Product information

Custom Spring Manufacturers for Sale: What to Know

Sourcing precision-engineered springs from custom spring manufacturers for sale requires a strategic approach to component selection and supplier evaluation. Industrial applications demand springs that meet exact load specifications, dimensional tolerances, and material properties, requirements that standard stock components cannot fulfill. This THACO INDUSTRIES guide outlines the key technical criteria, production capabilities, and supplier qualifications that procurement and engineering teams should evaluate when selecting a custom spring partner.

Introduction to Custom Spring Manufacturing

Custom springs represent engineered components designed to precise specifications for load capacity, deflection rates, and operational environments. Unlike standard catalog springs, these components undergo tailored manufacturing processes to meet application-specific requirements in stress distribution, fatigue life, and geometric constraints.

Industries requiring customized designs face operational demands that generic components cannot address:

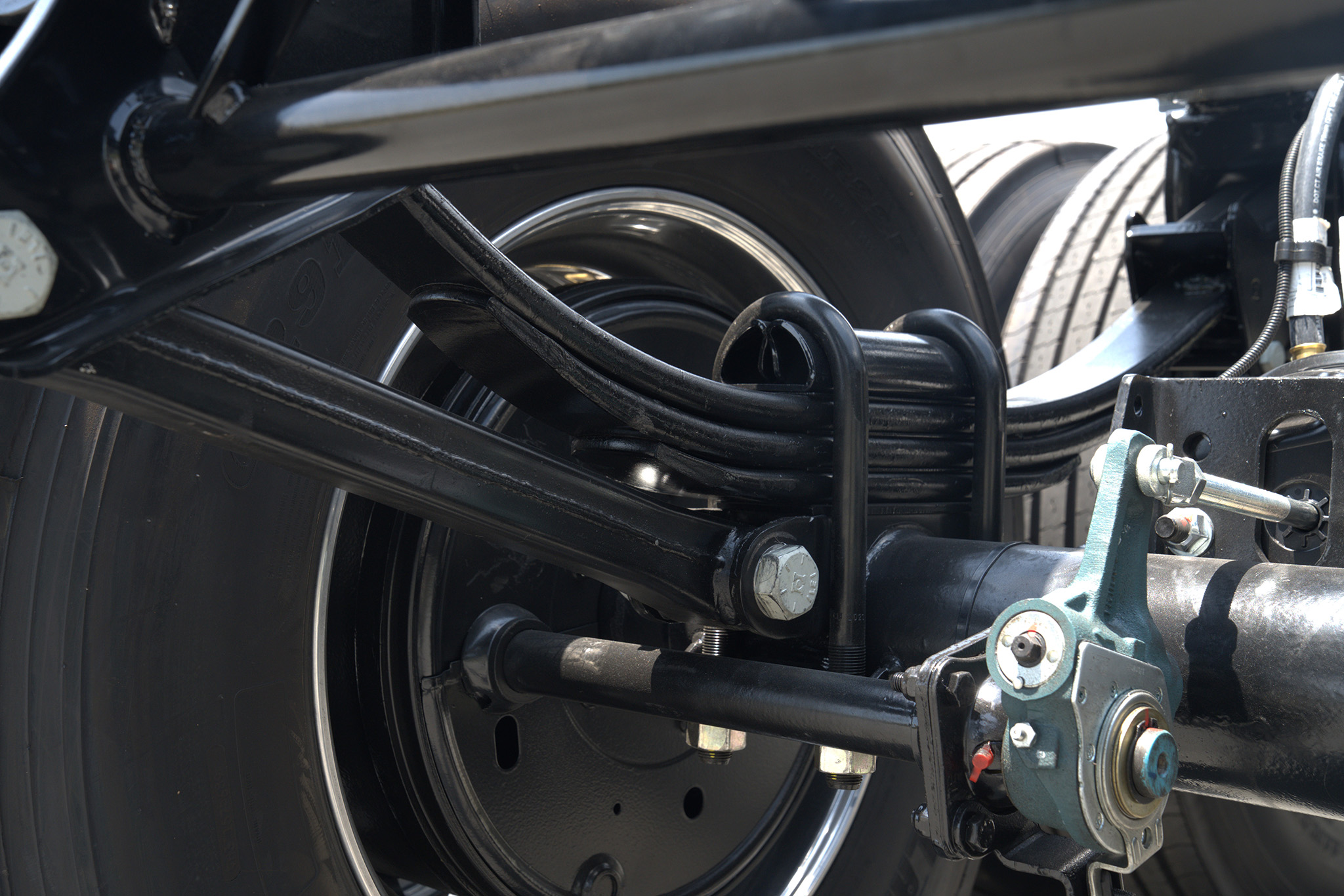

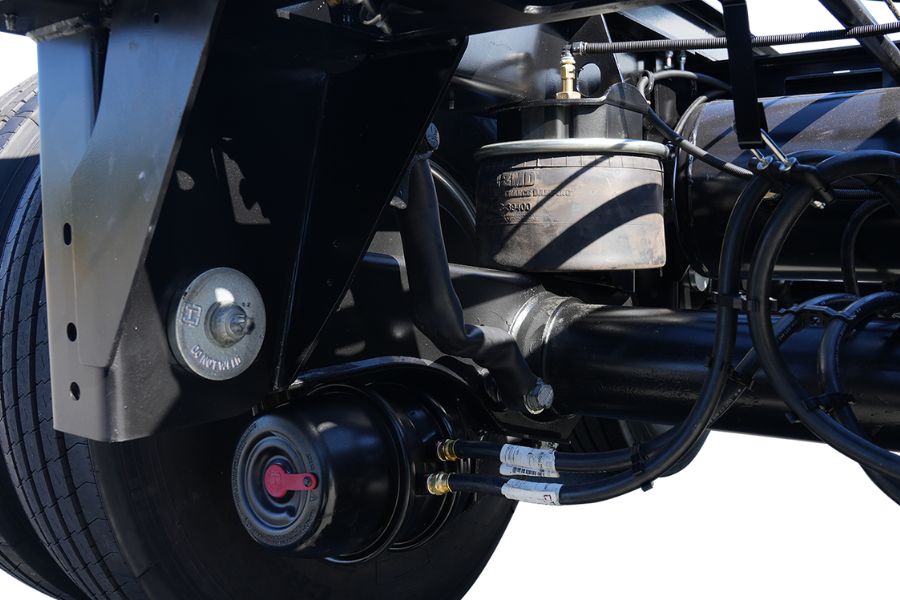

- Automotive suspension systems require springs engineered for specific vehicle weight distributions, road conditions, and handling characteristics

- Aerospace actuation mechanisms demand components meeting stringent weight limitations, temperature ranges, and fatigue life cycles.

The dimensional precision, material selection, and heat treatment processes directly impact component performance under cyclic loading conditions. Manufacturers employ advanced coiling techniques, finite element analysis, and metallurgical testing to ensure springs perform within specified parameters across temperature ranges and operational cycles.

The importance of selecting qualified custom spring manufacturers extends beyond initial component cost. Factors including material traceability, process certifications, and engineering support capabilities determine long-term supply chain reliability and product performance consistency.

Types of Springs Produced by Custom Manufacturers

Specialized custom spring manufacturers for sale produce diverse spring configurations to address mechanical requirements across industrial sectors, each requiring distinct engineering approaches and quality validation methods.

Coil Springs

