Product information

Kitting and Assembly Services for Efficient Production

Optimized supply chain performance depends on structured kitting and assembly services that consolidate component logistics and minimize process variation. Through advanced pre-assembly, inspection, and packaging operations, THACO INDUSTRIES supports OEMs and Tier 1 manufacturers in achieving stable production flow, reduced lead times, and enhanced traceability within high-volume manufacturing environments.

Introduction to Kitting and Assembly Services

Kitting and assembly services encompass systematic processes through which manufacturers prepare, organize, and pre-assemble component sets based on specific technical requirements. THACO INDUSTRIES operates advanced facilities that execute these processes primarily for automotive sector applications, where precision and consistency determine production success.

Kitting involves collecting automotive components, including brackets, fasteners, suspension elements, and wiring assemblies, into ready-to-deploy packages that synchronize with production schedules. Each kit contains precisely the components required for specific assembly stages, eliminating redundant material handling and reducing line-side inventory complexity.

Assembly services extend beyond component organization to include pre-assembly of modules and sub-components such as seat frames, leaf springs, and mechanical subframes. These operations ensure dimensional accuracy, material compliance, and adherence to OEM technical specifications before components reach final assembly lines.

Professional kitting and assembly services directly impact operational metrics. Manufacturing operations experience reduced error rates, improved material flow velocity, and lower labor allocation requirements when components arrive pre-organized and pre-assembled according to production sequencing.

View more: Custom Spring Manufacturers for Sale: What to Know

Understanding Kitting Services

Kitting transforms discrete inventory items into coordinated component sets that match production requirements with precision timing. This systematic approach addresses fundamental challenges in modern manufacturing environments where component proliferation and SKU complexity create operational inefficiencies.

What Kitting Involves

Kitting operations consolidate multiple stock-keeping units into single-package assemblies designed for specific production tasks. Specialized logistics personnel select components based on bill-of-materials specifications, verify quantities through scanning systems, and package materials according to usage sequences. Electronics manufacturing, medical device production, automotive component assembly, and distribution operations employ kitting methodologies to standardize material presentation. Representative examples include precision toolkits with calibrated instruments, medical supply packages configured for specific procedures, and promotional merchandise bundles prepared for retail distribution.

Benefits of Kitting for Businesses

Adopting kitting and assembly services enables manufacturers to achieve measurable gains in efficiency, accuracy, and cost management. By organizing materials into predefined kits, operations become more predictable, while production flow remains continuous and resource-efficient.

Operational improvements observed across production systems:

- Fewer handling errors: Consolidated kits reduce mis-picks and minimize component mix-ups, improving process reliability and minimizing unplanned downtime.

- Faster assembly throughput: Pre-arranged material sets ensure that every component is ready at the point of use, cutting idle time and supporting steady assembly-line momentum.

- Stronger inventory control: Managing materials at the kit level simplifies tracking, enables single-SKU management, and enhances synchronization with enterprise resource planning systems.

- Lower operational labor costs: Dedicated kitting areas allow repetitive accuracy, streamlined workflows, and economies of scale, all contributing to leaner labor utilization across production cycles.

Assembly Services Explained

Assembly services provide partial or complete product construction outside primary manufacturing facilities, enabling production networks to distribute fabrication tasks across specialized operations. This approach leverages focused expertise, dedicated equipment, and optimized workflows for specific assembly sequences.

Types of Assembly Services

Sub-assembly operations produce intermediate components that integrate into larger assemblies during subsequent manufacturing stages. These partial builds, such as wiring harnesses with pre-installed connectors, machined components with press-fitted inserts, or structural frames with welded reinforcements, arrive at final assembly locations ready for immediate integration.

Final assembly services deliver fully constructed products that meet shipping specifications without additional processing requirements. Complete assembly operations encompass all fabrication, joining, testing, and packaging steps necessary to produce market-ready units.

Custom assembly solutions address unique manufacturing requirements through tailored processes designed for specific product architectures or production methodologies. Engineering collaboration establishes specialized workflows, fixturing arrangements, and quality verification protocols aligned with particular technical specifications.

