Mechanical Processing

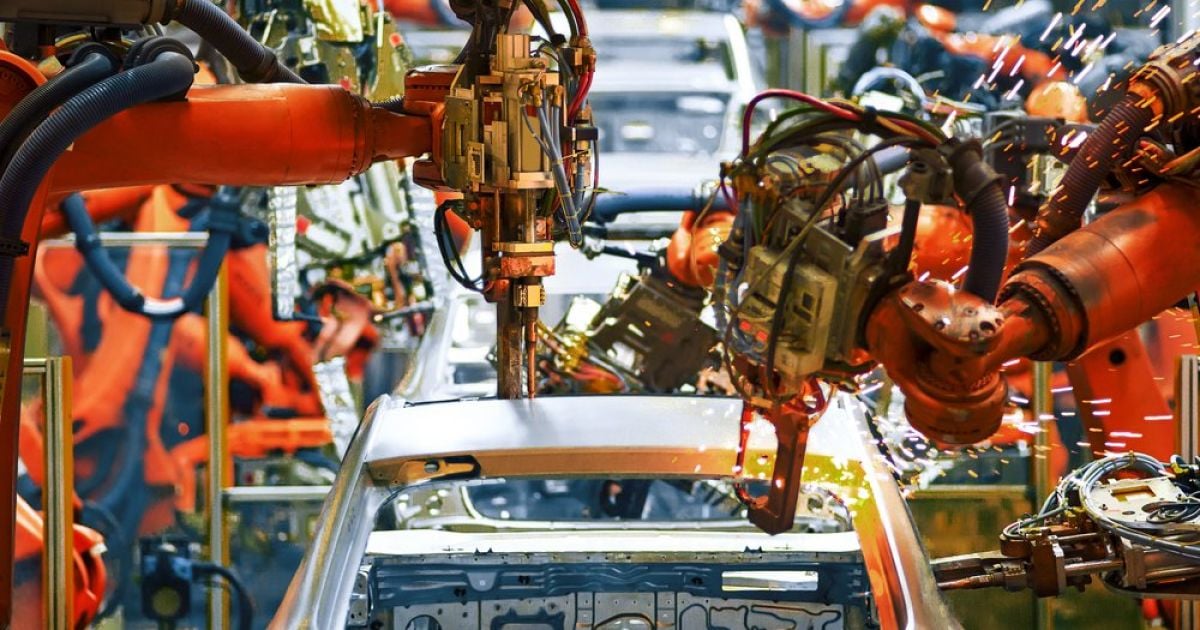

Applications of Precision Machining in the Automotive Industry

Today, in automotive engineering enterprises, precision machining is widely applied. With modern machinery and production lines, this method delivers parts with near-perfect accuracy. Learn how precision machining is being applied in the automotive industry.

What is precision machining?

Precision machining (also known as CNC machining) is the process of using advanced machines and tools to produce highly accurate components for industries such as automotive, dentistry, defence, and healthcare. Supporting equipment and tools include CNC wire-cutting machines, CNC milling machines, CNC lathes, etc., together with high-speed, high-power robots and precise techniques.

Advantages of precision machining

Precision machining delivers many benefits for customers and manufacturers, including:

- Compatibility with most materials, especially high-hardness materials.

- Fast processing, meeting large-volume product demand from customers.

- Reduced input costs due to broad material compatibility, along with support for detailed design, G-code preparation, and simplified material selection.

- Capability to manufacture complex parts that meet quality requirements with a high-quality finish.

Applications of precision machining in the automotive industry

Precision machining plays an important role in the automotive industry. Below are some of the most common applications:

- Manufacturing and machining engine components, including pistons, camshafts, cylinders, valves, and engine housings. Precision processing of these parts ensures high durability and accuracy, influencing performance and extending engine life.

- Producing vehicle frames and suspension components such as chassis, shock absorber assemblies, control arm assemblies, stabilizer bar assemblies, and other parts.

- It ensures high accuracy for braking system components such as brake discs and pads, enhancing load resistance and delivering superior performance and safety.

- CNC machining drivetrain components such as transmissions, axles, crankshafts, and drive units to ensure precise fits, improving system reliability and efficiency.

- In vehicle development, CNC machining is employed to create prototypes and molds for testing, verification, and production of new parts, helping shorten development time and reduce costs.

View more: 5-Axis CNC Machining: High-Precision Solutions

Workpiece machining process for automotive mechanical components

Machining workpieces for automotive mechanical components is the process of producing component workpieces from raw materials such as steel, aluminium, cast iron, and other metal alloys. It typically includes the following steps:

Design and machining plan

Automotive engineers and designers develop detailed technical drawings for the workpieces to be machined. These drawings specify the dimensions, shapes, and precision requirements of the components.

Material selection

Based on technical requirements and the necessary properties of the component, suitable materials are selected for machining the workpieces. Common materials include carbon steel, alloy steel, aluminum, and other alloys.

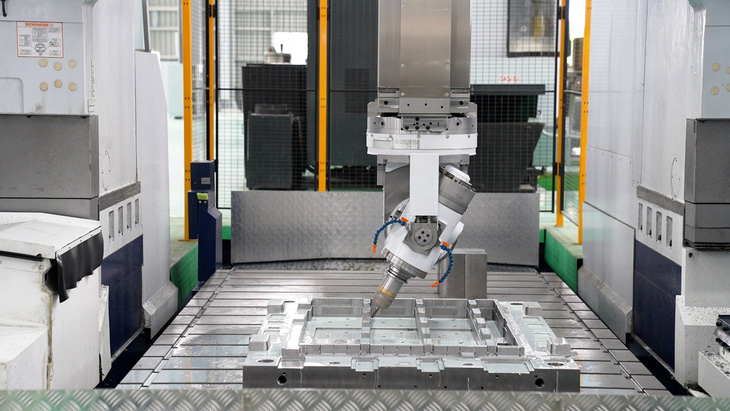

Turning and machining

The machining process for automotive component workpieces typically includes turning, milling, planing, grinding, and other operations. These operations are performed on CNC lathes and other precision equipment to ensure components achieve the required shapes and dimensions.

Surface finishing

After basic machining, components undergo surface finishing to improve properties and appearance. Methods include electroplating, metal plating, coating/painting, chrome plating, matte finishing, and knurling/serration.

Quality inspection

Components must pass quality inspection to ensure they meet technical requirements before use. Inspections include dimensional checks, measurements, material quality testing, and verification of mechanical properties.

THACO INDUSTRIES – A leading precision machining provider today

With more than 20 years of experience in manufacturing and machining, significant investments in technology, and strong R&D activities, THACO INDUSTRIES (a Sub-holding of THACO ) supplies high-tech mechanical products for multiple sectors, including automotive, industrial, agriculture–forestry, construction, and civil applications.

The corporation provides end-to-end solutions – from design, material selection, and cutting to fabrication, welding, painting, assembly, and delivery – saving time and optimizing costs for customers.

Equipped with advanced technologies such as automated welding robots, fibre-laser cutting machines, 5-axis CNC milling machines, Hydraulic die-spotting press machines, CNC gun drilling machines, 2-heads EDM machines, and wire-cutting machines, the corporation delivers high-quality products with outstanding precision at a competitive cost.

View more: CNC Machine Company – Custom Parts for Every Industry

This article has outlined the key Applications of Precision Machining in the Automotive Industry.” For detailed consultation and support, please contact our hotline at (+84)348620063 for prompt assistance.