Coil springs are helical-shaped mechanical components designed to absorb impact and store mechanical energy. They are widely used in vehicle suspension systems, industrial machinery, and precision devices. Depending on design specifications, coil springs can be compression, tension, or conical types — each offering specific mechanical responses. High-quality coil springs are typically manufactured from alloy or stainless steel to ensure consistent elasticity, fatigue resistance, and long service life under repetitive load conditions.

Leaf Springs

Leaf springs are one of the most robust and widely used suspension components in commercial vehicles, trailers, and heavy-duty machinery. They consist of multiple layers (or “leaves”) of high-strength steel stacked together, which distribute loads evenly and provide superior shock absorption. Thanks to their simple yet durable structure, leaf springs deliver excellent load-bearing performance, stability, and resistance to fatigue, making them ideal for demanding transport and industrial applications.

THACO INDUSTRIES specializes in leaf spring manufacturing, utilizing automated forming, precision heat treatment, and shot peening processes to enhance mechanical strength and fatigue durability. Surface protection methods such as powder coating and anti-corrosion finishing ensure long service life under harsh environmental conditions. Production strictly adheres to ISO 9001 and IATF 16949 quality management standards, guaranteeing product consistency for both OEM and aftermarket supply chains.

View more: Why Businesses Rely on ISO 9001 Certified Manufacturers

Torsion Springs

Torsion springs operate through torque when twisted, providing rotational force in mechanisms such as automotive hinges, lift gates, and industrial actuators. Manufacturers precisely control wire diameter, coil pitch, and leg configuration to achieve the desired torque and angular deflection.

Air springs

Air springs utilize compressed air enclosed within a flexible rubber bellow to provide cushioning and vibration isolation. They are commonly applied in heavy transport, rail systems, and industrial equipment, where they replace conventional steel springs to deliver adjustable stiffness and superior ride comfort.

Other types (Hydraulic springs, Progressive springs, Linear Springs)

Beyond traditional categories, specialized variants such as hydraulic springs, progressive springs, and linear springs serve unique engineering purposes. Hydraulic springs combine fluid damping with elasticity for precise motion control, while progressive springs offer variable stiffness to optimize performance under dynamic loads.