Value of Outsourced Assembly

Professional assembly partnerships strengthen manufacturing performance through disciplined quality control, skilled labor, and advanced inspection capability. Consistent work standards and statistical process management sustain accuracy and reliability across every production run.

Outsourcing assembly operations streamlines internal resources by reducing labor intensity and facility overhead. Manufacturers gain the flexibility to focus on design, engineering, and core production activities while specialized partners manage complex assembly sequences.

Scalable capacity models provide rapid response to changing production volumes, supporting seasonal peaks, new product introductions, and project-based requirements without permanent infrastructure expansion. These collaboration models are widely adopted in industries such as consumer electronics, automotive systems, furniture manufacturing, and packaged goods, where precision assembly directly influences efficiency, consistency, and product quality.

Integration of Kitting and Assembly in Supply Chains

Combined kitting and assembly operations create efficiency gains throughout manufacturing supply chains. Pre-organized component sets feed directly into assembly workstations, eliminating staging delays and reducing work-in-process inventory.

Just-In-Time manufacturing achieves precise material synchronization:

- Component delivery schedules align with assembly line consumption rates

- Sequential kit preparation matches production take time

- Material availability is maintained without excess buffer stock

- Expedited replenishment cycles eliminated through systematic planning

Lean manufacturing principles reduce waste through streamlined operations:

- Redundant handling steps removed from material flow processes

- Storage requirements minimized through coordinated delivery sequences

- Lead times compressed between component receipt and product completion

- Non-value-added activities eliminated through process optimization

Production continuity improves with verified sub-assemblies:

- Pre-assembled modules replace field operations prone to interruptions

- Missing components and assembly errors are prevented through upstream quality control

- Installation time reduced with complete, tested sub-assemblies

- Schedule adherence maintained through reliable material delivery

Industrial Applications

Manufacturing sectors implement kitting and assembly services to address operational challenges specific to their production environments.

Electronics & Technology

Electronics manufacturing demands precise component organization and contamination-free assembly environments. Kitting services prepare circuit boards, cable assemblies, and device components in controlled packages that maintain electrostatic discharge protection and material traceability through production sequences. Pre-assembled modules, including populated circuit boards, connector assemblies with tested continuity, and housing sub-assemblies with installed hardware, accelerate final product construction while ensuring consistent solder quality, proper component orientation, and verified electrical performance.

Automotive Components

In the automotive sector, kitting and assembly play a critical role in achieving high precision, reliability, and compliance with strict safety standards. Each stage of the process contributes directly to performance stability and production efficiency in modern vehicle manufacturing.

THACO INDUSTRIES’ kitting and assembly solutions support the production of vehicle sub-assemblies, chassis parts, and suspension modules, helping OEMs maintain consistency in quality and optimize workflow in large-scale manufacturing environments. By ensuring seamless coordination between mechanical components and sub-systems, THACO INDUSTRIES enables its partners to achieve greater operational efficiency and product reliability.

Aerospace Applications

Aerospace manufacturing imposes stringent material certification, traceability documentation, and assembly verification requirements due to critical performance demands in flight applications. Kitting systems for aerospace components manage lightweight alloys, composite materials, and specialty fasteners that meet aerospace material specifications and maintain complete chain-of-custody documentation.

Assembly operations for aerospace structures require precision tooling, environmental controls, and non-destructive testing protocols that verify structural integrity and dimensional conformance. Pre-assembled aerospace components include bonded assemblies with certified adhesive cure documentation, riveted structures with verified fastener installation, and machined assemblies with dimensional inspection reports.

Healthcare & Medical Devices

Medical device manufacturing requires cleanrooms, biocompatible materials, and full traceability to ensure safety and compliance. Kitting operations assemble and package serialized, sterile surgical and diagnostic components. Assembly services build and test sub-assemblies in controlled environments with validation records. Medical kits include specified instruments and supplies organized for efficient clinical use.

