Product information

What is Mechanical Processing? A Detailed Guide to Mechanical Manufacturing

Mechanical processing is one of the most essential stages in the field of mechanical engineering. This process focuses on creating components, machinery, and equipment based on the specifications of technical drawings. So, what exactly is mechanical processing, and what are the most common methods used today? Let’s take a closer look below.

What is mechanical manufacturing?

Mechanical processing is the use of machines, technology, and mechanical principles to manufacture high-precision mechanical parts and components that meet technical requirements. Specifically, engineers work with blanks or workpieces (produced by casting, forging, stamping, rolling, welding, cutting, etc.) and machine them on equipment such as lathes, milling machines, shapers, drills, grinders, presses, and laser cutters to produce finished parts.

Classification of mechanical processing technology

Mechanical processing technologies can be classified in various ways, with the two most common being:

By chip formation

Chips are excess material removed from the workpiece during machining.

Chipless machining technology

Chipless machining uses pressure or heat to change deform the workpiece producing chips. Methods include casting, forging, pressing, hot stamping, welding, and drawing. Punching and pressure forming are also typical examples.

This technology is usually applied to products that do not require very high precision. The resulting parts often have rough dimensions and must undergo additional finishing before use.

Chip machining technology

Chip machining, also called cutting machining, removes excess material until the part achieves the required shape, size, and surface quality. This process always produces chips as a byproduct.

Common operations include cutting, turning, milling, grinding, and planing. This method is typically used for parts that demand high precision and surface finish.

By Accuracy

Rough machining

Rough machining removes large amounts of excess material to shape the part. It involves processes such as cutting, broaching, or milling. Precision and surface finish are not the primary focus.

Engineers typically use slower spindle speeds and deeper cuts. CNC milling machines are widely applied for rough machining today due to their efficiency and accuracy.

Finishing

Finishing removes smaller amounts of material left after roughing, using methods like grinding, milling, turning, or honing. This step ensures a high-quality surface finish and dimensional accuracy.

Finishing requires higher spindle speeds and shallower cuts to meet strict standards for size, smoothness, and tolerance.

Superfinishing machining

Superfine or ultra-finishing creates extremely precise parts with super-smooth surfaces and minimal tolerances, often using advanced equipment and tools such as single-crystal diamond (SCD) cutters.

This process is commonly applied in specialized industries such as scientific instruments, high-end machinery, optical engineering, medical devices, and aerospace.

