Product information

Semi-trailer leaf springs: Structure, function and maintenance

The semi-trailer spring suspension is a key part of the vehicle’s suspension system. It functions as ashock absorber, helping maintain balance and ensuring smooth movement on all terrains. Understanding the structure, functions, and maintenance of the spring suspension helps optimize transport efficiency, extend vehicle durability, and guide customers in selecting suitable replacement parts when needed.

What is a semi-trailer spring suspension?

The semi-trailer leaf spring suspension is a vital component of the suspension system, typically made from multiple steel spring leaves. In some cases, semi-trailers may also use air suspension for improved elasticity. Its function is to absorb shocks and balance loads, ensuring smooth, stable operation and enhancing load-bearing capacity.

Functions of the semi-trailer spring suspension

The semi-trailer spring suspension enhances vehicle performance and durability during cargo transport with the following advantages:

- Shock absorption: When traveling on rough roads, the spring suspension absorbs and reduces road impacts on the chassis, ensuring smooth and safe operation.

- Load balancing: It evenly distributes loads across the chassis, enabling the semi-trailer to carry heavy loads without compromising stability.

- Stability improvement: Its flexibility helps enhance stability, reducing risks of rollover or loss of control, especially on challenging terrains.

Common types of semi-trailer suspensions

Leaf spring

The most common type, designed with stacked steel leaves. Simple in design, highly durable, affordable, and easy to maintain or replace. However, it offers lower shock absorption compared to other suspension types.

Parabolic spring

Made from parabolically shaped steel leaves – thin in the center and thicker at the ends – allowing better load distribution and higher load capacity. The drawback is its higher production cost, and when damaged, full replacement is usually required.

Air suspension

This type uses inflatable airbags instead of steel leaves, providing elasticity, smoother rides, and improved stability. Its drawbacks are higher installation and maintenance costs, and the airbags are prone to leakage and damage.

Coil spring

Coil spring suspensions offer durability, effective shock absorption, and flexibility for smoother rides. However, coil springs are expensive, require complex maintenance, and are unsuitable for heavy loads.