Consumer Goods & E-commerce

Consumer product distribution uses kitting to create retail-ready bundles, promotional sets, and modular furniture packages that streamline handling and boost customer satisfaction. Common examples include pre-assembled furniture parts, multi-item gift sets, and seasonal collections. Assembly operations turn components into shippable products, such as furniture sub-assemblies, display fixtures, and promotional packs, ensuring fit, completeness, and quality, which reduces return rates.

How to Choose the Right Kitting and Assembly Service Provider

Selecting appropriate kitting and assembly partners requires a structured evaluation of capabilities, quality systems, and supply chain integration to ensure reliable performance and scalability.

- Scalability Assessment: Determines whether service providers have sufficient capacity, equipment flexibility, and workforce strength to handle current and future demand. Operations with seasonal or rapid volume changes benefit from partners maintaining reserve capacity and effective recruitment processes.

- Quality Assurance Evaluation: Reviews certification status, inspection methods, and process control systems to ensure consistent product quality. ISO 9001, IATF 16949, automotive QMS compliance, and industry-specific certifications demonstrate robust, regulated quality management.

- Logistics Integration Capabilities: Assesses how well providers’ warehouse management systems integrate with customers’ ERP platforms to enable real-time inventory visibility, automated replenishment, and seamless order workflows.

- Cost Structure & Contract Flexibility: Emphasizes transparent pricing models, measurable performance metrics, and adaptable service level agreements (SLAs) that support accurate budgeting and long-term collaboration.