Popular mechanical processing methods today

Traditional mechanical processing

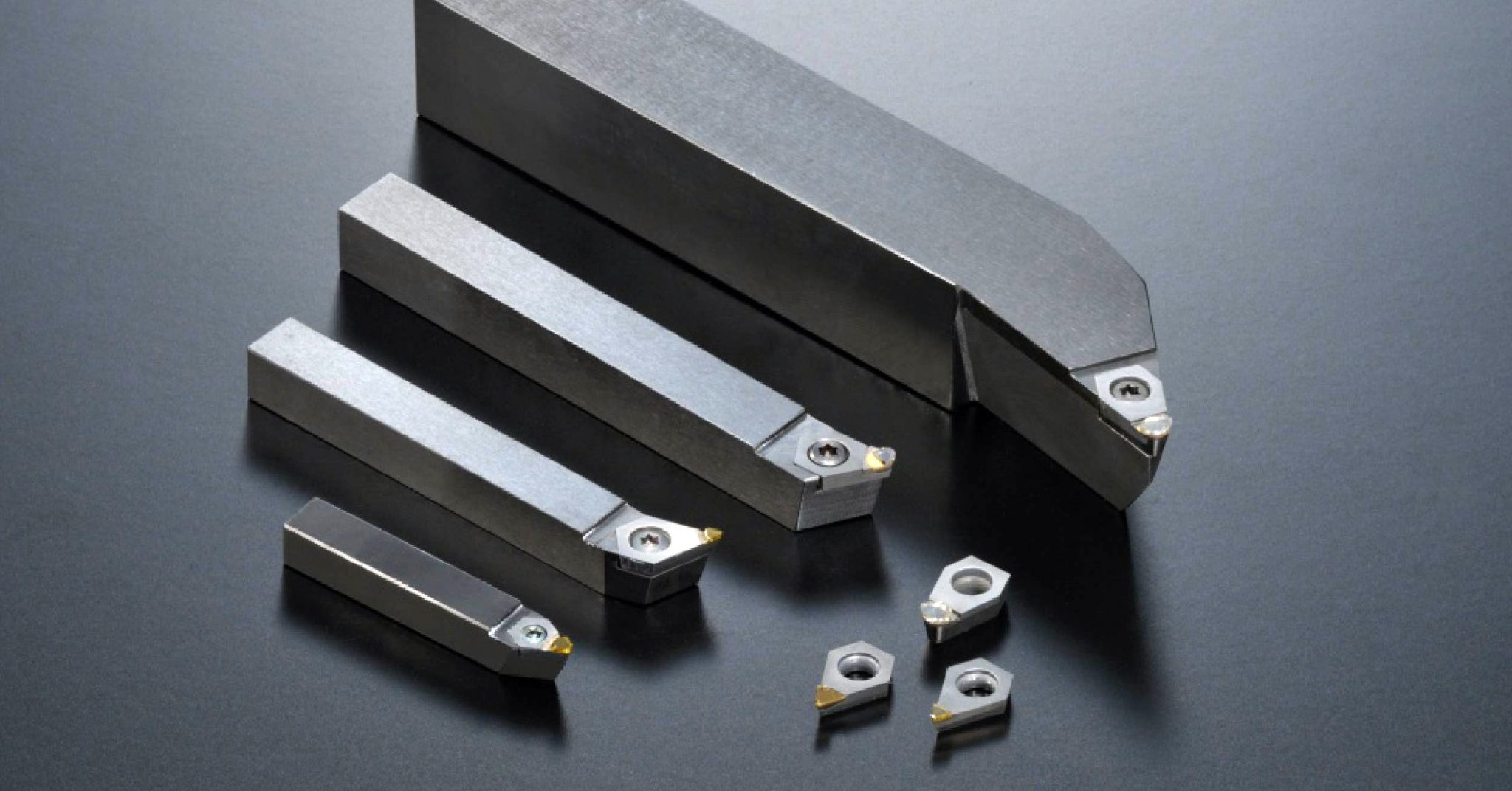

Traditional machining uses cutting tools harder than the workpiece material to remove material through direct interaction.

This method can be applied to many materials, but precision largely depends on operator skill. It is less suitable for high-hardness materials or applications requiring strict quality standards.

Precision machining (CNC machining)

CNC (Computer Numerical Control) machining is a modern method that combines advanced machinery with integrated software control.

It offers high flexibility and automation, making it one of the most widely applied machining methods today. CNC machining works with a wide range of materials and parts, improving both product quality and production efficiency.

View more: Precision CNC Machining Services – Custom Parts for Every Industry

Mechanical processing process

Step 1: Review technical drawings

Mechanical engineers conduct research and analyze technical drawings, select input materials and determine appropriate processing methods.

Step 2: Determine the production method

In mechanical processing today there are 3 main production methods, including:

- Single production: For low-volume, specialized products requiring meticulous, high-precision processing.

- Batch production: For products ordered in predetermined quantities with regular frequency.

- Mass production: For high-volume, continuous production over extended periods.

Step 3: Selecting blanks and blank manufacturing methods

Engineers choose appropriately sized blanks to optimize material use and processing costs. Materials may include metals, alloys, or non-metals.

Step 4: Determine technology and worker level for each step and perform mechanical part processing

Based on the material and process, engineers select the appropriate technology, equipment, and worker skill level to ensure quality and compliance with technical standards.

Step 5: Product quality control

Finished products are inspected for dimensional accuracy and surface finish. Tools used include calipers, bore gauges, coordinate measuring machines (CMM), roughness testers, micrometers, and other precision instruments.

THACO INDUSTRIES – Leading group in the field of mechanical processing

With more than 20 years of experience, THACO INDUSTRIES is proud to be Vietnam’s leading mechanical engineering corporation. The Corporation operates the country’s largest mechanical complex, covering 17.4 hectares, with an investment of over USD 231 million and a steel warehouses capacity of 200,000 tons.

To meet diverse customer needs in both domestic and international markets, THACO INDUSTRIES has invested in a state-of-the-art production line with a closed process: Processing – Welding – Surface treatment & Painting – Assembly. The facility is capable of producing up to 390,000 mechanical products per year.

Our products are trusted in key markets such as the United States, Australia, Canada, and Europe, affirming our reputation as a reliable and world-class mechanical processing partner.

View more: High-quality manufacture and assembly of parts solutions

This article provided an overview of mechanical processing, its methods, and its importance in modern manufacturing. For consultation, support, or to partner with a trusted mechanical processing unit, please contact THACO INDUSTRIES.