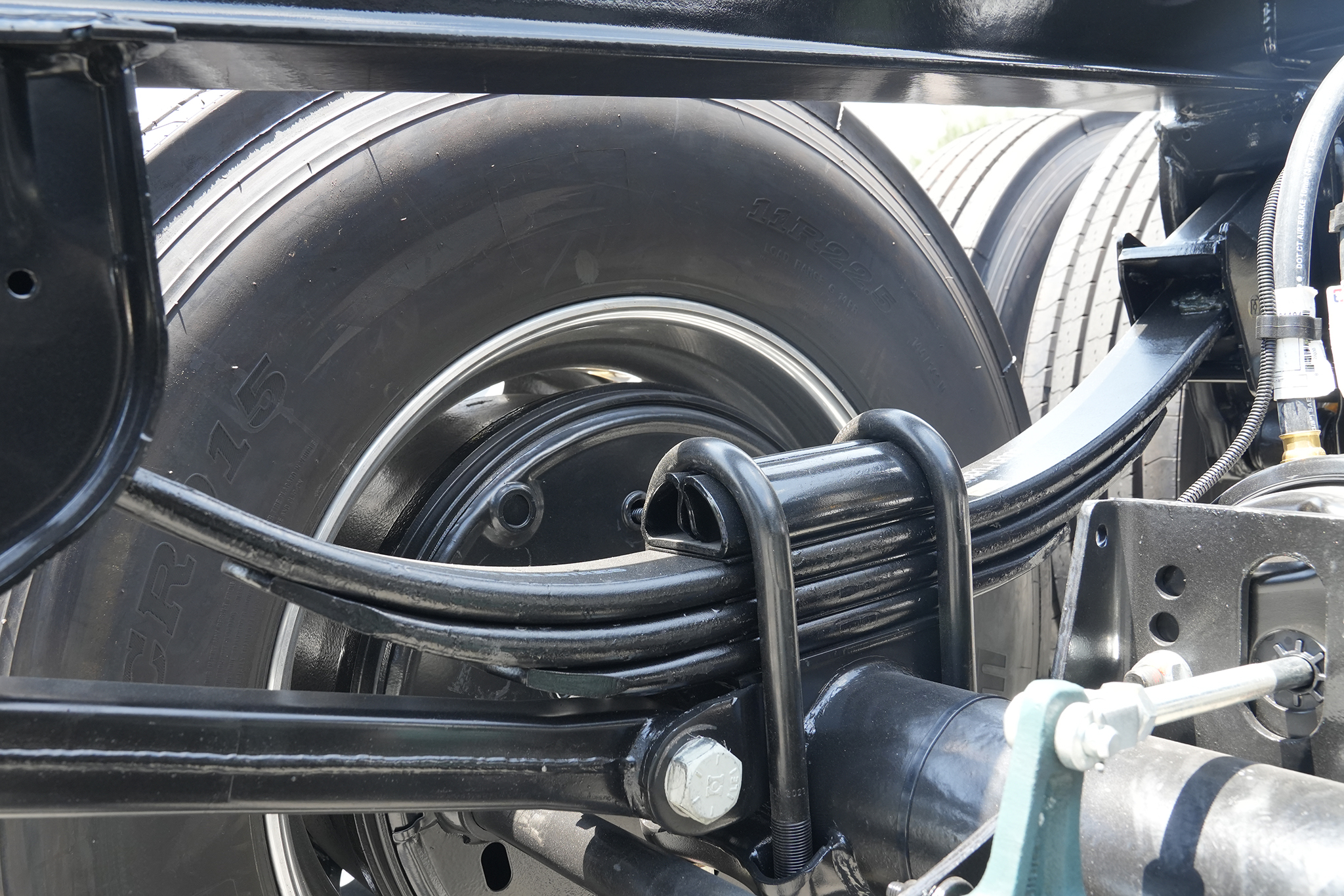

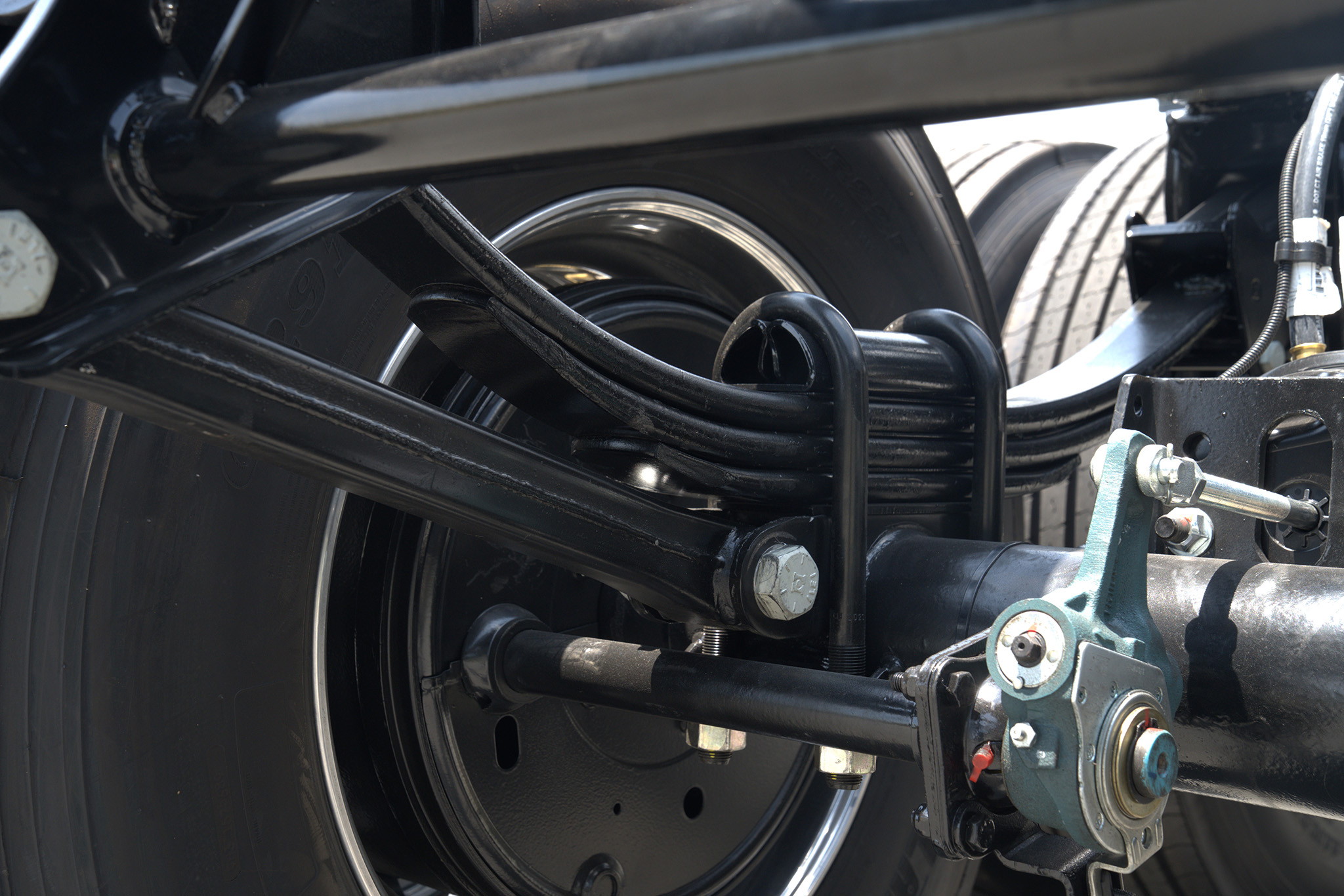

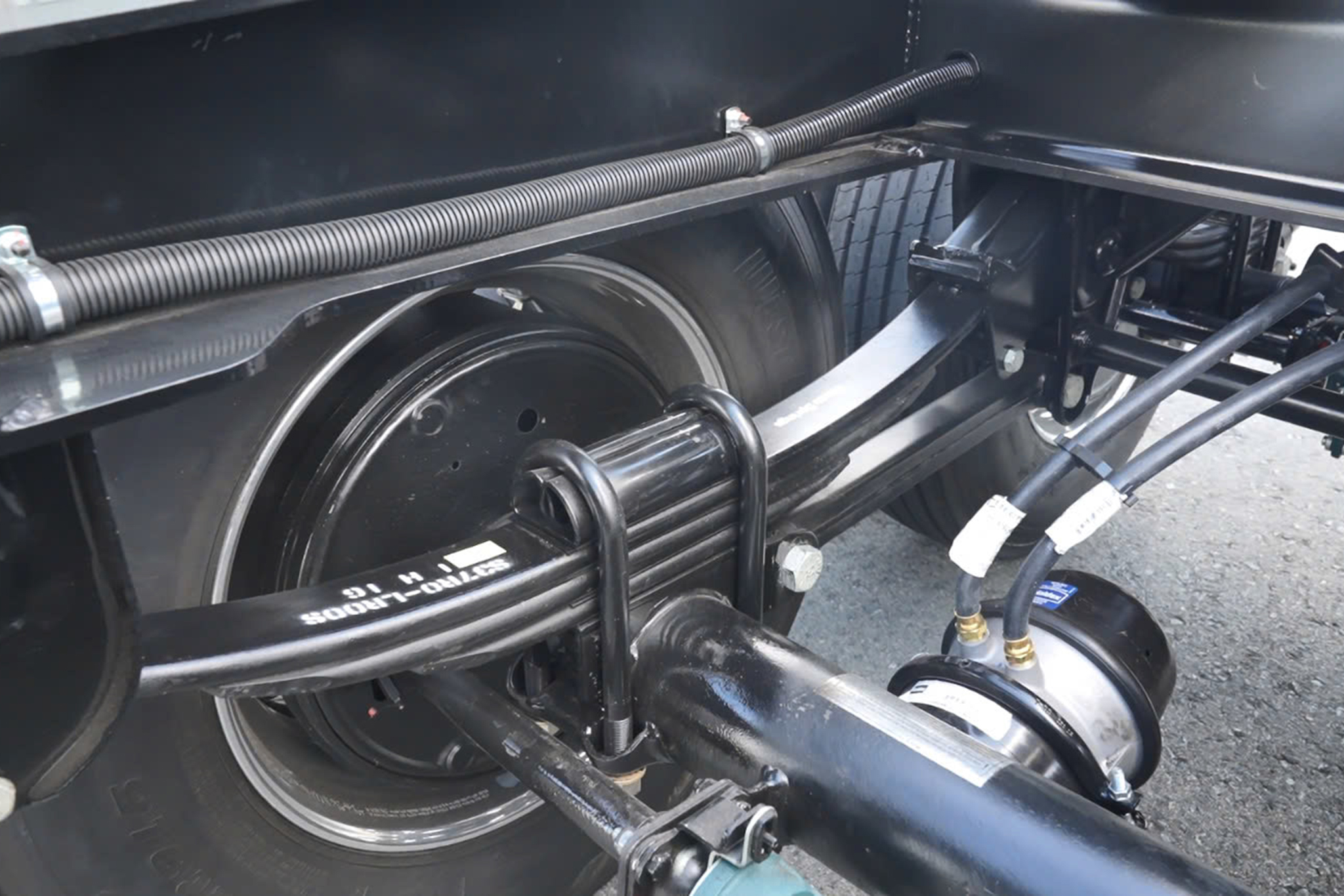

Structure of semi-trailer leaf springs

A semi-trailer leaf spring suspension typically consists of the following parts:

- Spring leaves: Flat, curved, high-elastic steel strips stacked from shortest to longest. The number of leaves varies depending on load requirements.

- Spring clamps: Secure the spring leaves at fixed points (usually ends or center) to prevent shifting during operation.

- U-bolts: U-shaped bolts that fix spring leaves to the axle or other suspension parts.

- Spring pads: Placed between leaves or between leaves and axle to reduce friction and improve ride comfort.

- Bushings: Small bearings or sleeves that reduce friction at joints between spring leaves and chassis.

- Spring pins: Small sleeves or bearings that minimize friction at the joints between spring leaves and the chassis.

Signs your semi-trailer spring suspension needs inspection and maintenance

Suspensions are critical in heavy trucks and semi-trailers. Regular inspection and maintenance are essential for safety and performance. Signs include:

- Unstable movement: Excessive swaying or imbalance on uneven roads may indicate worn or weakened springs.