THACO INDUSTRIES: Reliable Partner for Kitting and Assembly

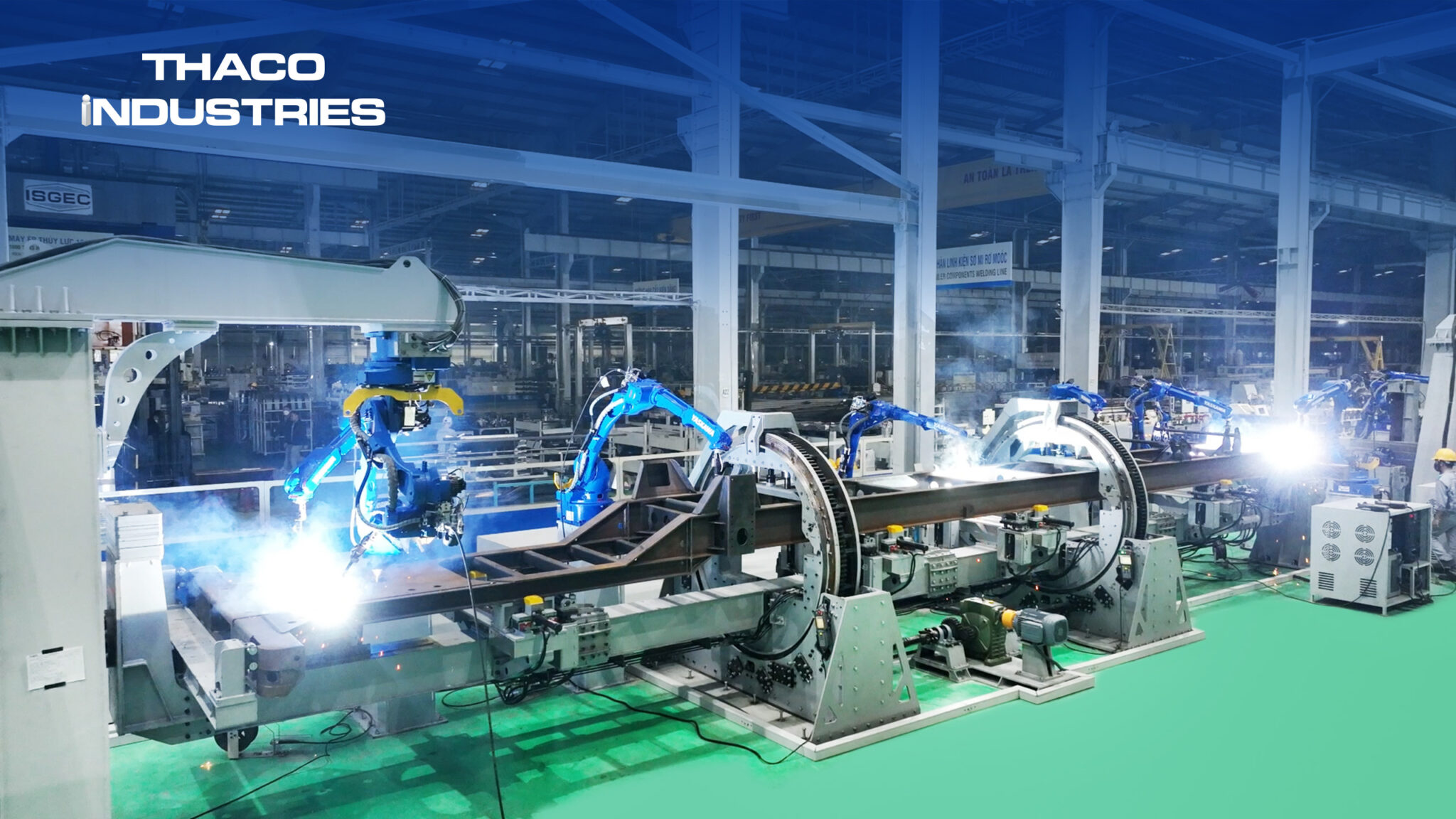

THACO INDUSTRIES serves as a leading OEM partner in Vietnam, providing end-to-end kitting and assembly services across automotive, industrial equipment, agricultural machinery, residential, and commercial sectors. Its operations integrate modern, automated manufacturing systems with intelligent management platforms for real-time monitoring and quality verification.

- Advanced Manufacturing Systems: THACO INDUSTRIES operates an advanced manufacturing complex covering 320 hectares, with a total investment of USD 1 billion. The corporation is equipped with state-of-the-art production lines featuring a high level of automation sourced from Germany, Switzerland, Japan, and South Korea. Its large-scale production capacity, supported by digital management systems, ensures consistent quality, real-time performance tracking, and full process transparency, meeting the stringent requirements of global partners in the mechanical and supporting industries.

- Quality & Inspection Control: THACO INDUSTRIES maintains rigorous quality assurance systems aligned with ISO 9001 and IATF 16949 standards, ensuring full compliance with international automotive and industrial requirements. The corporation enforces strict inspection protocols at every production stage, from material receipt to final assembly shipment to guarantee dimensional accuracy, material integrity, and complete traceability. Through robust process controls, skilled personnel, and validated procedures, THACO INDUSTRIES consistently meets customer technical specifications while upholding the highest levels of reliability and product quality.

- Lean Production Methodologies: THACO INDUSTRIES implements Lean and Just-In-Time principles, minimizes waste, optimizes material flow, and maintains on-time delivery across all operations.

- Engineering & Customization Support: With a dedicated team of engineers and technical experts, THACO INDUSTRIES provides customized knitting and assembly solutions tailored to specific customer requirements, optimizing production processes, lead times, and overall cost efficiency.

- Scalable Production Capacity: Flexible equipment investment and capacity expansion allow for high-volume production with short lead times aligned to customer demand patterns.

- Integrated Service Delivery: THACO INDUSTRIES provides delivery options under Incoterms, including CIF, FCA, and FOB, ensuring seamless logistics integration, reduced supplier complexity, and optimized total acquisition costs for customers.

With proven expertise in kitting and assembly services, THACO INDUSTRIES delivers reliable, high-quality, and scalable manufacturing solutions that meet global standards and diverse customer requirements, making it a trusted OEM partner for businesses across industries.

For collaboration opportunities or detailed consultation, please contact THACO INDUSTRIES via email at partsales@thaco.com.vn or reach our hotline at +84 348 620 063