Materials and Processes in Custom Spring Fabrication

Material selection and processing methods determine spring performance characteristics, operational lifespan, and environmental resistance. The choice of base material establishes fundamental mechanical properties, while subsequent processing operations optimize performance for specific applications.

Common materials utilized in custom spring manufacturing include:

- Carbon steel alloys provide cost-effective solutions for general industrial applications with adequate strength and fatigue properties

- Stainless steel grades offer corrosion resistance in marine, chemical processing, or food production environments where rust prevention is critical

- Alloy steels deliver enhanced strength and fatigue characteristics for high-stress applications, including automotive suspension and heavy machinery

- Non-ferrous metals such as phosphor bronze and beryllium copper provide electrical conductivity and corrosion resistance, ideal for connectors, electronic assemblies, and non-magnetic applications

Heat treatment processes control material microstructure to achieve target mechanical properties. Stress relieving eliminates residual stresses from coiling operations, while tempering optimizes the balance between strength and ductility. Surface finishing methods protect against environmental degradation:

- Zinc plating provides corrosion protection for indoor applications and moderate exposure conditions

- Powder coating delivers enhanced durability and chemical resistance with customizable color options for identification

- Passivation improves the corrosion resistance of stainless steel components by removing free iron and promoting protective oxide layer formation.

Advanced manufacturing processes ensure consistent quality across production volumes. CNC coiling systems maintain precise control over wire feed rates, coil diameter, and pitch consistency. Automated inspection systems verify dimensional parameters and detect surface defects. Load testing equipment validates force-deflection characteristics against engineering specifications before component release.

Choosing the Right Custom Spring Manufacturer

Evaluating custom spring manufacturers for sale requires assessment of technical capabilities, quality systems, and operational flexibility to ensure long-term supply chain performance.

Quality Assurance and Certifications

ISO 9001 and IATF 16949 certifications demonstrate established quality management systems and process control capabilities. Material traceability documentation links finished components to raw material certifications, enabling failure analysis and quality audits. In-house testing laboratories equipped with load frames, metallurgical analysis equipment, and dimensional inspection systems verify conformance to specifications.

High-stress applications require non-destructive testing methods, including magnetic particle inspection or liquid penetrant examination, to detect surface defects. Fatigue testing validates component lifespan under cyclic loading conditions representative of operational environments.

View more: NDT Inspection Services: What They Are and Why They Matter

Production Capabilities and Scalability

Manufacturers must demonstrate the capacity to support both prototype quantities and high-volume production runs. Small batch capabilities enable design validation and testing before committing to tooling investments. Modern CNC coiling equipment and automated assembly systems deliver the efficiency required for cost-effective mass production while maintaining dimensional consistency.

Industry Applications and Experience

Established manufacturers serving automotive, aerospace, and industrial machinery sectors possess the engineering expertise and process validation required for demanding applications. Experience with suspension components, implantable device springs, or electronics contact springs demonstrates the capability to meet stringent performance and regulatory requirements.

Pricing, Lead Times, and After-Sales Support

Competitive pricing structures must reflect material costs, processing complexity, and quality assurance requirements without compromising component reliability. Clear communication regarding production schedules, packaging specifications, and shipping arrangements prevents supply chain disruptions. Technical support, including finite element analysis, material recommendations, and design optimization services, adds value beyond component supply.

Partner with THACO INDUSTRIES: Reliable Custom Spring Manufacturer

THACO INDUSTRIES operates as a trusted global partner delivering precision-engineered spring components through advanced production technology and rigorous quality control systems. The corporation manufactures diverse spring types, including multi-leaf springs for light trucks, medium-duty trucks, heavy-duty trucks, semi-trailers, and aftermarket leaf springs.

As Vietnam’s leading OEM manufacturer, THACO INDUSTRIES maintains certifications to ISO 9001:2015, IATF 16949:2016, and ISO 14001:2015 standards. The Automotive Springs Manufacturing Plant operates at 85% automation utilizing MES, SCADA, and ERP management systems to ensure process consistency and traceability. Produced on an advanced technology production line with an automated system of machinery and equipment, and utilizing materials along with a design and inspection process in accordance with Japanese standards (JIS G 4801; JIS B 2710; JASO C 601 & JASO C 604). Products demonstrate superior elasticity, durability, and load-bearing capacity across diverse operational environments, reflecting the precision and reliability achieved through these standardized production systems.

The corporation’s R&D capabilities include technical drawing design, 2D and 3D simulation, and comprehensive product analysis and calculation, enabling optimized manufacturing processes and customized product development. THACO INDUSTRIES supplies components to custom spring manufacturers for sale in domestic and international markets, including North America, Australia, Germany, Dominica, and South Korea.

Procurement professionals seeking precision spring components should submit technical drawings or RFQs to discuss custom requirements with THACO INDUSTRIES engineering specialists. For inquiries or quotation requests, please contact us via email: partsales@thaco.com.vn or hotline: +84 348 620 063.