- Unusual noises: Noises under the chassis may suggest bent, cracked leaves or loose bolts/nuts.

- Bent, cracked, or broken leaves: Deformed leaves must be replaced immediately to avoid load failure.

- Uneven tire wear: May indicate suspension issues, including faulty springs reducing vehicle balance.

- Leaning under heavy loads: Vehicle tilting to one side may indicate damaged springs or suspension parts.

- Reduced elasticity: Loss of smoothness or increased vibrations under normal loads suggests worn-out springs.

- Dirt and rust: Excessive rust at spring joints should be cleaned or replaced promptly to prevent breakage.

- Loose bolts/nuts: Fasteners must be checked regularly; tighten or replace if loose to avoid damage and ensure safety.

Maintenance and servicing of semi-trailer spring suspension

Inspection intervals

Maintenance depends on usage frequency, terrain, and weather. General schedule:

- Monthly: Surface inspection, welds, and spring tension.

- Every 10,000 km: Check spring deflection, joints, and lubricate connections.

- Every 6 months: Full disassembly, cleaning, detailed inspection, and replacement of faulty parts.

Essential maintenance steps

- Cleaning: Remove dirt, oil, and debris regularly to improve efficiency and extend lifespan.

- Visual inspection: Check for cracks, wear, or deformation. Ensure joints and bolts remain secure.

- Lubrication: Apply specialized lubricants to reduce friction at joints for smoother operation.

- Replacement: Replace broken or deformed springs immediately to ensure safety.

- Maintenance tracking: Record all servicing and part replacements for easier monitoring and early fault detection.

View more: Differences between Semi-trailers vs. Trailers

Thaco Spring – Vietnam’s leading spring suspension brand

As a strategic partner of major domestic and international companies, Thaco Parts (a member of THACO INDUSTRIES) proudly leads Vietnam in spring suspension manufacturing under the Thaco Spring brand. Manufactured on advanced automated lines and strictly quality-controlled in compliance with JIS B 2710 standards, Thaco Spring products deliver superior elasticity, load capacity, smooth performance, and stability on all terrains.

This article has outlined the structure, functions, and maintenance of semi-trailer spring suspensions. If you are looking for a high-quality spring suspension manufacturer, Thaco Parts is your reliable partner in Vietnam.. Contact us today at (+84)348620063 for consultation and support!