

Typical industrial applications

Laser cutting serves manufacturing sectors where dimensional accuracy, surface finish, and production repeatability determine product viability. The technology has become foundational across industries that depend on precision-engineered metal components.

Automotive and aerospace components

Body panel fabrication employs laser-cut brackets, reinforcements, and mounting plates. Chassis assemblies incorporate processed cross members, suspension mounts, and battery enclosures with welding preparation edges. Prototype development accelerates through rapid iteration without tooling investments.

Aerospace applications demand traceability and material certification compliance. Aluminum structural components for fuselage frames and wing ribs require burr-free edges and precise hole locations for rivet installation. Titanium alloy parts undergo laser processing with controlled edge quality to prevent crack initiation under cyclic loading.

Electronic enclosures and panels

In the electronics industry, laser cutting is widely applied to produce precise cut-outs, ventilation slots, and branding elements in electronic enclosures and panels. This process ensures smooth assembly, precise component fitting, and a clean aesthetic finish, which are critical for both functionality and product presentation. By maintaining tight tolerances and high edge quality, laser cutting supports the efficient integration of electrical components while enhancing overall product durability and design consistency.

Architectural elements and decorative products

Building facade panels incorporate laser-cut patterns for light transmission and environmental shading. Perforated metal screens with parametric hole distributions create dynamic effects while managing solar heat gain. Custom aperture sizes enable precise control of open area percentages and structural performance.

Interior architectural elements include partitions, ceiling panels, and decorative feature walls. Stainless steel, corten steel, and painted aluminum receive intricate geometric patterns or corporate branding. Furniture manufacturing employs laser-cut steel frames for commercial seating and shelving systems with precise tab-and-slot joinery.

View more: Steel Furniture Manufacturers: Key Insights for Businesses

Industrial machinery parts and tooling

Laser cutting is widely applied in producing gears, brackets, housings, and other functional components used in industrial machinery. This process ensures that each part achieves precise dimensions, clean edges, and superior consistency, all essential for maintaining high-performance standards. By delivering tight tolerances and repeatable accuracy, laser cutting enables the manufacture of tooling and machinery parts that meet rigorous operational and quality requirements in modern industrial production.

How to choose the right laser cutting service supplier?

Procurement decisions for laser cutting services require evaluation of technical capabilities, quality systems, and partnership reliability.

Proven expertise and industry experience

Established service providers demonstrate sector-specific knowledge through portfolio documentation and client references. Automotive tier suppliers require IATF 16949 quality management, while aerospace fabricators maintain AS9100 certification and understand material traceability requirements.

Technical expertise encompasses material science knowledge, processing parameter optimization, and design for manufacturability consultation. Experienced suppliers identify geometric features that challenge efficiency and propose alternatives that maintain functional intent while reducing cost. Long-term partnerships develop through consistent delivery performance and proactive problem resolution.

Advanced technology and certified quality standards

Equipment inventories should include current-generation fiber laser systems with power outputs appropriate to material thickness requirements. Processing capability verification includes maximum sheet dimensions, material thickness ranges, and cutting speed specifications.

Quality management certification demonstrates commitment to process control. ISO 9001 establishes baseline quality assurance practices, while industry-specific standards indicate specialized compliance capability. Environmental management certification (ISO 14001) and occupational safety compliance (ISO 45001) reflect operational maturity. CE marking indicates conformity with European safety directives.

Comprehensive and responsive support services

Full-service providers offer design review, prototyping, secondary operations, finishing, and logistics coordination. Engineering support includes DFM analysis to optimize part geometry. Post-processing capabilities such as deburring, bending, welding, and surface finishing eliminate the need for coordination with multiple subcontractors.

Communication infrastructure includes dedicated account management, web-based order tracking, and quality documentation portals. Response times for quotations and technical inquiries indicate operational efficiency. Flexible delivery terms under Incoterms 2020 (FOB, CIF, FCA) accommodate international trade requirements and customs coordination.

Why choose THACO INDUSTRIES for laser cutting services?

With 23 years of mechanical engineering expertise, THACO INDUSTRIES provides precision laser fabrication solutions for the automotive, mechanical, industrial, agricultural, civil, and commercial sectors.

Manufacturing capabilities and advanced machinery

The corporation operates 16 sheet laser cutting systems ranging from 3 kW to 30 kW capacity, sourced from Swiss and Korean manufacturers under European technology standards. The 15 kW fiber laser processes sheets up to 6.2 × 2.5 meters with a maximum thickness of 40 mm, while the 30 kW system handles 26 × 3.5 meter sheets up to 90 mm thickness at speeds reaching 50 meters per minute.

In addition, seven tube and profile laser cutting machines (2-20 kW) handle a wide range of structural sections, including round tubes (Ø20-730 mm), square tubes (50×50-520×520 mm), and shaped profiles with diagonal dimensions up to 730 mm. Maximum profile length reaches 13.3 meters with a thickness of 50 mm.

Software-integrated programming enables simultaneous multi-part production with automated nesting optimization. Touchscreen interfaces and automatic laser head positioning maintain optimal focal distance. Safety monitoring systems detect anomalies and prevent equipment damage.

The machines are equipped with integrated control software that enables simultaneous multi-part production with automated nesting optimization. Touchscreen interfaces and automatic laser head positioning maintain optimal focal distance, while safety monitoring systems detect anomalies to prevent equipment damage.

Quality, compliance with international standards, and after-sales support

Integrated quality management systems certified to ISO 9001, ISO 14001, and ISO 45001 govern production processes from material receipt through final inspection. Each component undergoes dimensional verification, surface quality assessment, and tolerance compliance checking.

In-process inspection includes first-article validation, statistical process monitoring, and CMM verification for critical features. Material certifications provide traceability for controlled alloys. The corporation’s infrastructure integrates laser cutting with stamping, CNC bending, welding, and surface finishing, delivering finished assemblies ready for installation.

Technical support extends beyond delivery to include prototyping assistance and design optimization consultation. In addition, THACO INDUSTRIES is fully prepared to scale up production capacity to fulfill large-volume orders within short lead times. Continuous technology investment reflects its commitment to long-term partnership development and adaptation to market demands.

Experience serving European and Asian, North American B2B clients

The corporation maintains established partnerships with OEM manufacturers across European and Asian markets, providing contract manufacturing under long-term supply agreements. Technical competence includes the interpretation of complex GD&T drawings and compliance with customer-specific specifications.

Export experience encompasses documentation preparation, quality certification, and logistics coordination. Incoterms delivery options (FOB, CIF, FCA) provide flexibility for customs clearance and freight optimization. Multilingual technical support facilitates communication with engineering teams across time zones.

Contact THACO INDUSTRIES via email: partsales@thaco.com.vn or hotline +84 348 620 063 for laser cutting services for custom solutions engineered to operational specifications and delivery requirements!